Hollow soft drill and its manufacturing method

A hollow and soft drill technology, applied in the direction of the fixer, can solve the problem of inappropriate hollow bone drill, and achieve a simple and effective processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

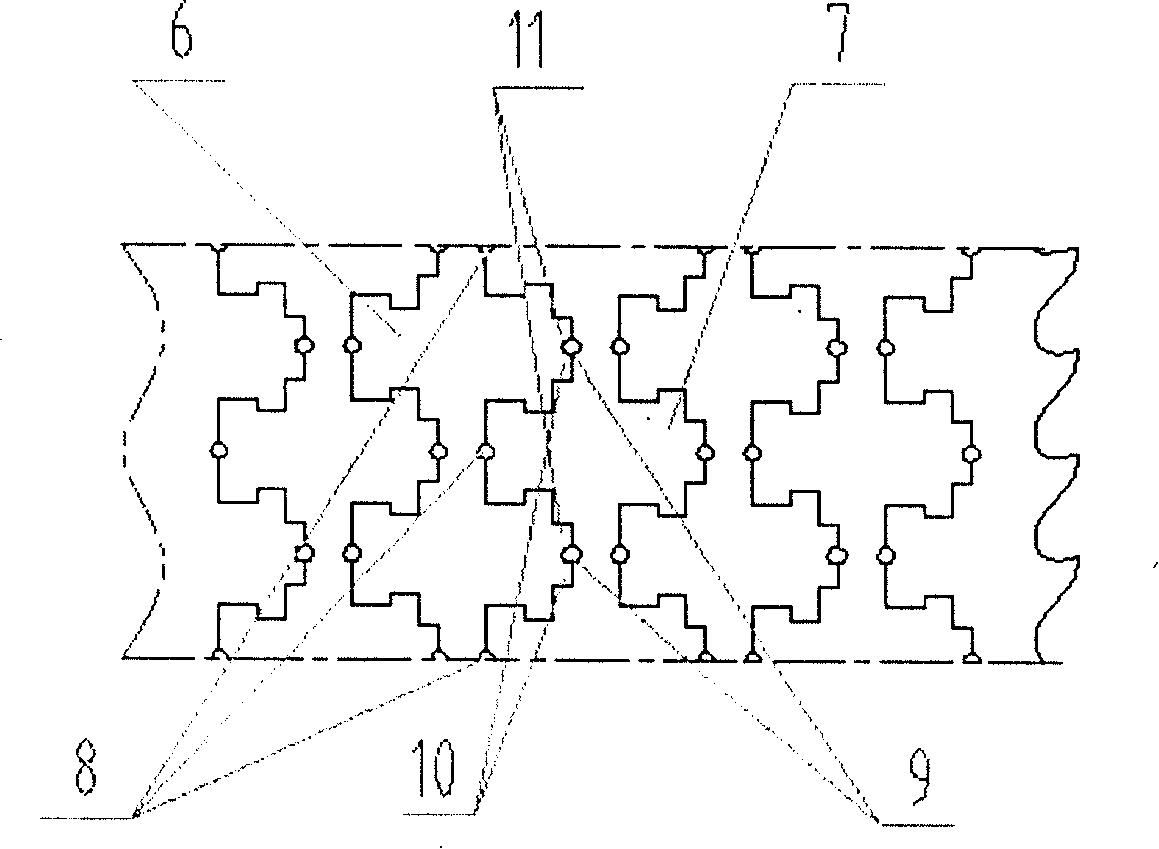

[0009] according to figure 1 As shown, the present invention is made up of drill shank 1, hollow sleeve 4 and cutting edge 2, drill shank 1 is connected with the upper end of hollow sleeve 4 by pin 3, cutting edge 2 is connected with the lower end of hollow sleeve 4, and hollow sleeve 4 is made up of several groups Composed of 5 links.

[0010] according to figure 2 As shown, the hollow sleeve is composed of several groups of chain links, and each group of chain links is composed of two upper and lower horizontal short sections that are not connected, and the middle is long and connected, which is like the word "King". The upper group of chain links 6 and the lower group of chain links 7 are 90 degrees to each other, so that the next cross of the upper chain link 6 is embedded in the space between the upper two crosses of the lower chain link 7, so that the upper and lower chain links 6, 7 are connected to each other. There is a shoulder 10 in the next horizontal of each "W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com