Kitchen waste pretreatment device

A pretreatment device and a technology of food waste, which are applied in the direction of recycling fat oil/fatty acid from waste, filtration circuit, filtration separation, etc., can solve the problems of not found, reduce the cost burden, shorten the fermentation cycle, and exempt garbage disposal fees Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

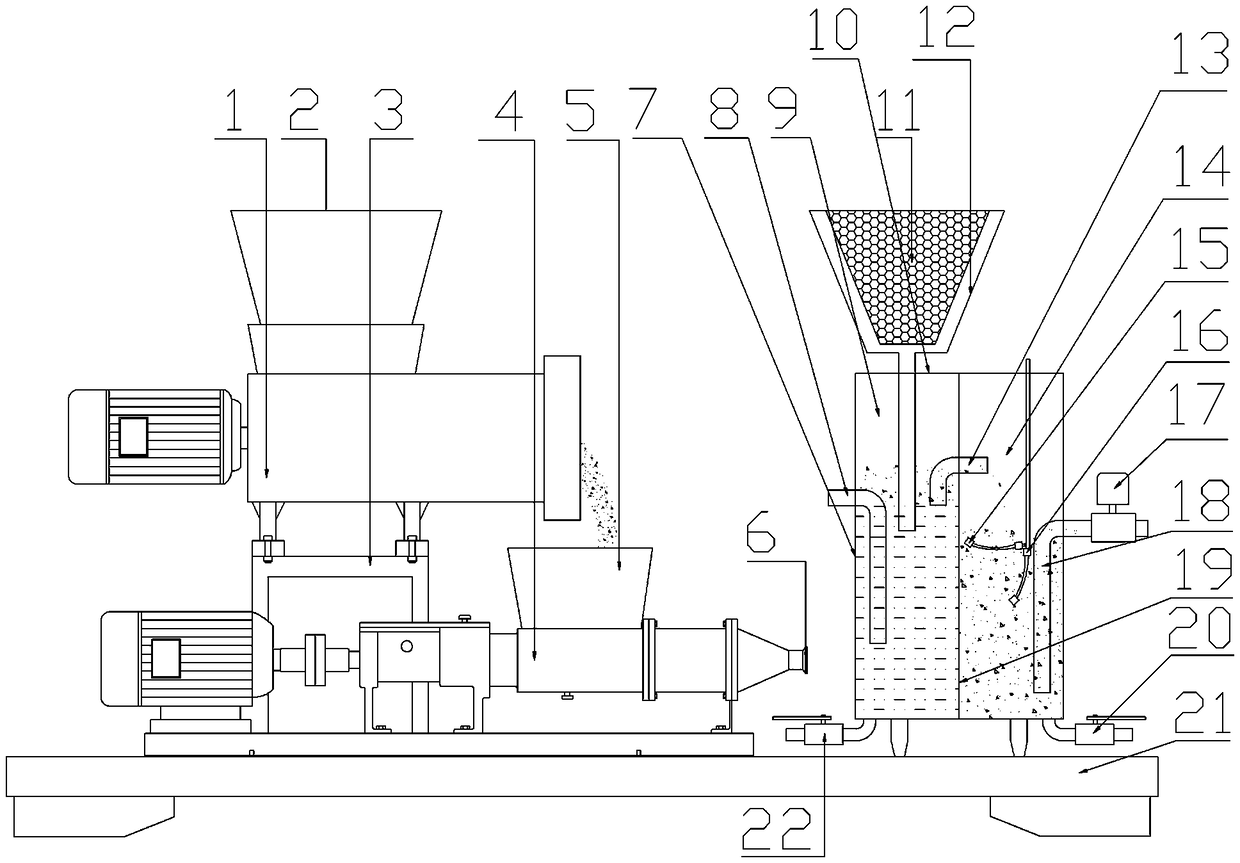

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 As shown, the food waste pretreatment device of the present invention includes two parts: a crushing device and an oil-water separation device, wherein the crushing device includes a crushing machine 1, a food waste inlet 2, a frame 3, and a screw conveying pump 4 , Screw conveyor pump feed inlet 5, screw conveyor pump outlet 6. The pulverizer is installed and fixed on the frame 3, the food waste feeding port is connected with the pulverizer, the frame 3 is mounted and fixed on the base 21, the screw delivery pump 4 is installed on the base 21, and the screw delivery pump The feed inlet directly receives the output material of the pulverizer, and the outlet of the screw conveying pump is connected with the subsequent equipment. The oil-water separation device 7 includes an oil-water separation device housing 10, a sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com