Filtration cartridges with metallic end members and method of manufacturing

An end member, metal casting technology, applied in the field of filter cartridges with metal end members and its manufacturing, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

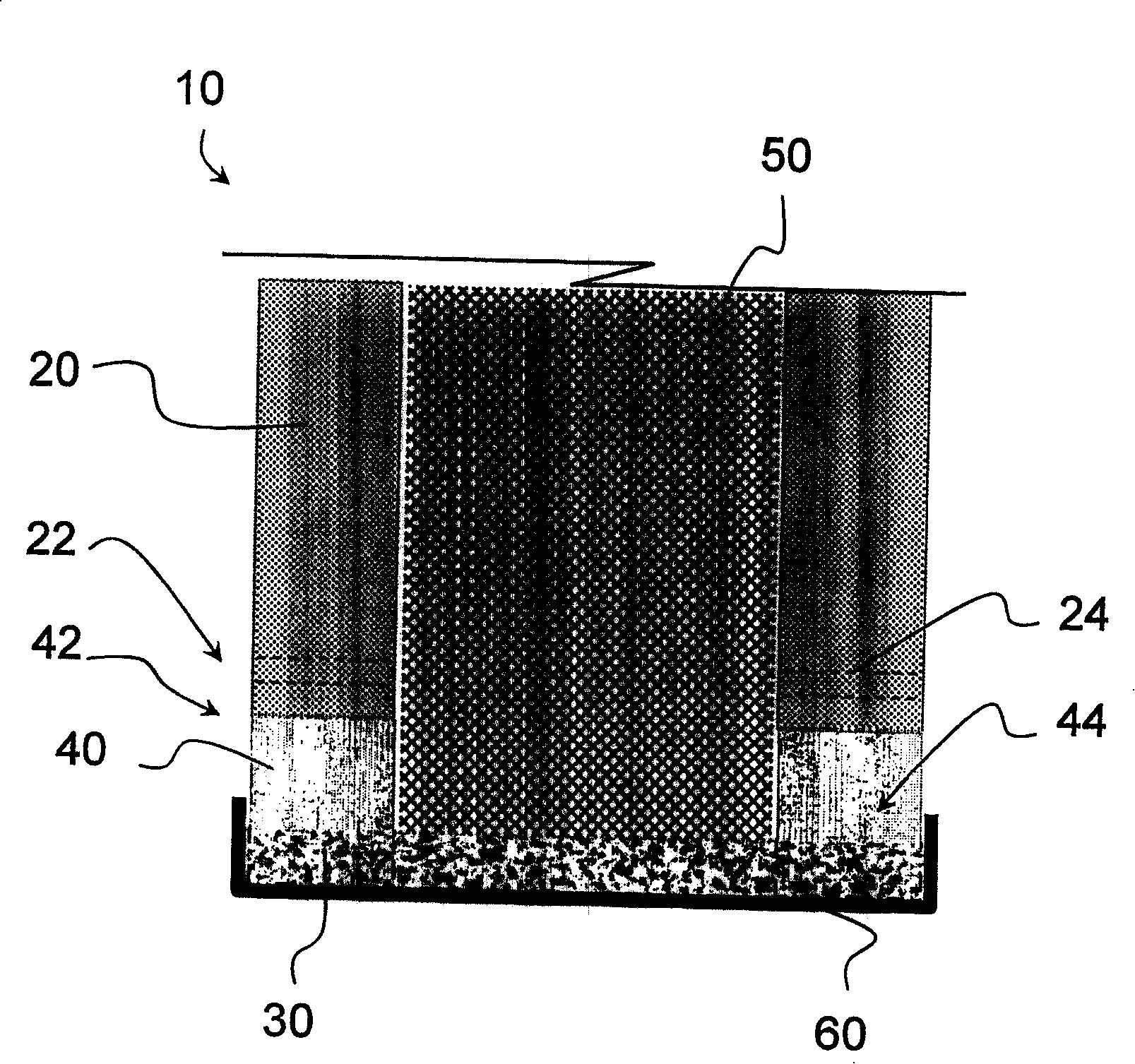

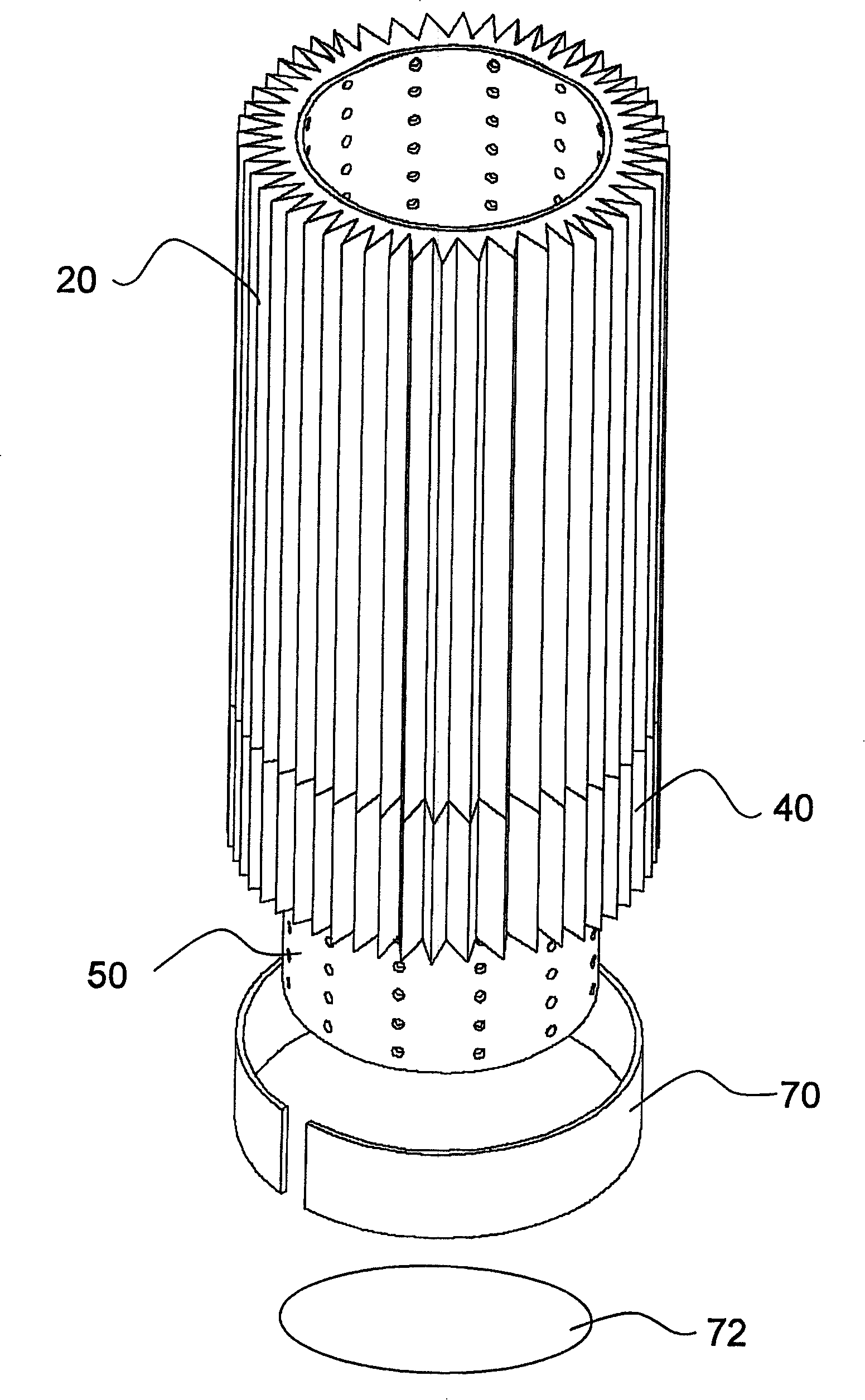

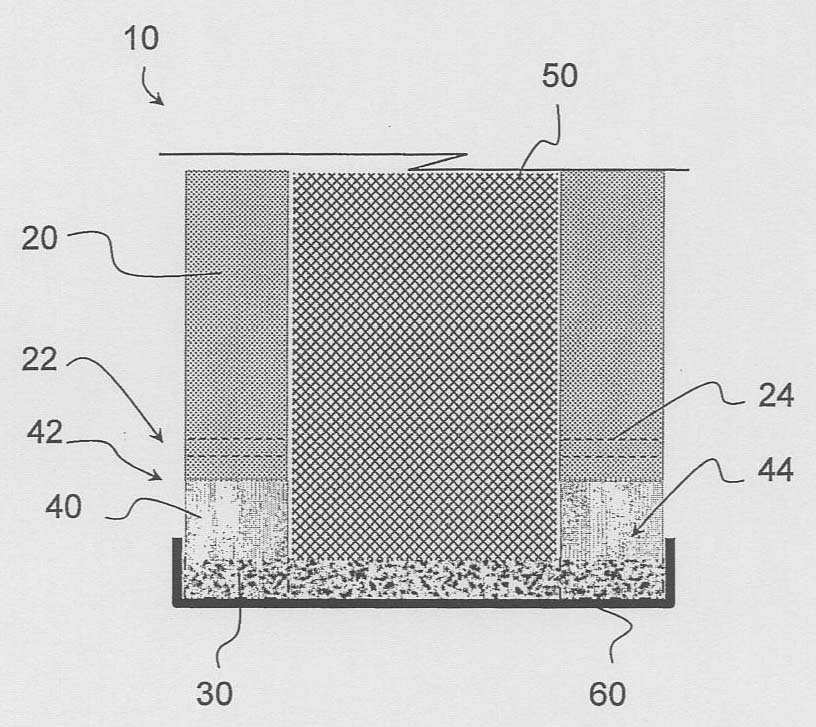

[0016] figure 1 A filter cartridge 10 is shown having a metal end member 30 in accordance with a preferred embodiment of the present invention. figure 2 show figure 1 Alternative embodiments of an embodiment. It should be noted that the invention is not limited to the embodiments shown, but that many other embodiments can be devised without departing from the scope of the appended claims.

[0017] Filter cartridge 10 includes filter element 20 . The filter element 20 is generally in the form of a porous fabric or its equivalent. The filter element 20 is generally arranged in a pleated form to increase the overall surface area. It should be noted, however, that the invention is not limited to pleated filter elements. The most common shape of filter element 20 is that of a hollow cylinder.

[0018] The filter cartridge 10 includes at least one metal end member 30 , although often two metal end members 30 are employed. If the filter element 20 is rectangular, four metal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com