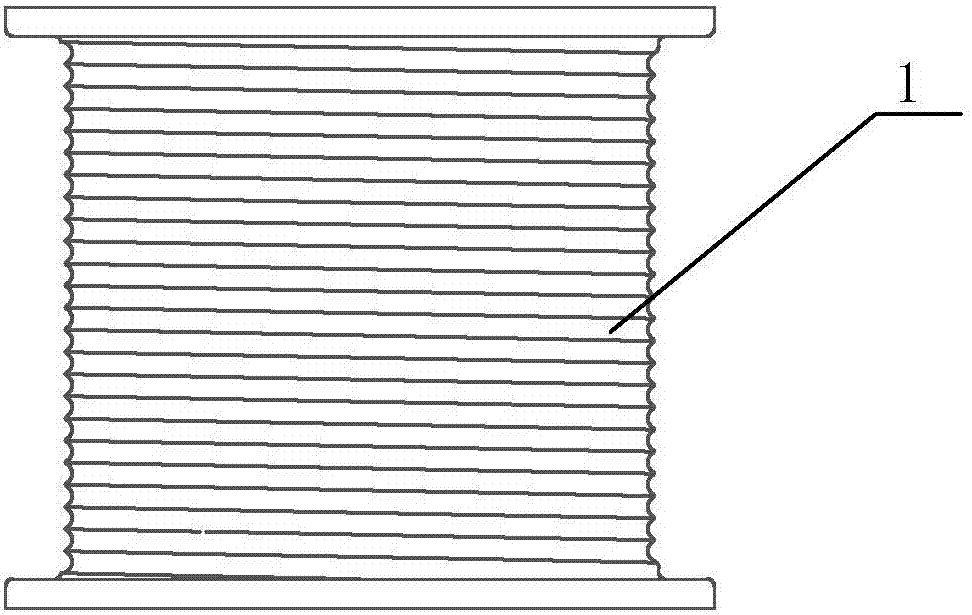

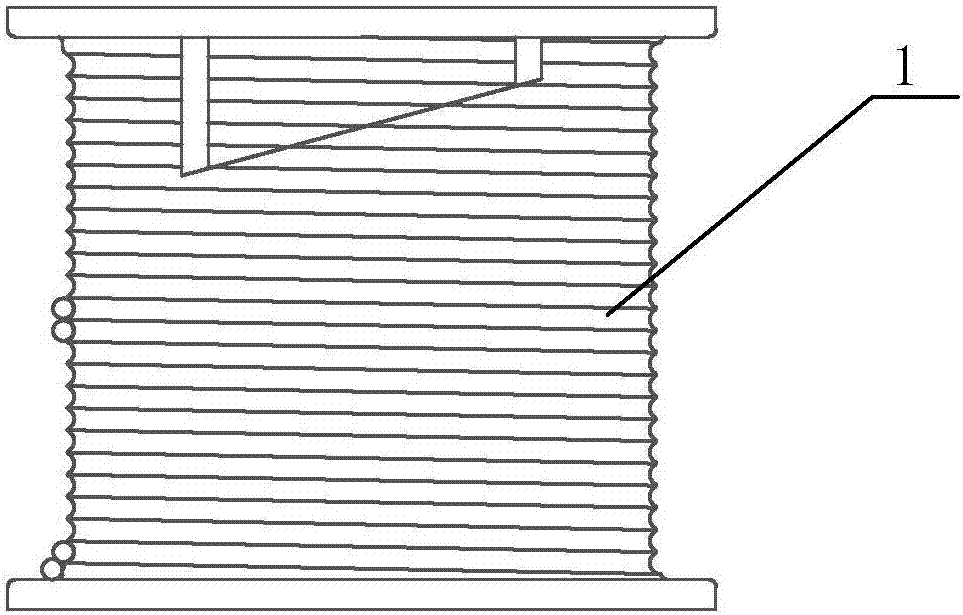

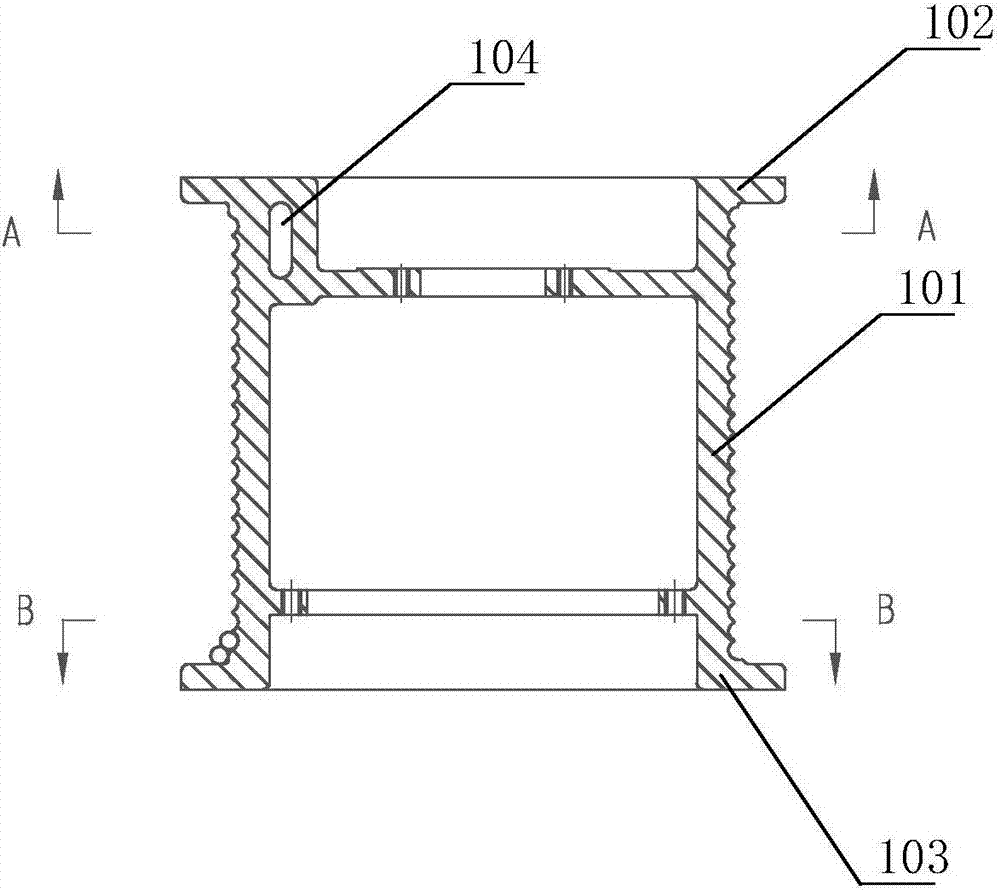

A high-strength and high-abrasion-resistance cast steel reel and its preparation method

A high-wear-resistance, high-strength technology, used in casting and forming equipment, molds, mold components, etc., can solve the problems of unsatisfactory comprehensive mechanical properties of cast steel reels, unable to meet engineering needs, and reduce production. Efficiency, cost saving, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0049] The invention provides a cast steel reel with high strength and high wear resistance, which is processed by cast steel materials, and the cast steel used includes the following components in weight percentage: 0.60% to 0.85% of C; 6.0% to 8.0% 0.8% to 1.2% of Si; 4.5% to 5.5% of Cr; 0.8% to 1.2% of Mo; 0.3% to 0.5% of Cu; 1.0% to 1.2% of Ni; 0.15% to 0.25% of Ti 0.20% to 0.40% of V; 0.030% to 0.040% of RE; 0.020% to 0.030% of Mg; S<0.02%; P<0.03%; the balance is Fe and unavoidable impurities.

[0050] In one embodiment of the present invention, the weight percentage of Mo is 0.9%-1.1%.

[0051] In one embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com