Processing chamber and processing device

A processing device and processing chamber technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of restraining the expansion of the floor space, restraining the expansion of the external size, and reducing the cost burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described below with reference to the drawings.

[0038] Here, a case where the processing apparatus of the present invention is used as a multi-chamber type vacuum processing system used for etching a glass substrate for FPD will be described.

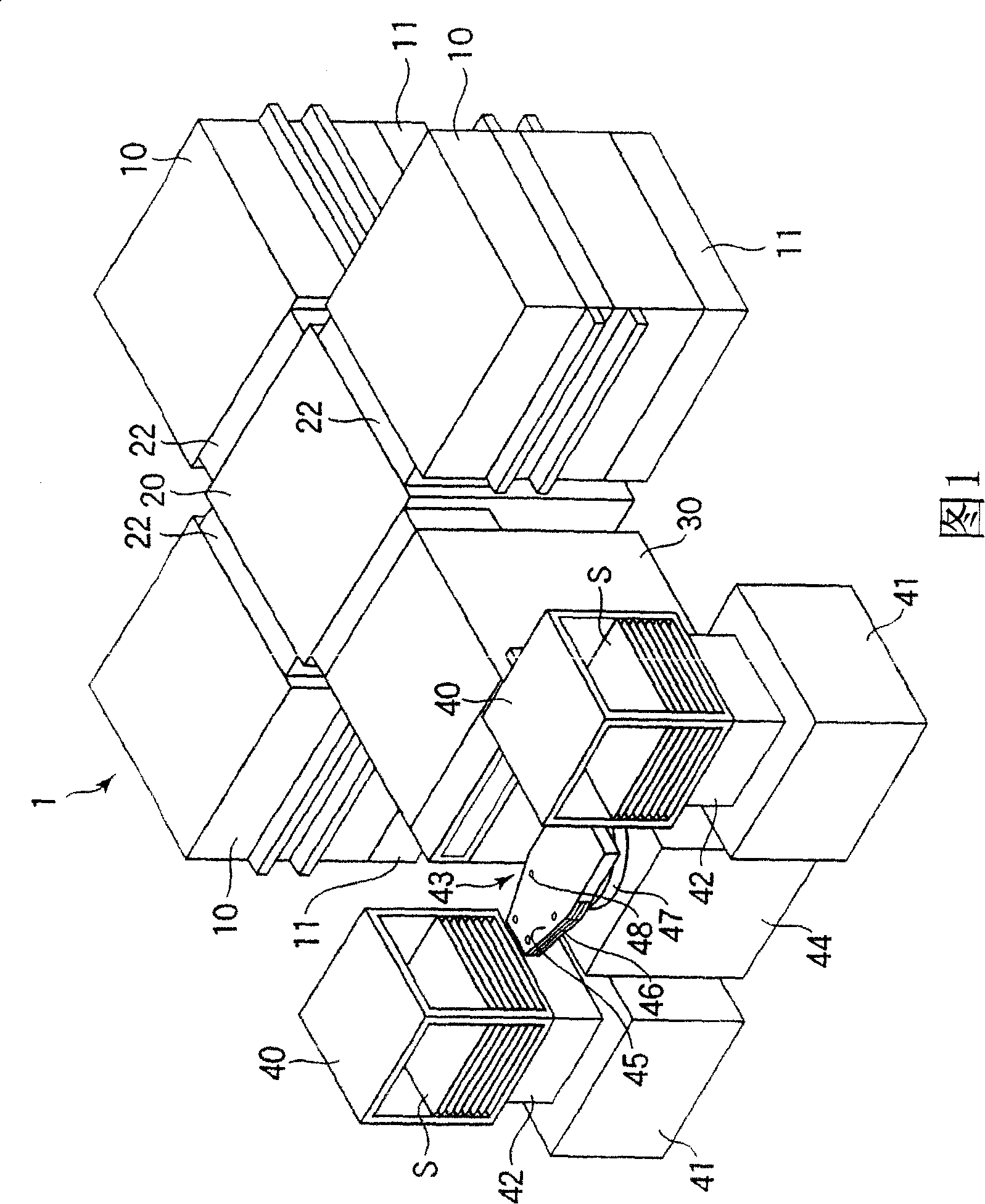

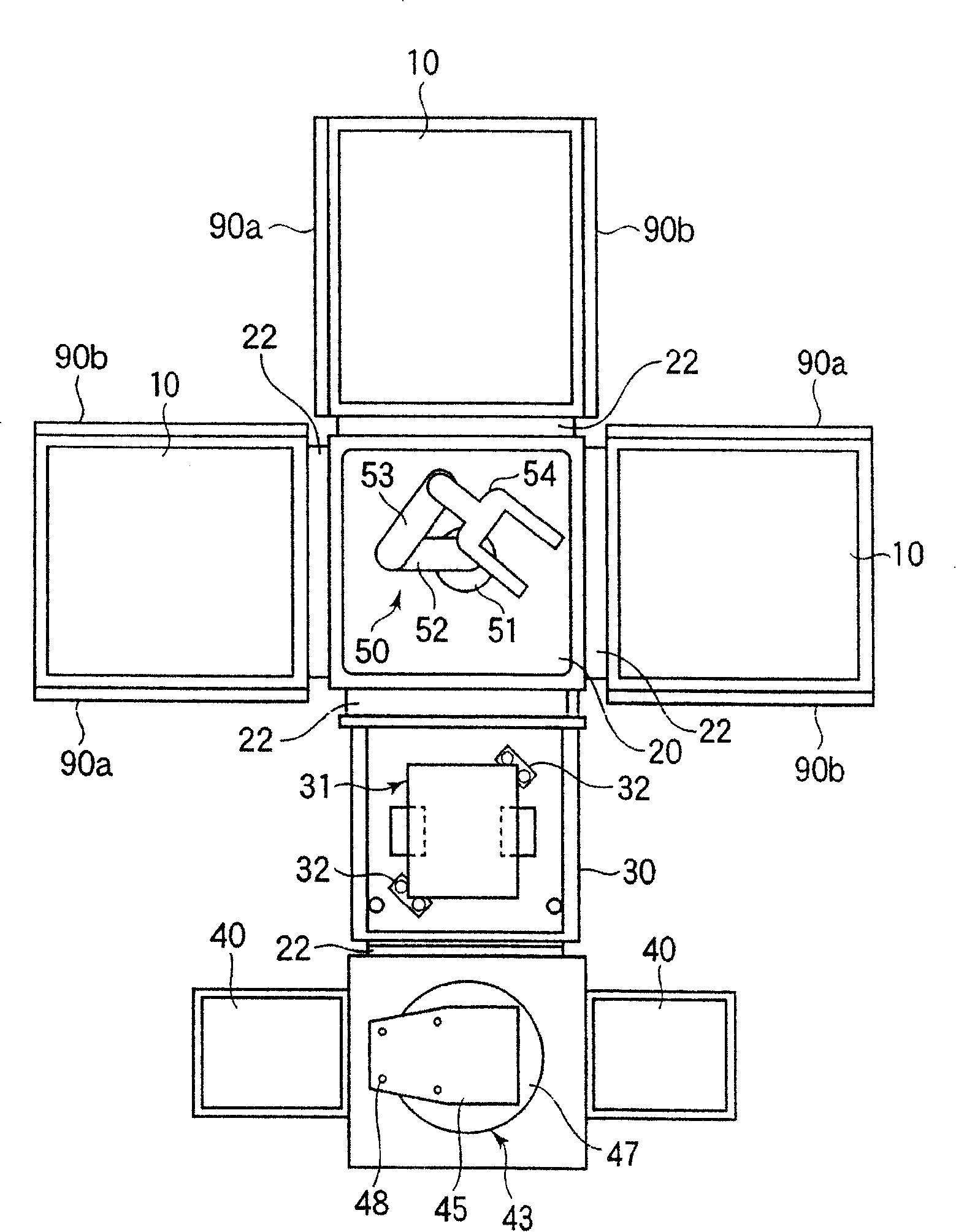

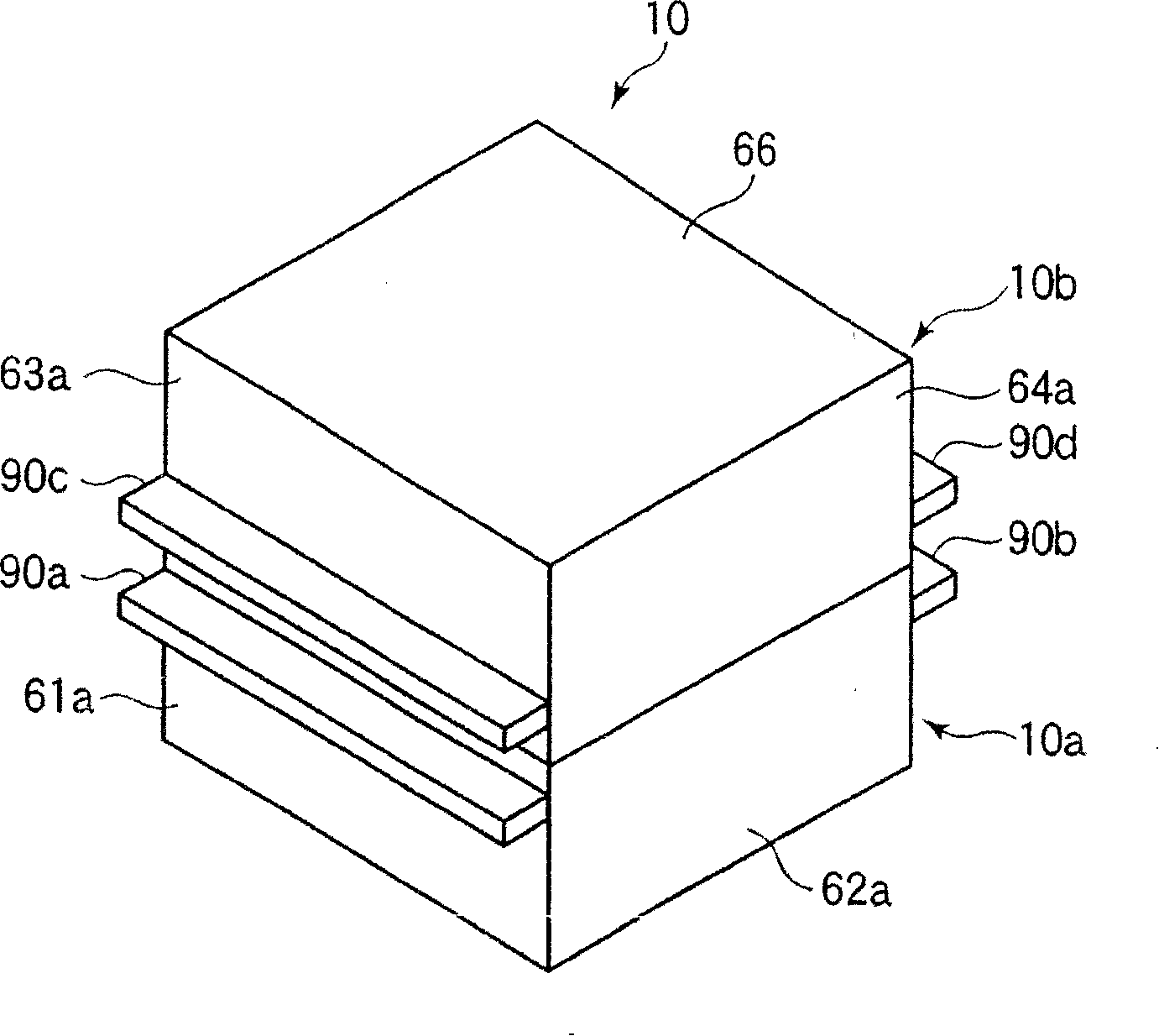

[0039] FIG. 1 is a perspective view showing a rough outline of the vacuum processing system, figure 2 is a horizontal sectional view showing its interior. Additionally, in Figure 1 and figure 2 , details are omitted from the illustration.

[0040] In this vacuum processing system 1 , a transfer chamber 20 and a load lock chamber 30 are provided in a continuous manner at the center thereof. Around the transfer chamber 20, three vacuum chambers 10 are arranged. Each vacuum chamber 10 is placed on a support table 11 . Between the transfer chamber 20 and the load lock chamber 30, between the transfer chamber 20 and each vacuum chamber 10, and at the opening where the load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com