Fuel injection valve for internal combustion engines

一种燃料喷射阀、内燃机的技术,应用在燃料喷射装置、装料系统、机械设备等方向,能够解决最佳喷射不再得到保证等问题,达到可靠压力卸载的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

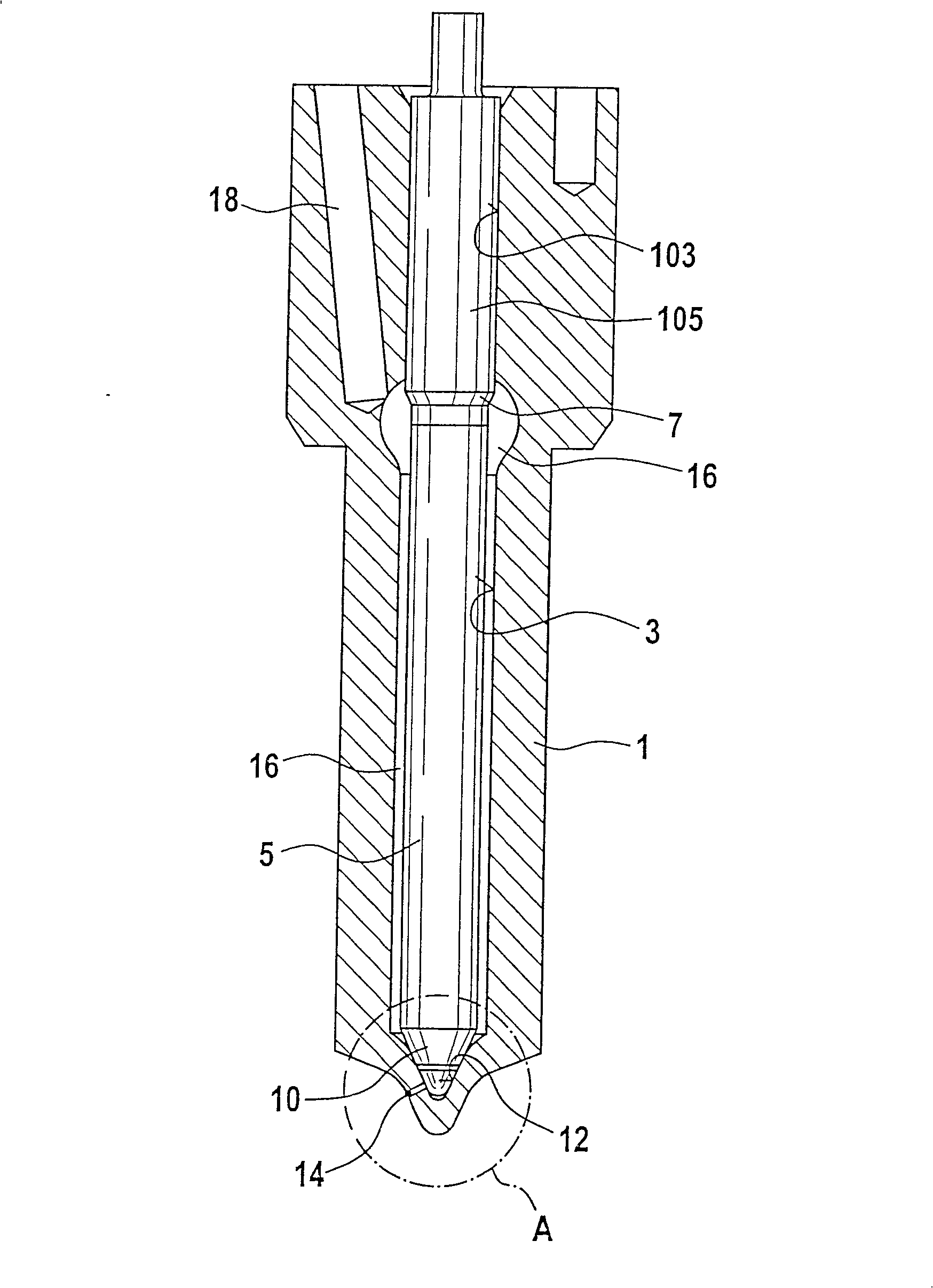

[0044] figure 1 A fuel injector according to the invention is shown in longitudinal section. A bore 3 is formed in the valve body 1 , which is delimited at its combustion chamber-side end by a conical valve seat 12 . At least one injection opening 14 leads from the valve seat 12 , which opens into the combustion chamber of the internal combustion engine in the installed position of the fuel injection valve. A piston-like valve needle 5 is arranged longitudinally displaceably in the bore 3 , which valve needle is guided by a guided section 105 in the guide section 103 of the bore 3 . Starting from the guided section 105 of the valve needle 5 , the valve needle 5 shrinks toward the valve seat 12 forming the pressure shoulder 7 and transitions into a valve sealing surface 10 at its combustion chamber-side end. In its closed position, the valve needle 5 bears against the valve seat 12 with the valve sealing surface 10, so that the nozzle opening 14 is closed with respect to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com