A control method for an engine endoscope cooling control device

A control method and cooling control technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve problems such as high price, economic loss, lens damage, etc., to ensure safe and reliable operation, and avoid internal peeping Mirror burnout and reduce economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred examples.

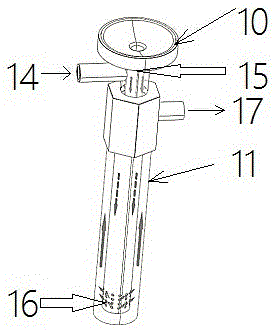

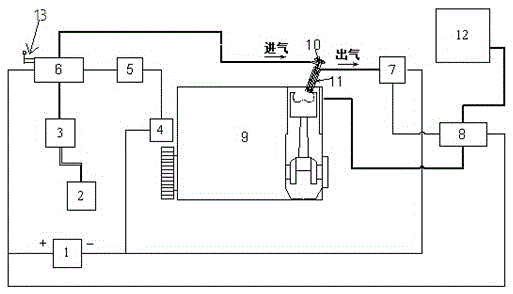

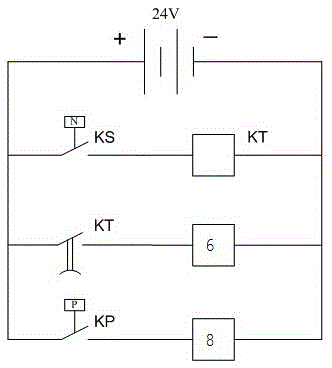

[0027] as attached figure 1 and 2 As shown, the preferred embodiment of the present invention mainly includes power supply 1, cooling air source 2, air pressure regulating valve 3, JMP electronic speed relay 4, delay relay 5, air solenoid valve 6, pressure relay 7, fuel solenoid valve 8, Engine 9, endoscope 10 installed on the engine cylinder head, protective sleeve 11, fuel tank 12, manual switch 13, cooling air inlet 14, fiber optic bundle top 15, fiber optic bundle bottom air outlet 16, cooling air outlet 17 . The endoscope 10 is placed in the protective sleeve 11, the top end 15 of the fiber bundle of the endoscope is connected to the cooling air inlet 14, the endoscope is provided with an air outlet 16 at the bottom end of the fiber bundle, and the cooling air passes through The air outlet 16 at the bottom end of the endoscope f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com