Coal gas generation and combustion device for heating sand and gravel in asphalt mixing station

A technology of combustion device and gas generator, which is applied to roads, road repairs, roads, etc., can solve the problems of complex work sites, many personnel and equipment, and high environmental safety requirements, and achieve convenient control, ensure non-stop production, and ensure output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings.

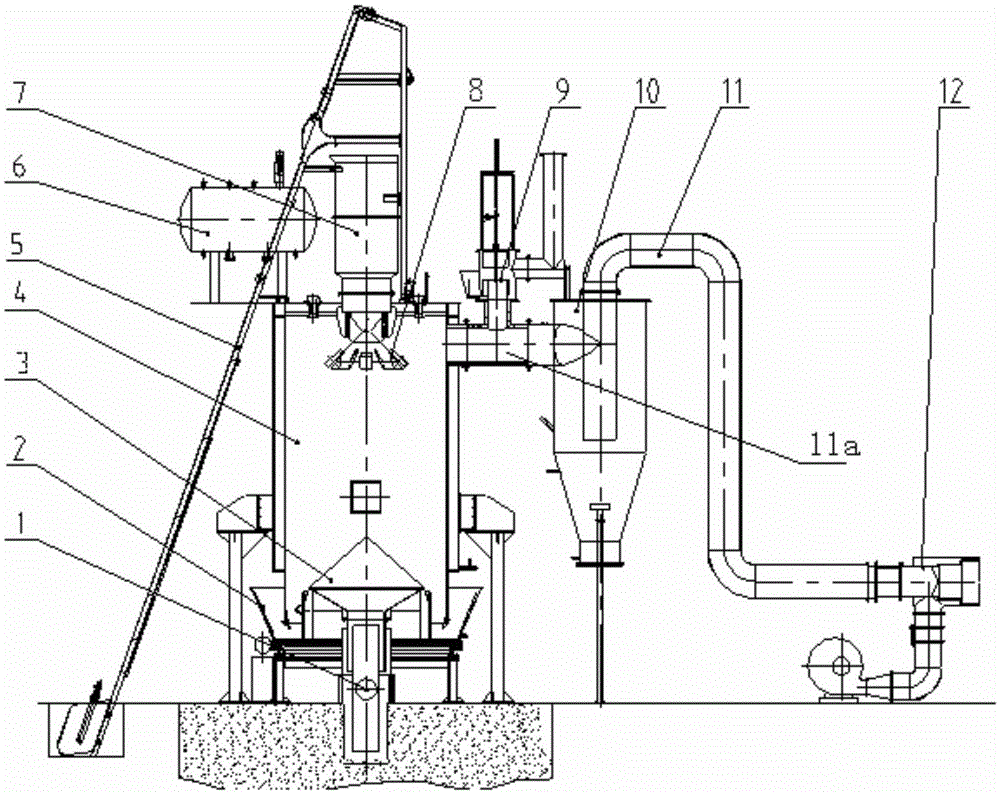

[0079] As an example of the present invention, the coal gas generation and combustion device used for heating sand and gravel materials in an asphalt mixing station is described below, and the device includes:

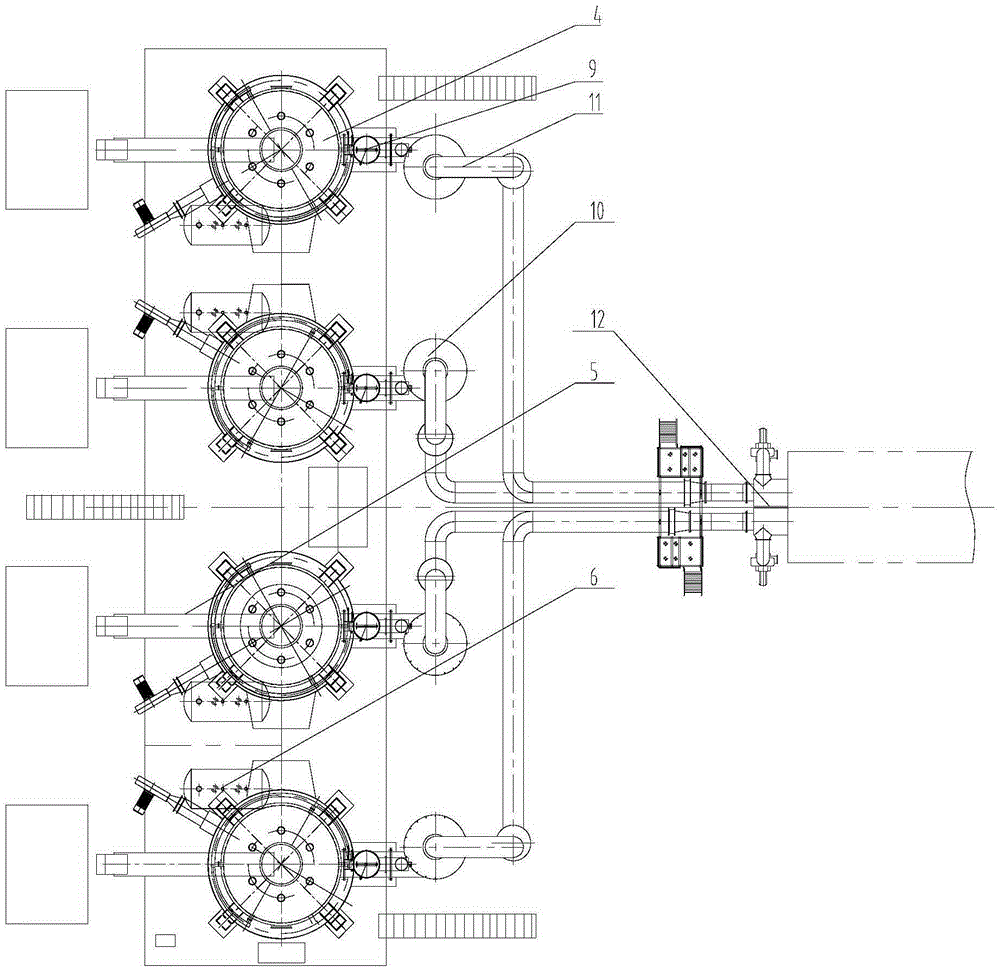

[0080] n gasifiers 4 arranged in parallel,

[0081] n dust collectors 10 respectively corresponding to or matched with each gas generator 4,

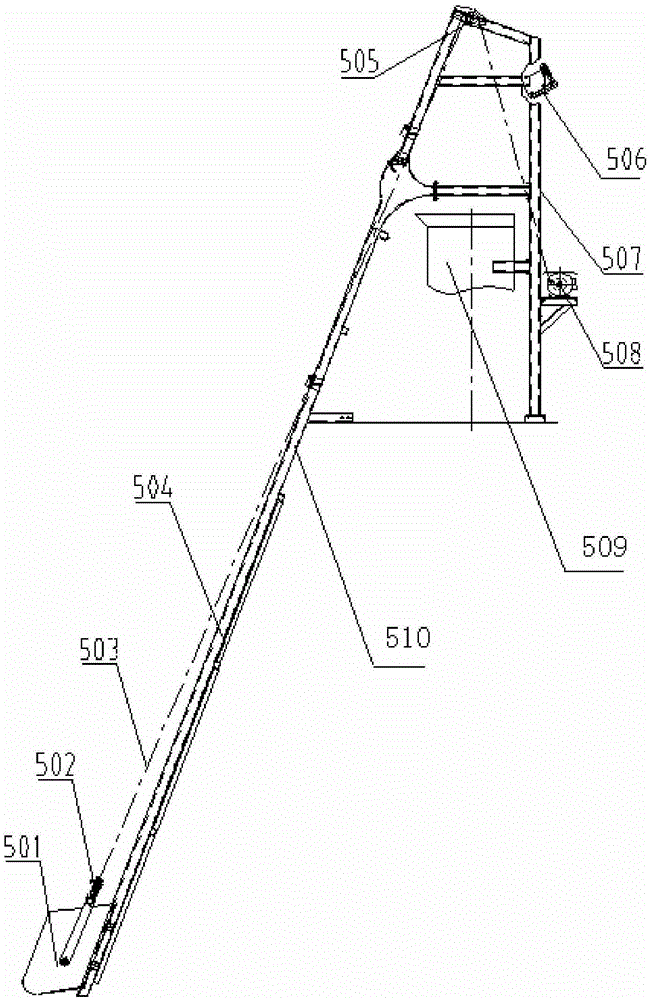

[0082]The charging mechanism 5 that is arranged on each gasifier 4, and

[0083] n combustion devices 12 respectively corresponding to or matched with each gas generator 4,

[0084] Here, n is an integer of 2-7, preferably an integer of 3-6, more preferably 3 or 4 or 5,

[0085] There is a gas outlet on the top of each gas generator and the gas outlet is connected to the air inlet of each corresponding dust collector 10 via the corresponding gas tee pipe 11a, and the gas outlet of each dust collector 10 is output thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com