Cooling device for high power laser metal pumping cavity

A technology of a cooling device and a pump cavity, applied in laser technology and its application fields, can solve the problems of high difficulty in machining, complicated mechanical assembly, reduced output power, beam quality, etc., and achieves low machining difficulty, improved stability, The effect of high sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

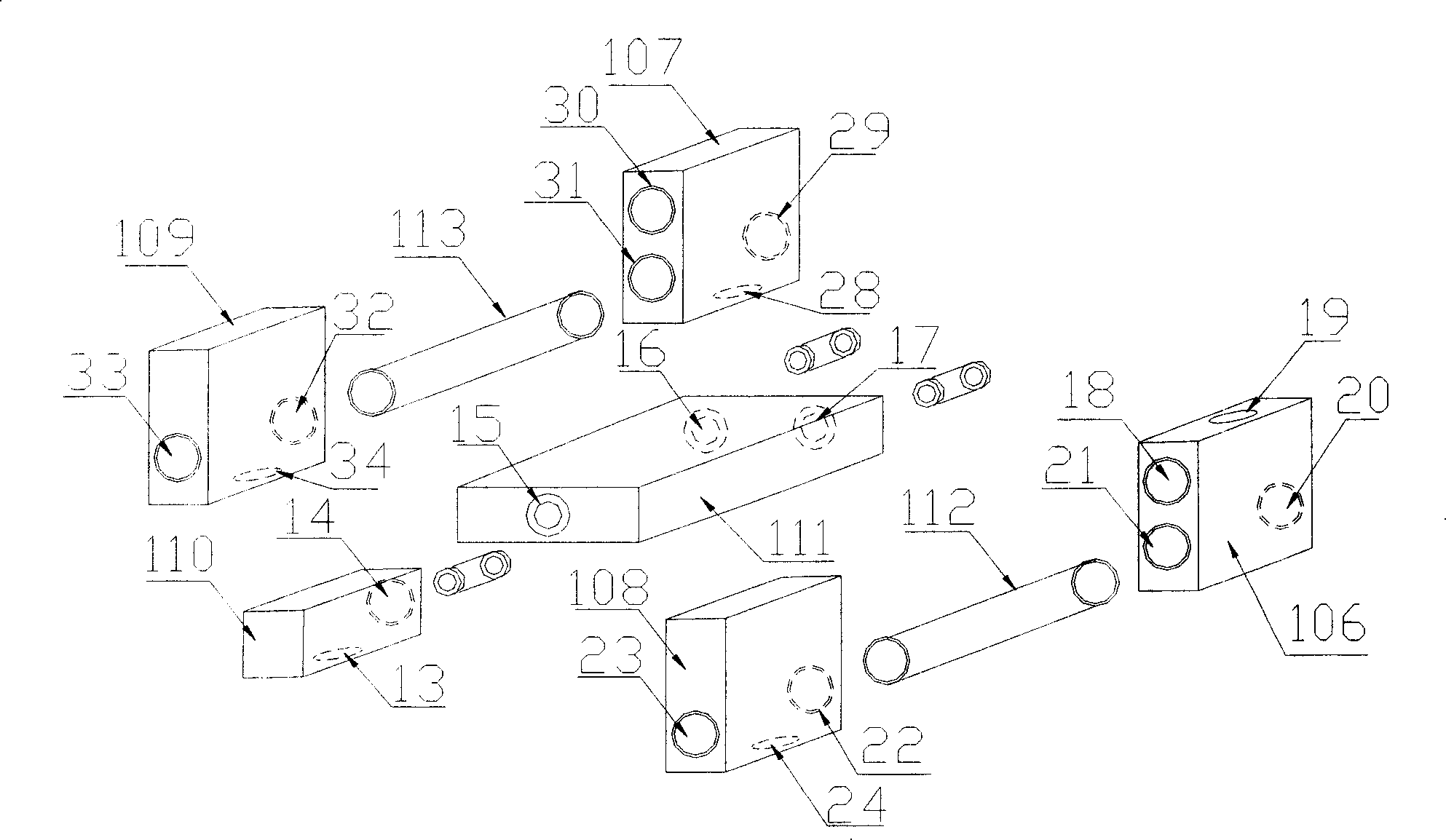

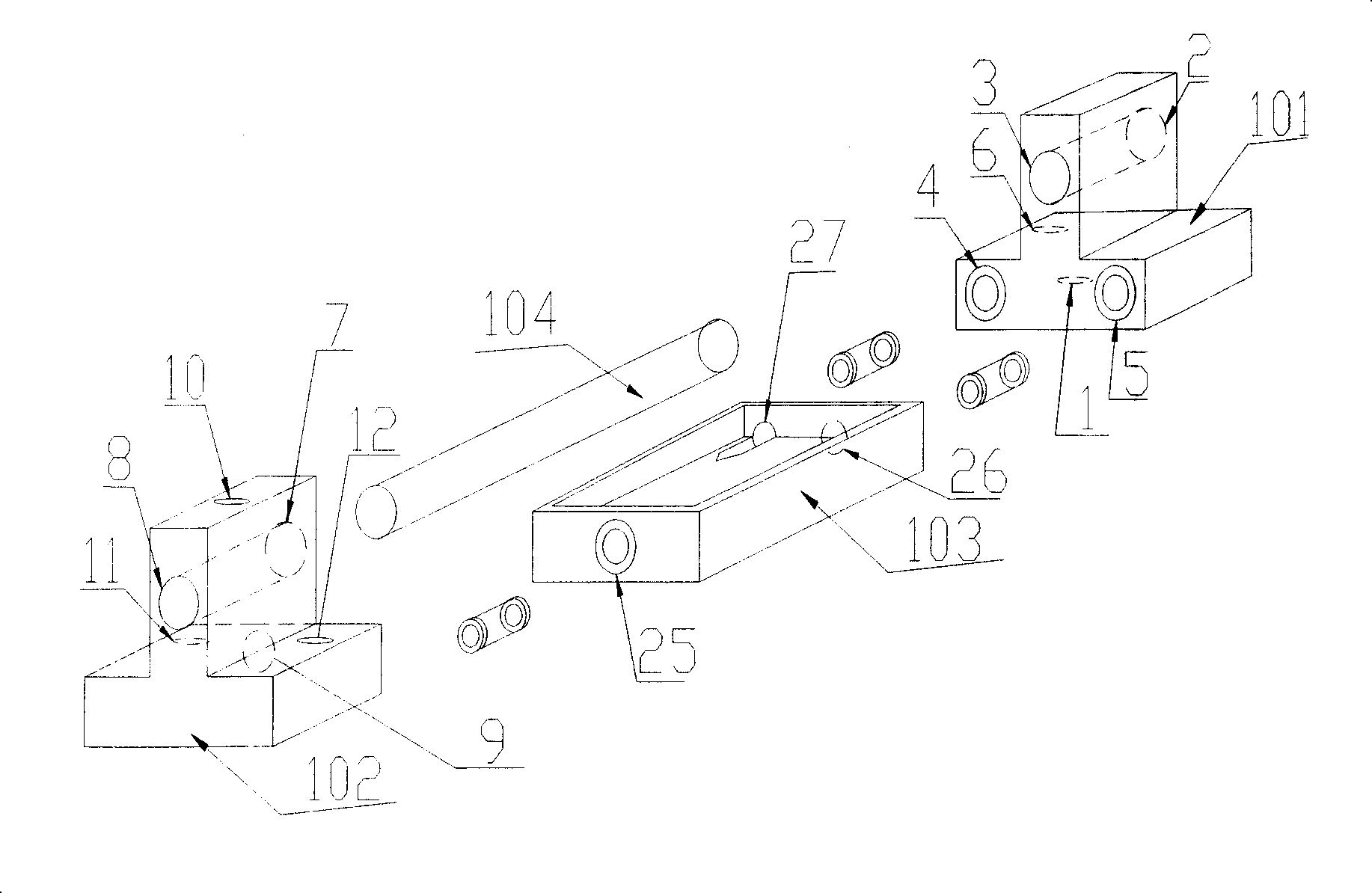

[0036] Attached below Figure 1 to Figure 25 This embodiment will be described.

[0037] The present invention adopts the following technical solutions. In this method, according to the amount of heat absorbed by the working substance, the reflecting surface, and the pump lamp, it is determined that the cooling water first concentrates on cooling the working substance. The cooling water flowing out of the reflecting surface cools the two pump lamps respectively, and finally flows out of the cooling system.

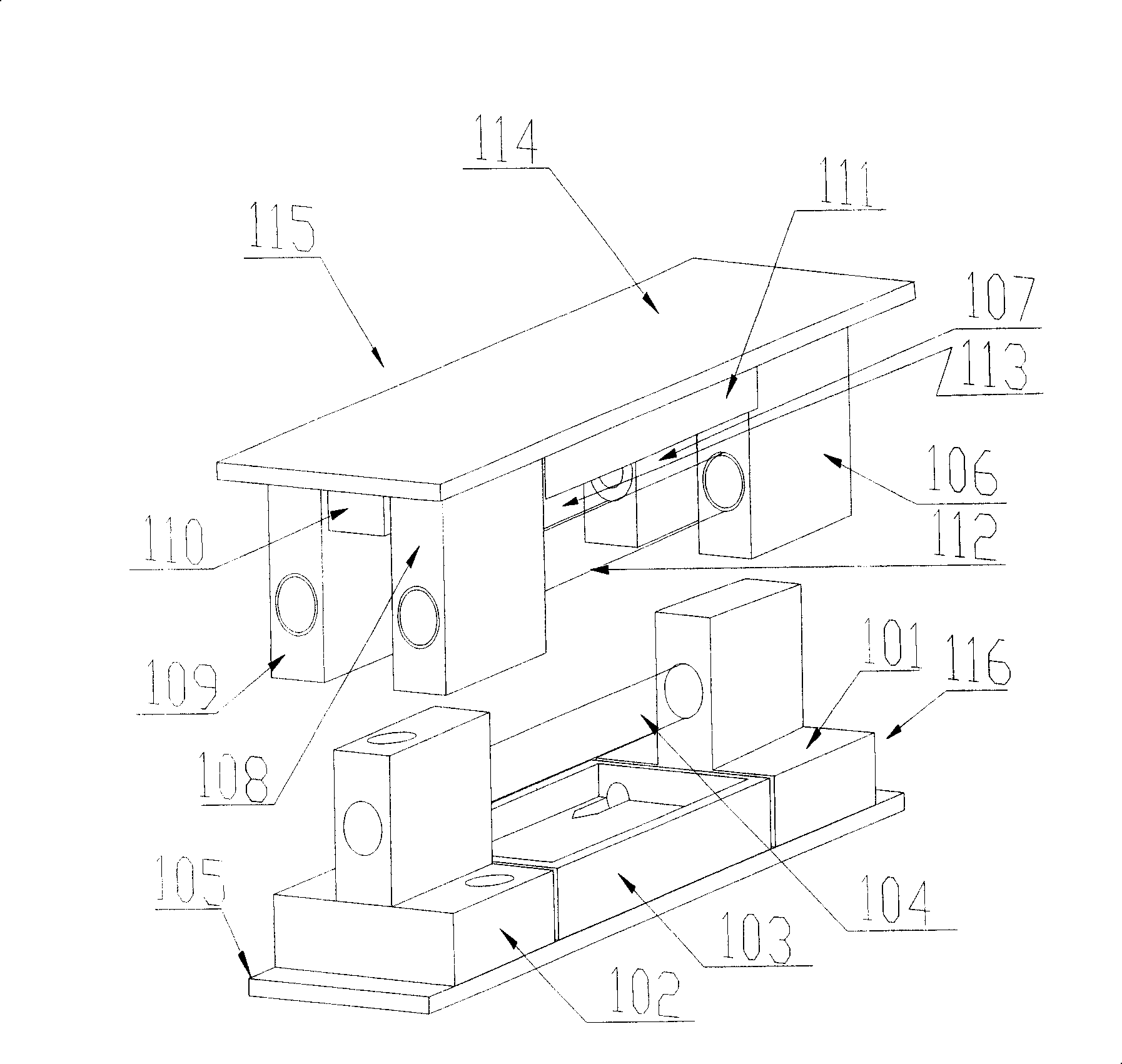

[0038] According to the cooling method of high-power solid-state lasers, a set of device transfer blocks and connection block graphics in the cooling cavity is designed. The general structure diagram is as follows figure 1 . The device is aimed at pumping a single working substance with two lamps. This device mainly includes two pump chamber lower body 116 and pump chamber upper body 115 which are similar in structure and can be connected with each other. The pump cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com