High power square thyristor packaging structure

A high-power, square-chip technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of delamination between the silicone protective layer and the chip, low working reliability, and poor moisture resistance, and achieve product moisture resistance. Enhancement, increased work reliability, avoids the effect of stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

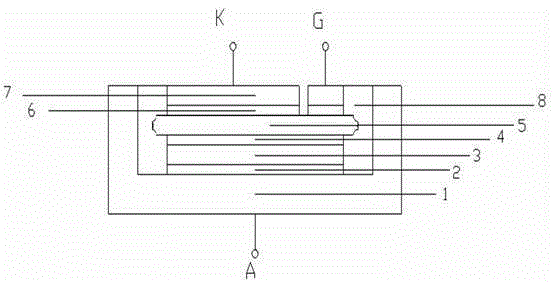

[0015] Such as figure 1 As shown, a high-power square thyristor packaging structure, which includes an upper molybdenum sheet 7, a third solder layer 6, a chip 5, a second solder layer 4, a lower molybdenum sheet 3 and a first molybdenum sheet arranged sequentially from top to bottom A solder layer 2, the aforementioned upper molybdenum sheet 7, the third solder layer 6, the chip 5, the second solder layer 4, the lower molybdenum sheet 3 and the first solder layer 2 are all placed in the silica gel frame 8, and the two ends of the chip 5 are inserted into the Inside the silicone frame 8, a conductive shell 1 is installed outside the silicone frame 8. The conductive shell 1 is a semi-enclosed structure with the top open and the other three sides closed. The bottom of the conductive shell 1 is welded on the high-power square piece. Where the silicon need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com