Melt rotating fast filter for extruder

A rotary filter and extruder technology, applied in the field of extruder melt filter, can solve the problems of large pressure fluctuation, large change, and small screen filter area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

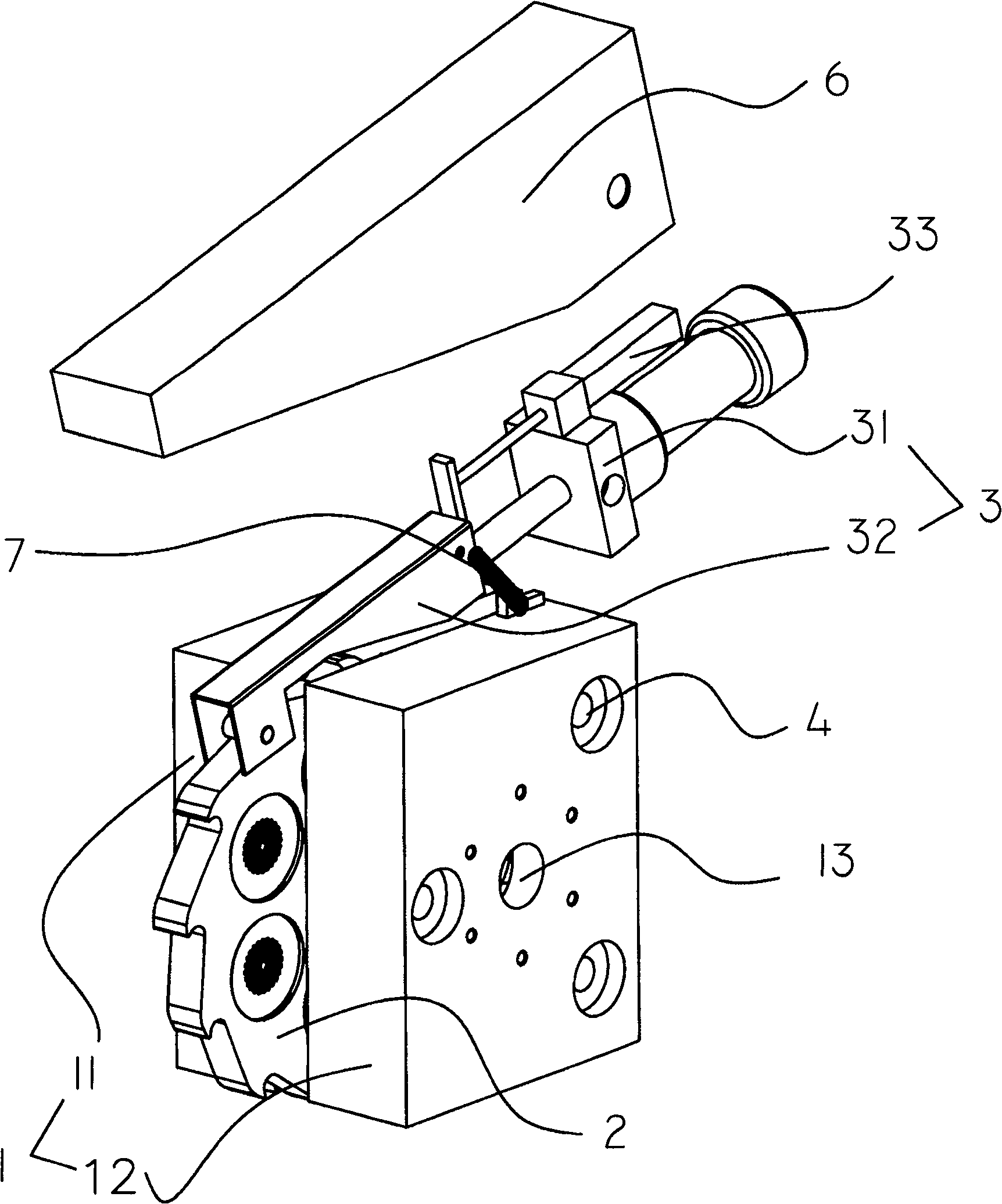

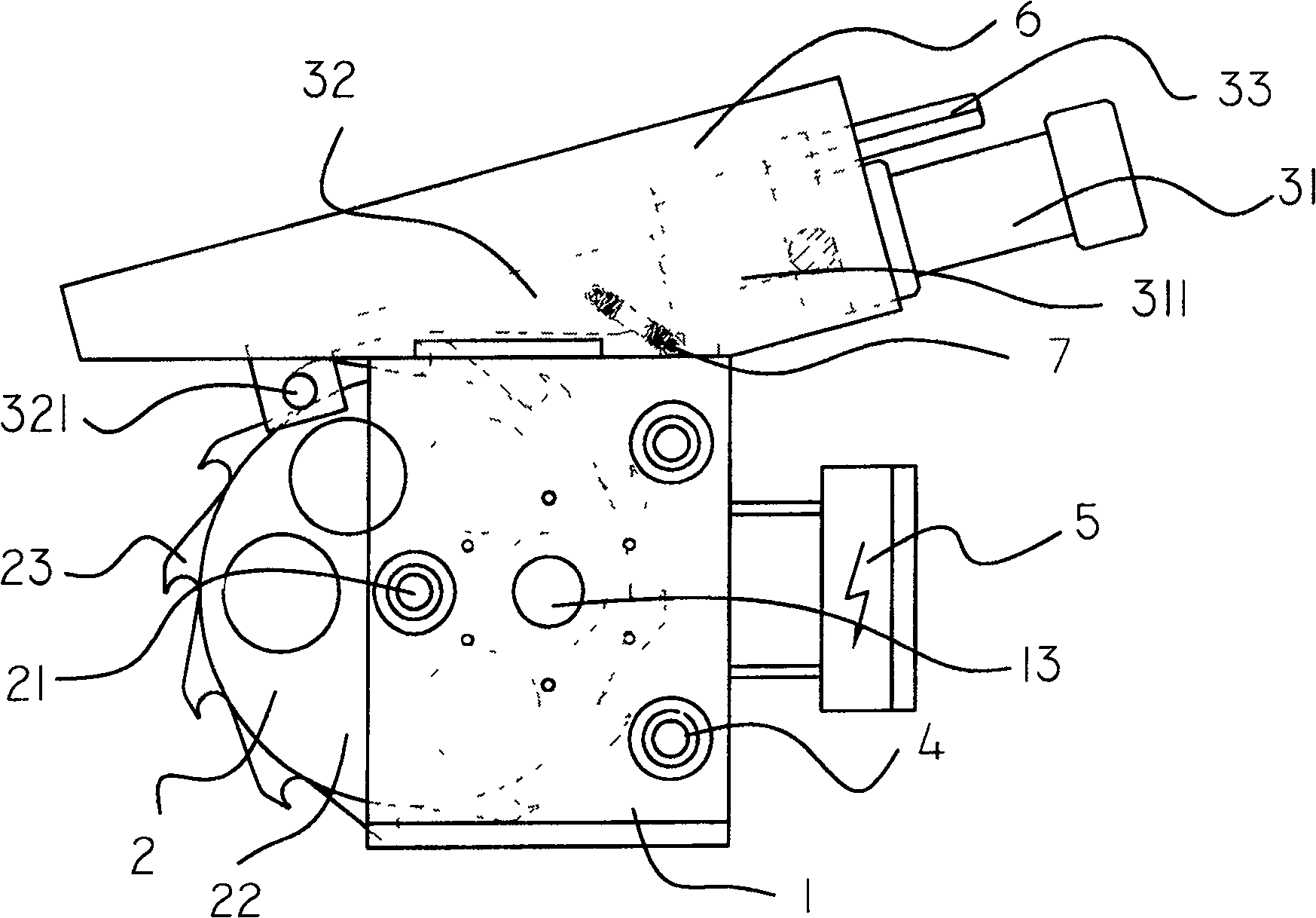

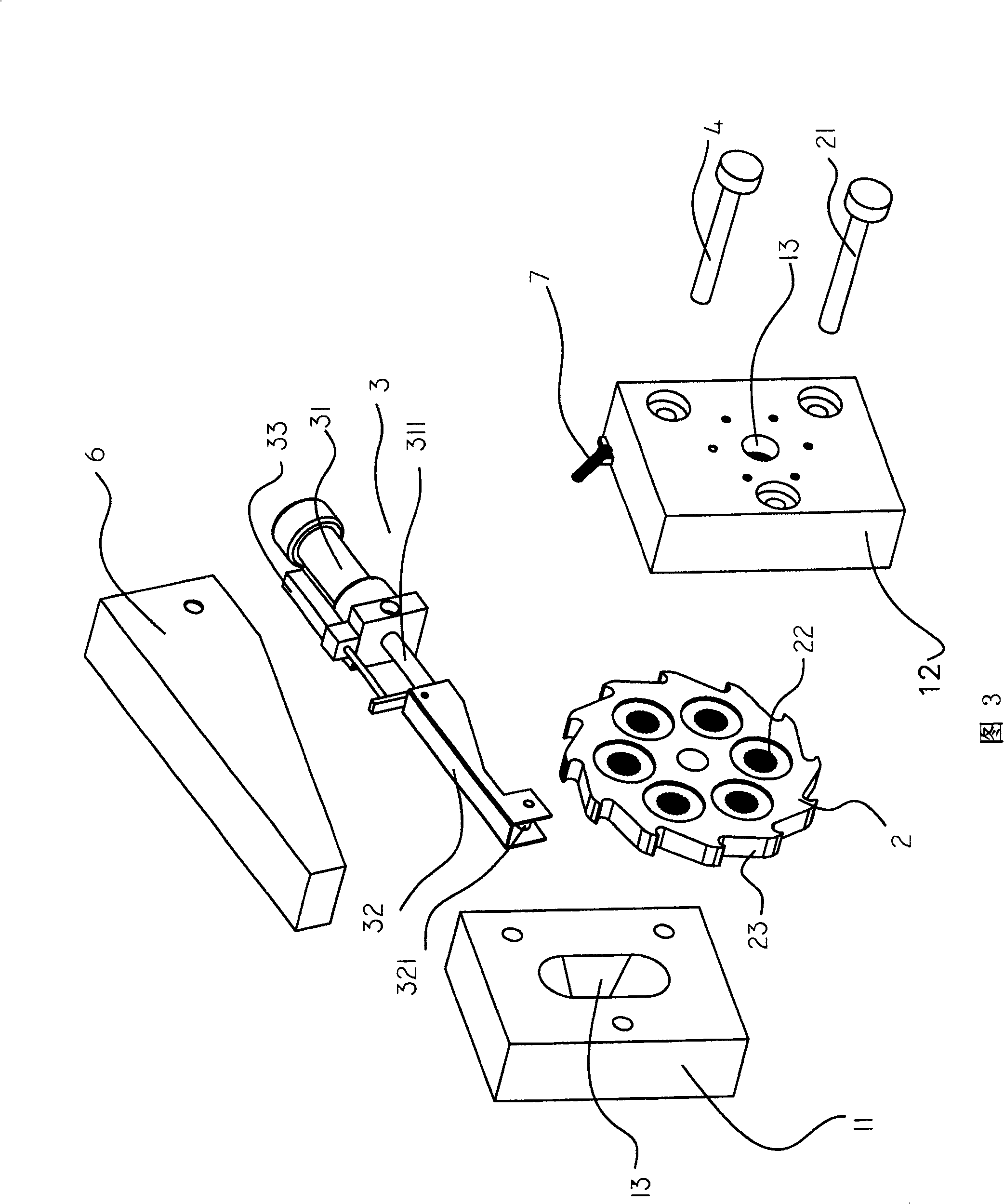

[0012] Such as figure 1 , 2 As shown in and 3, an extruder melt rotary filter is composed of a mold body 1, a filter screen plate 2 and a hydraulic assembly 3, and the mold body 1 is a split type, including a feed mold body 11 and a discharge mold body 12. The two are fixedly connected by screws 4. The front and rear of the mold body 1 are provided with through flow passage holes 13. The mold body 1 has a built-in heating rod (not shown in the figure), and a junction box 5 is placed outside.

[0013] The filter screen plate 2 is a ratchet type filter screen plate, which is fixed between the feed mold body 11 and the discharge mold body 12 with a rotating shaft 21, and a plurality of filter mesh holes 22 are arranged on it, and the mesh holes 22 are provided with Filter screen; the filter screen holes 22 are evenly distributed around the center of the ratchet wheel. Here, the size of the flow channel through hole 13 can cover two or more filter meshes 22. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com