Spray bore slice

An orifice sheet and orifice technology, applied in printing and other directions, can solve problems such as damage to the anti-wetting layer, scratches, and skew in the direction of droplet ejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

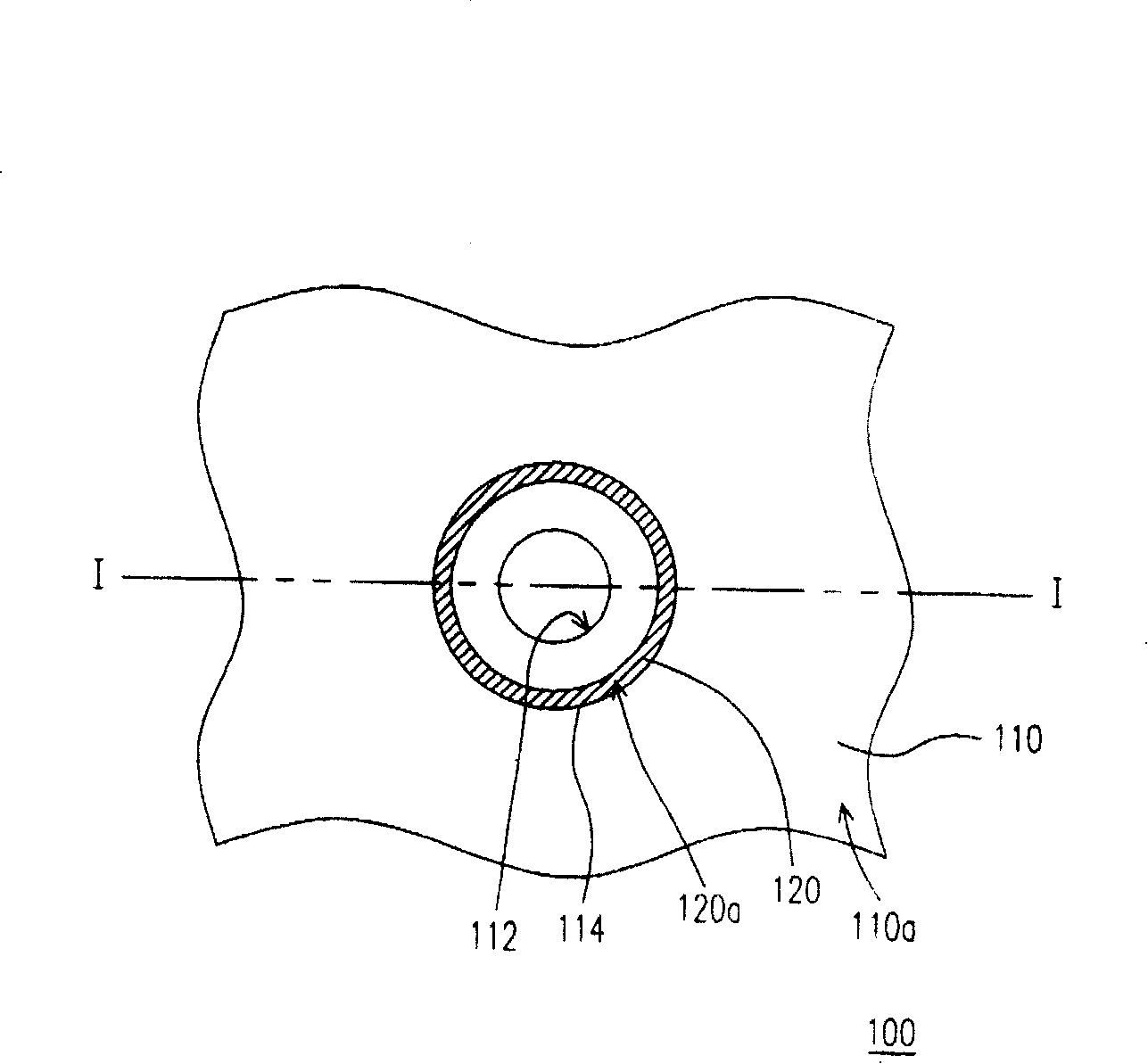

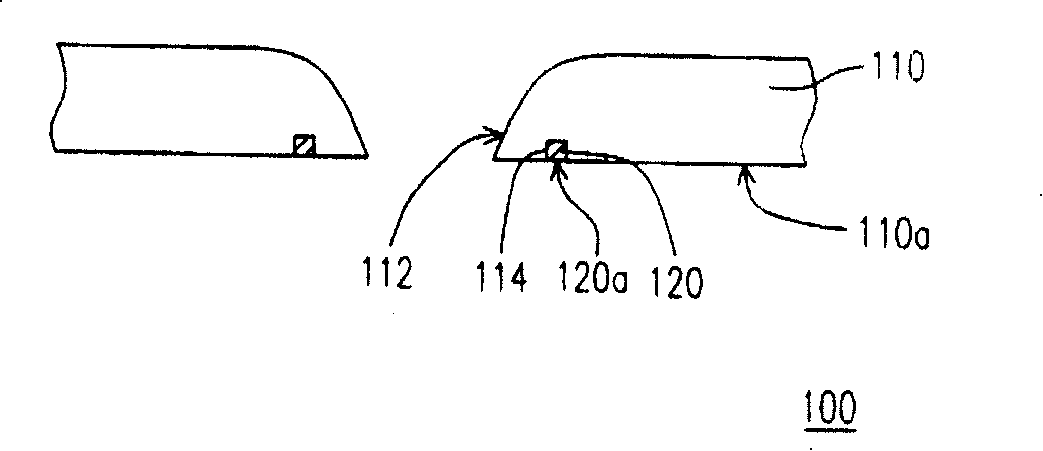

[0073] Figure 1A is a partial top view of an orifice sheet according to the first embodiment of the present invention, Figure 1B for Figure 1A Sectional view of the line I-I. Please refer to Figure 1A and Figure 1B , the orifice sheet 100 of the first embodiment is suitable for an inkjet print head and includes an orifice layer 110 . The orifice layer 110 has an orifice 112 , which runs through the orifice layer 110 , so that the inkjet printing head using the orifice sheet 100 can eject ink droplets or liquid droplets through the orifice 112 .

[0074]In order to prevent the ink or solution remaining on the surface 110a near the nozzle hole 112 of the nozzle hole layer 110 from flowing to other areas of the surface 110a of the nozzle hole layer 110, the nozzle hole layer 110 also has a ditch 114, which is located at the nozzle hole The surface 110 a of the layer 110 also surrounds the injection hole 112 , and the trench 114 is separated from the injection hole 112 by a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap