Channeling measuring method

A channel measurement and consistent technology, applied in the field of petroleum cementing, can solve problems such as cracking of mud biscuits, inability to scientifically reflect the anti-channeling ability of cement slurry, poor replacement efficiency of cement slurry, etc., and achieve the effect of overcoming inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

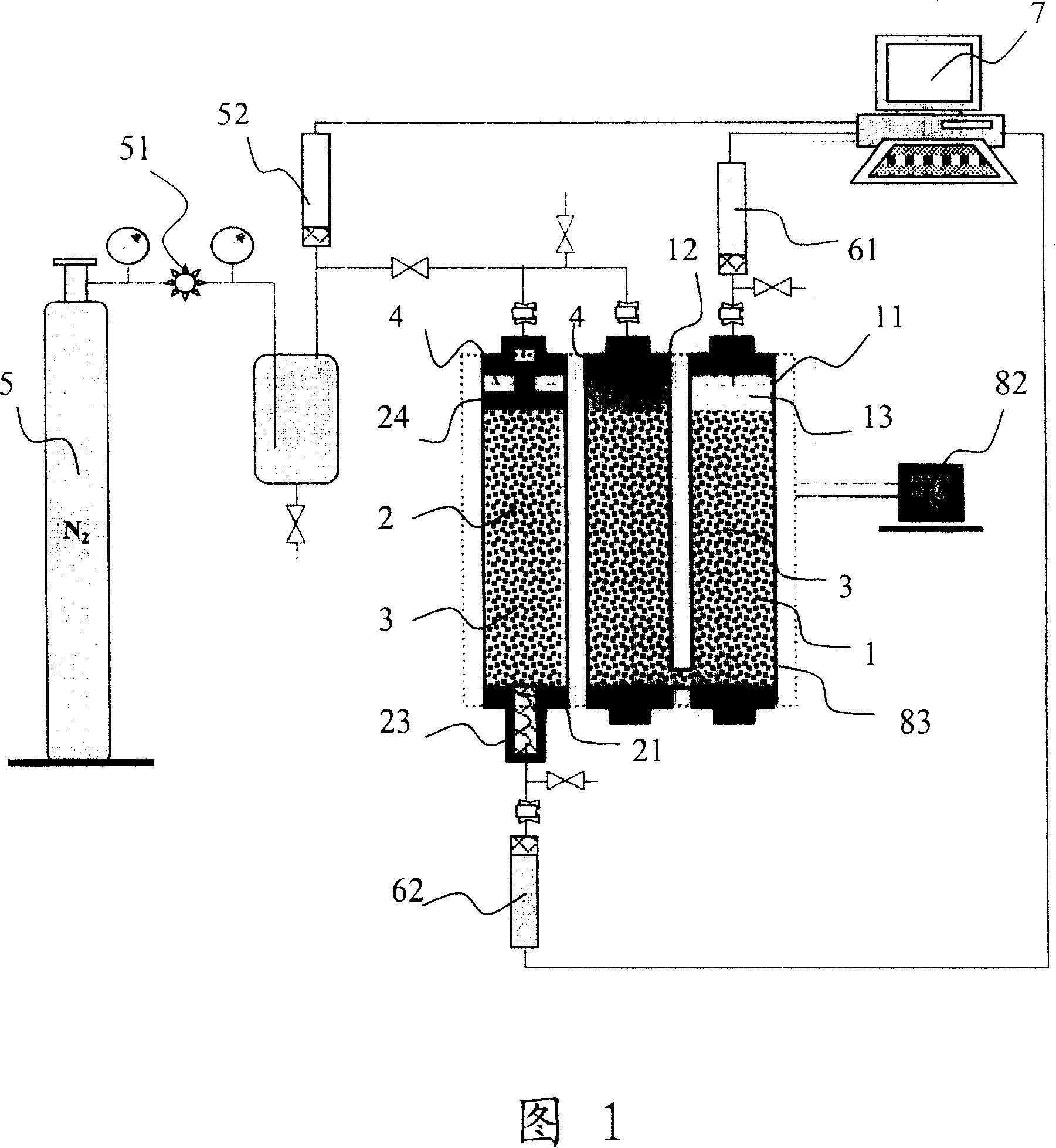

[0055] As shown in Figure 1, the present invention provides a kind of method for measuring channeling, and it comprises the steps:

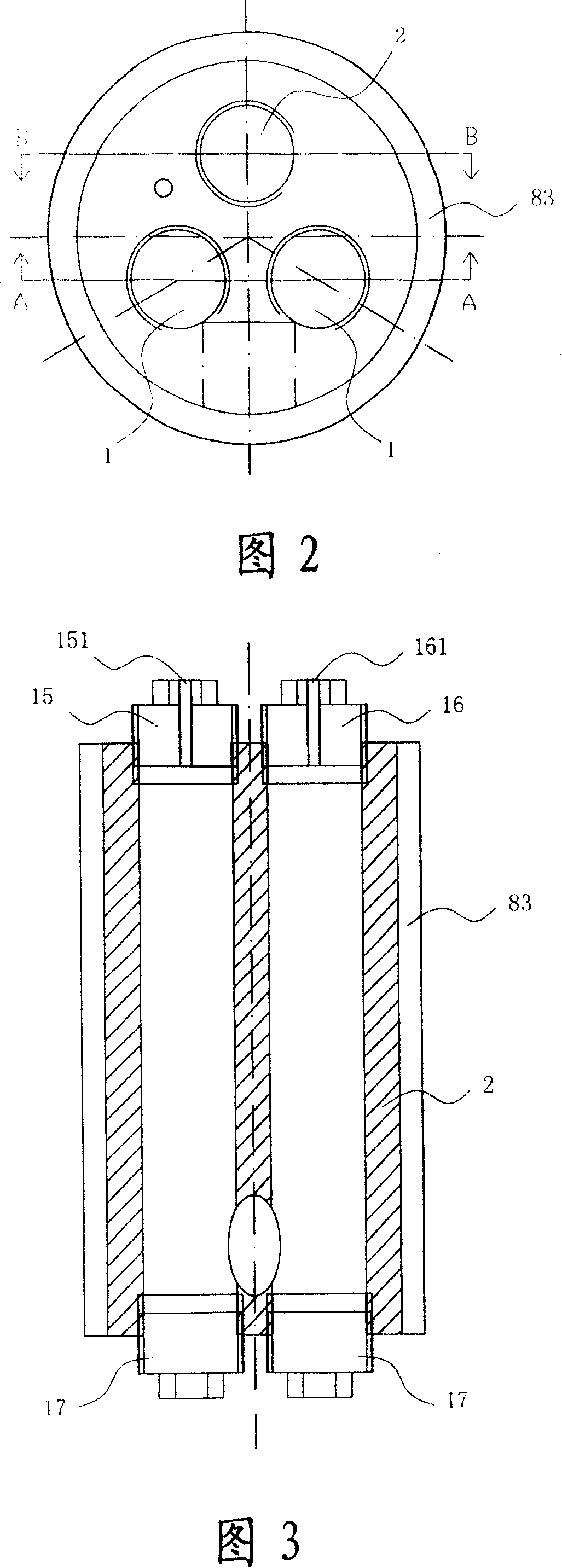

[0056] (1) U-shaped cement slurry cylinder 1 and cylindrical cement slurry cylinder 2 are prepared, and the cylinder diameter of this U-shaped cement slurry cylinder 1 is equal to the cylinder diameter of cylindrical cement slurry cylinder 2;

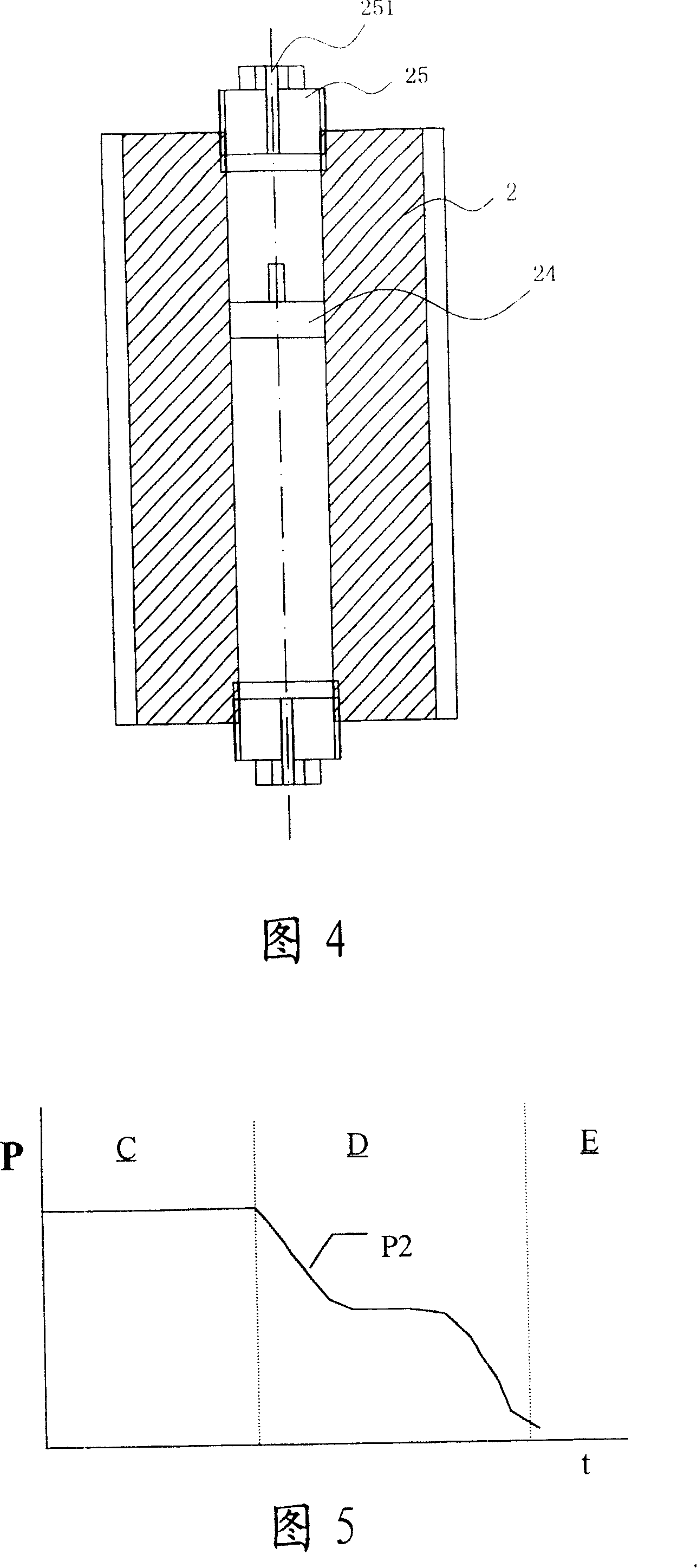

[0057] (2) Add spacer 23 to the bottom 21 of the cylindrical cement slurry cylinder 2, pour the prepared cement slurry 3 into the U-shaped cement slurry cylinder 1 and the cylindrical cement slurry cylinder 2 respectively, and keep the U-shaped cement slurry cylinder 2. The height of the cement slurry column in the cement slurry cylinder 1 and the cylindrical cement slurry cylinder 2 is basically the same;

[0058] (3) Add hydraulic oil 13 to one end 11 of the U-shaped cement slurry cylinder 1, add an isolation piston 24 on the slurry column of the cylindrical cement slurry cylinder 2, and simultaneously c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com