Seat sliding device

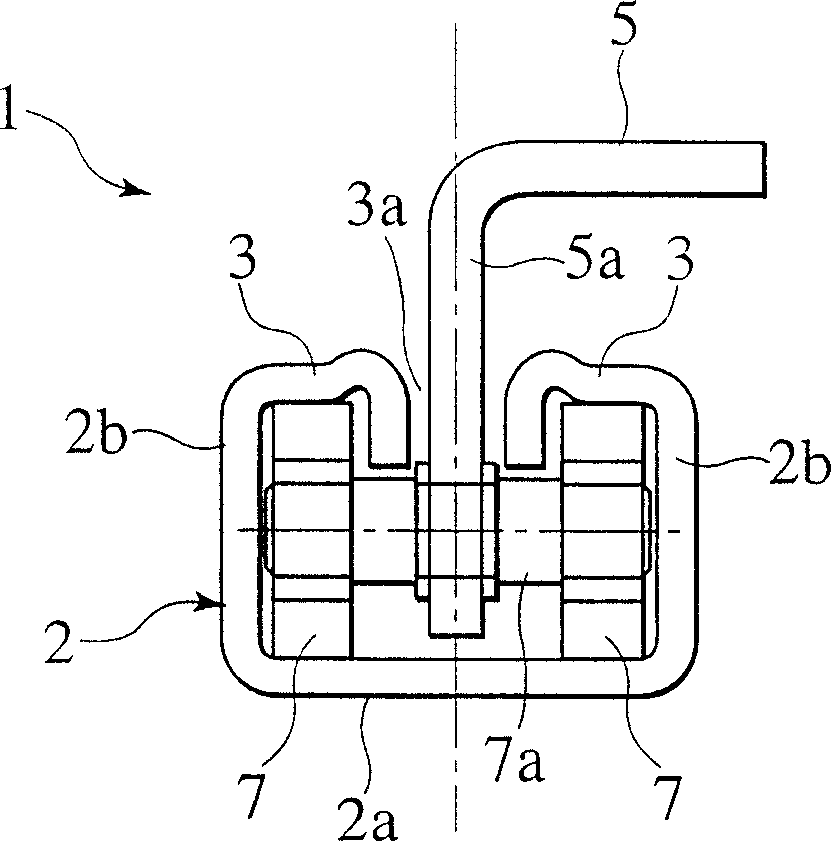

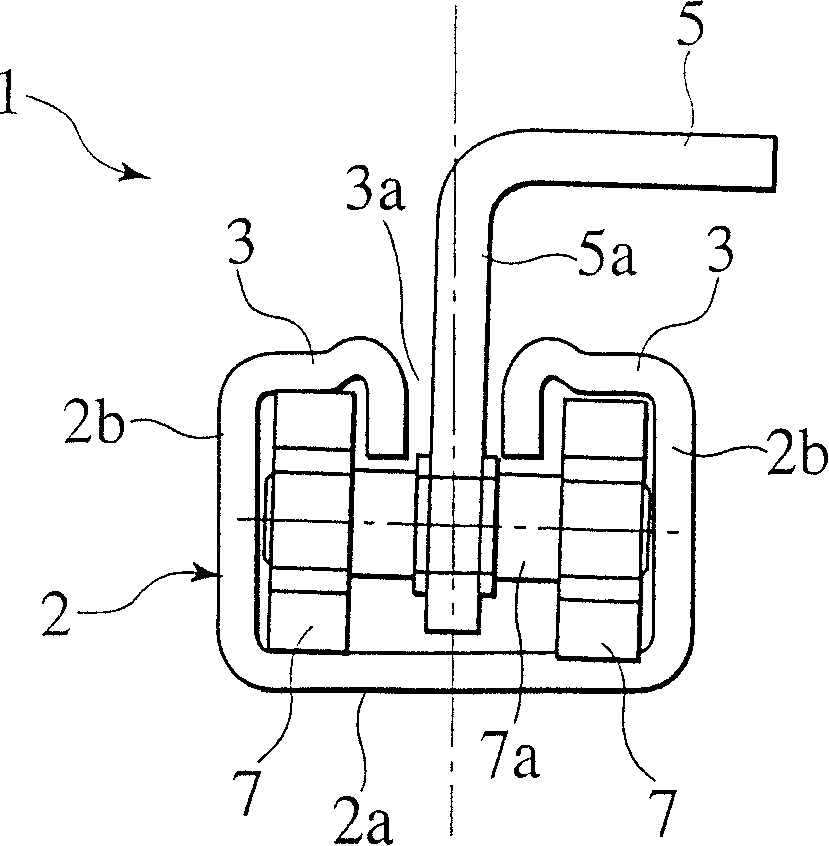

A sliding device and seat technology, applied to vehicle seats, movable seats, chairs, etc., can solve the problems that the upper guide rail 5 cannot slide smoothly, the number of parts increases, and the sliding operation force increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

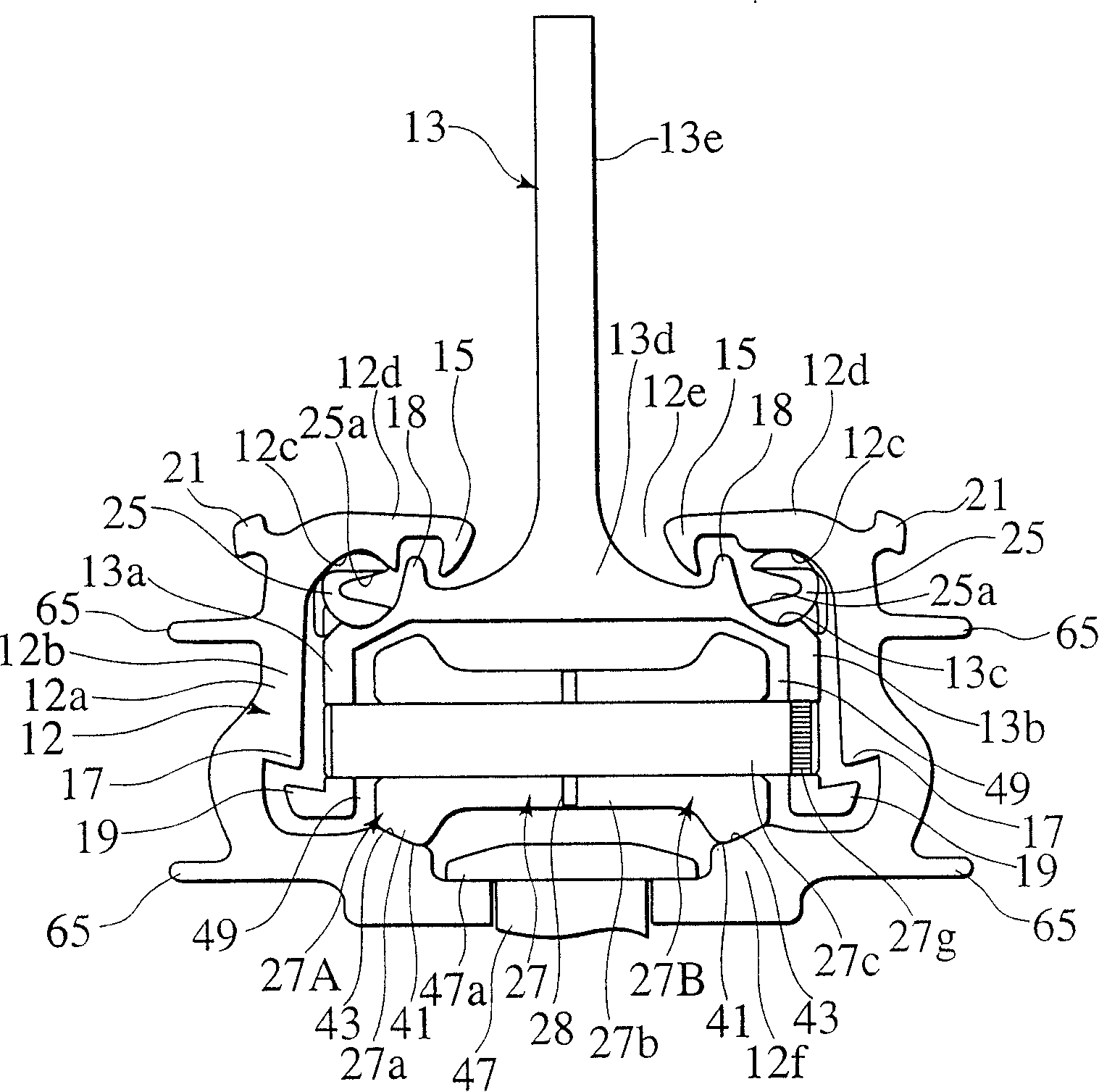

[0052] The second embodiment of the seat sliding device of the present invention will be described in detail below with reference to the accompanying drawings. In this case, the same reference numerals are used to denote the same components as in the first embodiment described above and detailed description thereof will be omitted.

[0053] Such as Figure 7 As shown in and 8, the seat sliding device 1 of the second embodiment is mainly composed of a lower guide rail 12 and an upper guide rail 13 accommodated in the lower guide rail 12. The lower guide rail 12 is installed on the vehicle body floor surface along the longitudinal direction of the vehicle, and the upper guide rail 13 Sliding freely in the longitudinal direction of the vehicle, it is installed on the side of the seat body (not shown) and supports the seat body.

[0054] The lower guide rail 12 is constructed in such a way that a substantially upward C-shaped seat body 12a, a pair of left and right flanges 22 ext...

no. 3 example

[0073] Figure 11 A third embodiment of the seat slide 11 is shown. The same reference numerals denote the same components as in the above-mentioned embodiments, and thus detailed description thereof will be omitted. According to this embodiment, the coil spring 42 for urging the pair of left and right rolling elements 27A and 27B is accommodated in the receiving groove portions 42a and 42b formed in the outer circumferential surfaces of the pair of left and right rolling elements 27A and 27B.

[0074] Therefore, it is possible to measure the gap between the pair of left and right rolling members 27A and 27B, but since there is an elastic force applied to the rolling members 27A and 27B due to the spring elasticity of the coil spring 42, it is possible to effectively eliminate the vehicle body mounting portion and the sliding member. Due to the contact surface between the rolling elements 27A and 27B and the rolling element receiving stepped portion 12f arranged as a concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com