Precast slab bleaches water-proof treating method

A technology of waterproof treatment and prefabricated panels, which is applied to roofs, roofs, buildings, etc. that use flat/curved panels. It can solve the problems of poor waterproof effect, unstable structure, and high cost, and achieve stable effects, significant effects, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

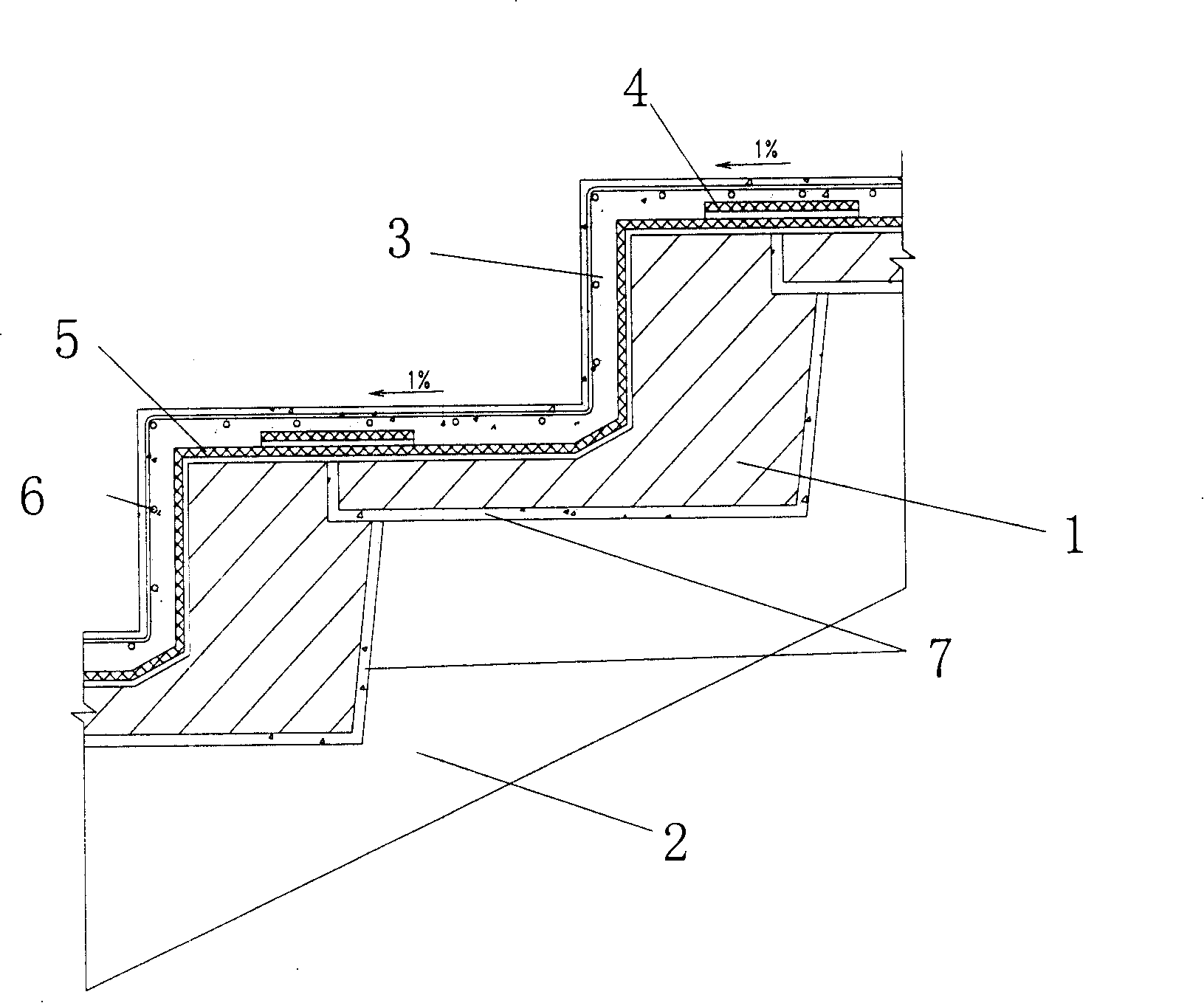

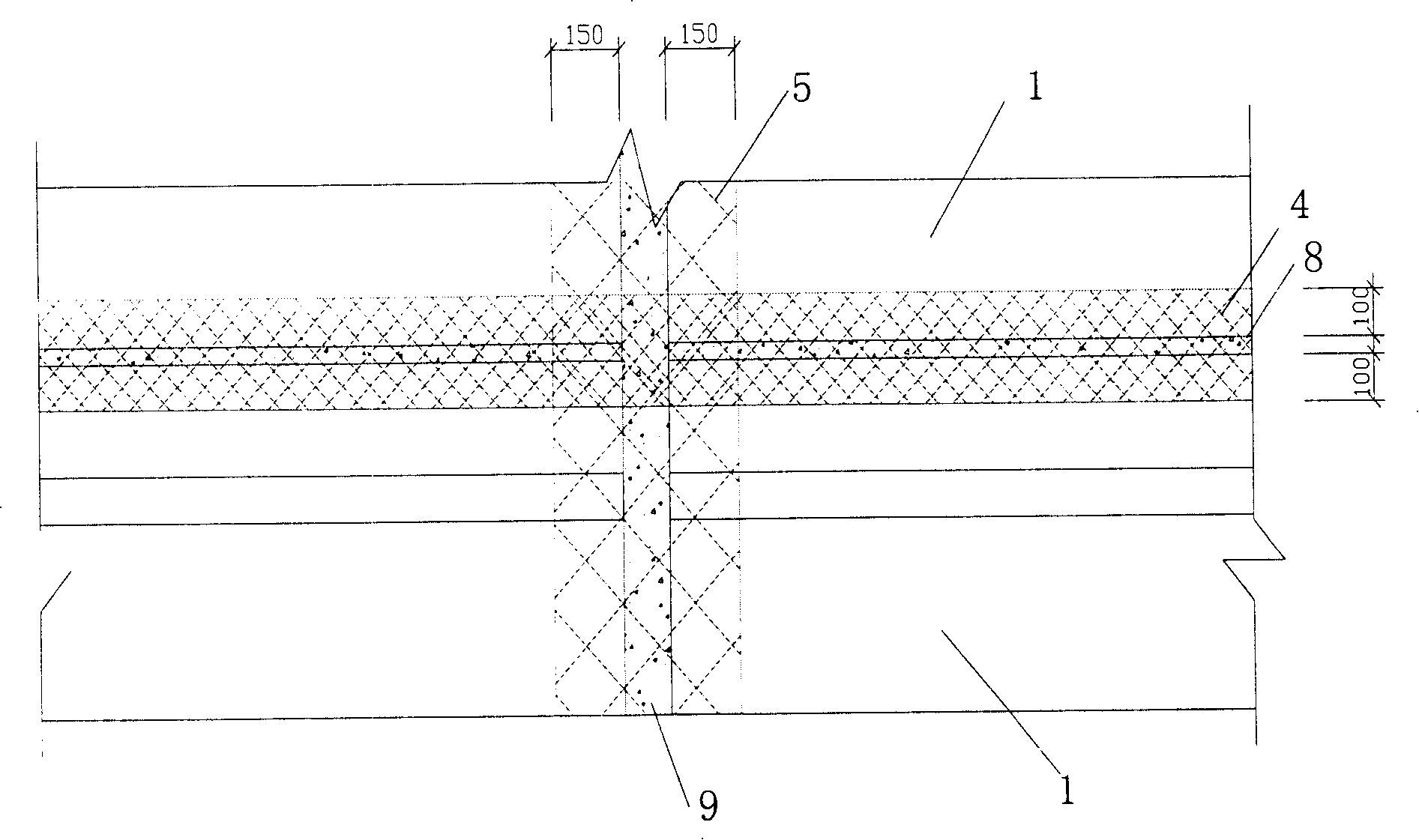

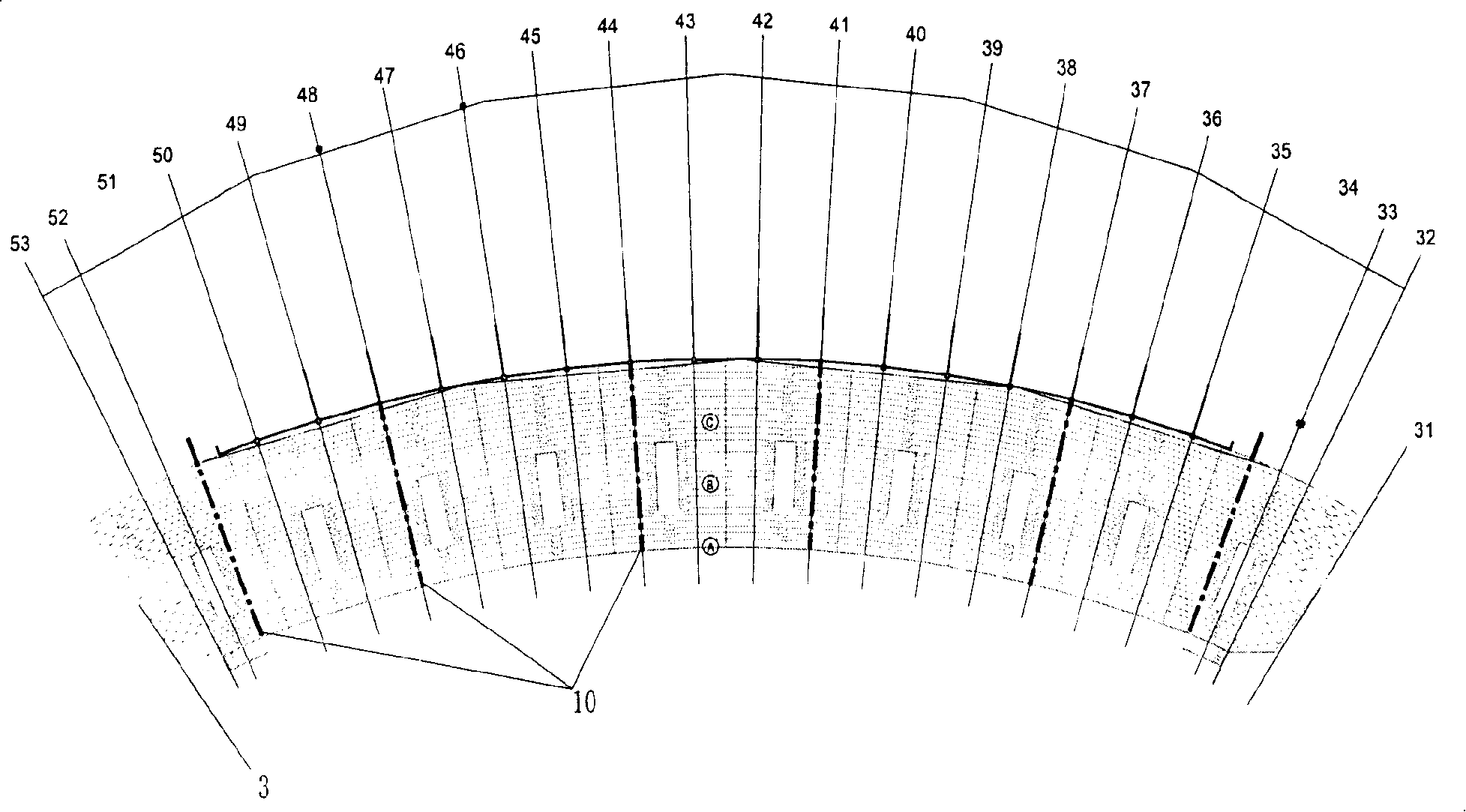

[0027] Such as figure 1 , it can be seen that the basic structure of the local unit of the stand, such as the prefabricated stand slab 1, the reinforced concrete inclined beam 2, the nylon fiber fine stone reinforced concrete surface layer 3 on the prefabricated slab stand slab and the circumferential slab requiring waterproof coating should be pre-designed before waterproofing Seam waterproof layer 4, longitudinal slab seam waterproof layer 5, the role of the concrete surface layer is to assist the waterproofing of the stands, surface decoration, and the base for fixing the seat brackets. In the concrete surface layer, steel bars 6 are bound, or embedded parts, fine stone Reinforced concrete reinforcement is Φ4@150 two-way, C20 fine stone concrete, nylon specification Φ25±3μm, length 16-19mm, breaking strength ≥ 25.9Cn, breaking elongation ≤ 60%, dosage 0.8kg / m3, when configuring concrete When it is added to the mixer together with other materials, the mixing time is 1 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com