Contact biotransformation for petroleum polluted refuse/waste water by ambary nucleolus powder

A technology for oil pollution and kenaf powder, which is applied in the fields of grease/oily substance/float removal device, sustainable biological treatment, adsorbed water/sewage treatment, etc., which can solve the problems of impossibility and difficulty in recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

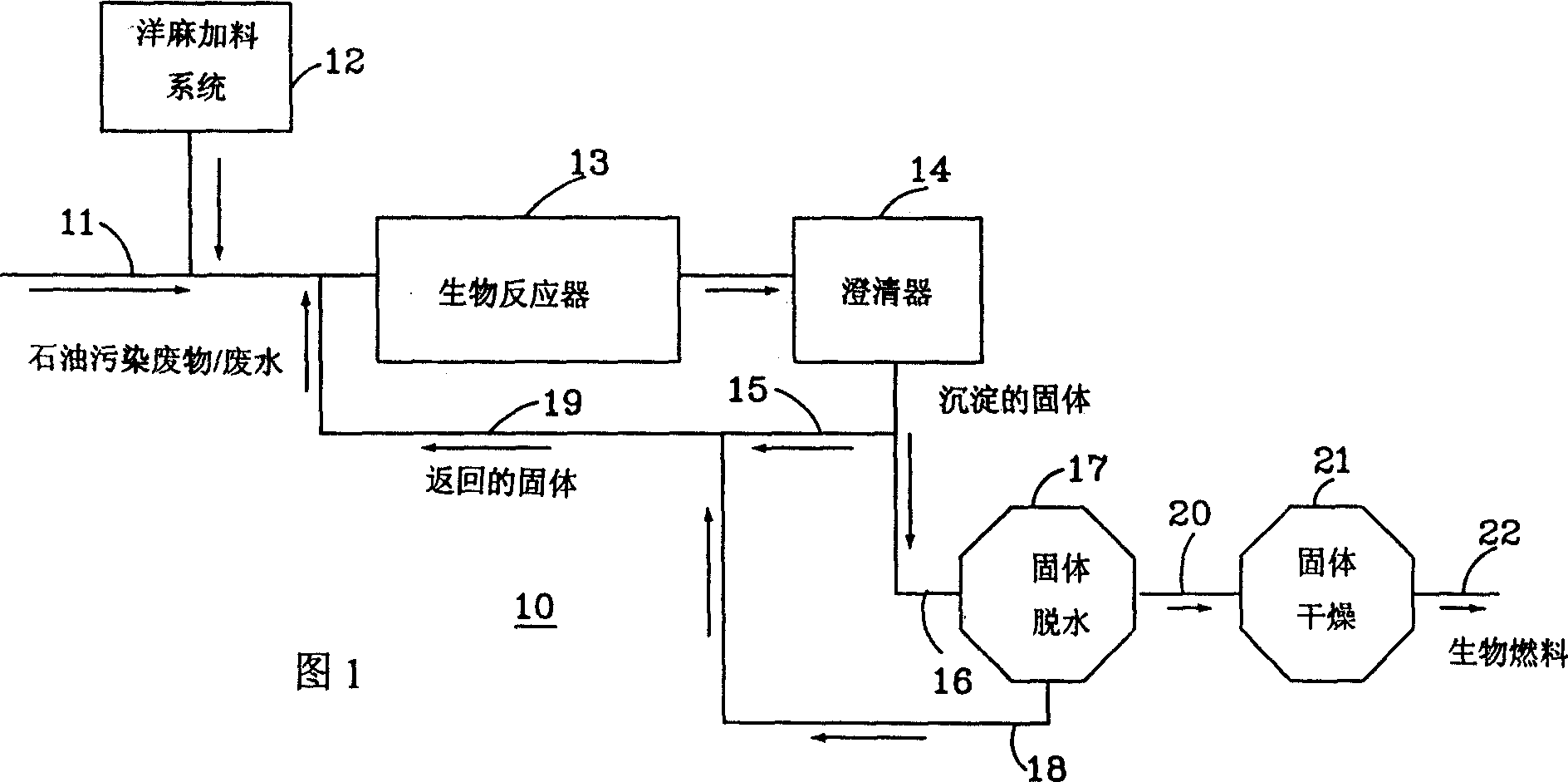

[0015] Figure 1 is a flow chart of the process for injecting kenaf powder 12 into a flowing waste / wastewater stream 11 at an injection rate of 100-5000 mg / L using an in-line injection system. The flow rate of the untreated waste / wastewater stream is typically 5-500 gallons per minute. The kenaf meal combined with the waste / wastewater stream immediately "captures" a portion of the organic load due to its high absorbency. The waste / wastewater stream is mixed with kenaf and then passed into a bioreactor where microorganisms and other components break down the organic matter. The treated liquid is sent to clarifier 14 where solids are separated from the liquid. The solids 16 are pumped to a bio-solids dehydration station, while a portion of the solids 19 (10%-50%) can be returned to the bioreactor 13 for further processing. The solids are dewatered in the bio-solids dehydration station 17, water 18 is then returned to the bioreactor, and the dehydrated solids 20 are processed 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com