8-inch vacuum booster assembly with floating diaphragm structure

A vacuum booster, floating technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of vacuum booster failure, achieve good positioning, improve product reliability, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

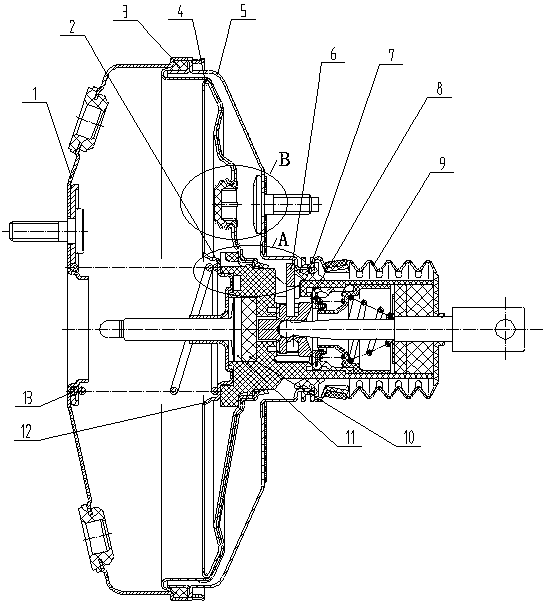

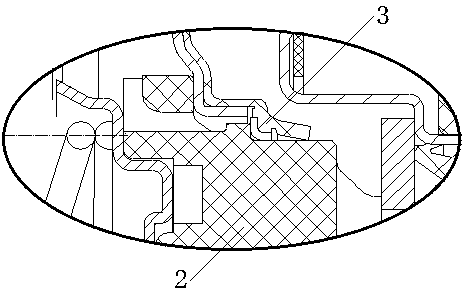

[0014] The front shell part 1 is riveted with the rear shell part 5, the diaphragm 3 is installed between the front shell part 1 and the rear shell part 5, and the rear shell air seal 7 is interference fit with the rear shell part 5 to form a sealed shell , the rear shell air seal 5 is interference fit with the valve body 2, the booster disc 4 is riveted with the valve body 2, the control valve part 8 and the valve body 2 are clamped and assembled through the lock plate 6, the feedback disc 10, the retainer 12, the master cylinder push The rod 11 is fitted inside the valve body 2 , the return spring 13 is fitted on the retainer 12 , and the dust cover 9 is fitted on the rear housing part 5 .

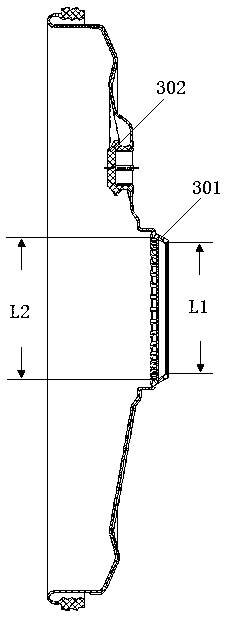

[0015] There is a floating sealing structure 301 and a clamping positioning structure 302 on the diaphragm 3, and the valve body 2 is connected to the diaphragm 3 through the floating sealing structure 301. The floating sealing structure 301 has a sealing ring one L1 and a sealing ring tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com