Cooling system for cold and hot water machine set with fan disc pipe

A technology for cold and hot water units and fan coil units, which is applied in the field of control systems, can solve the problems of the host requiring special personnel management, energy waste, inconvenient use, etc., and achieves the effects of overcoming no-load work, avoiding waste, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

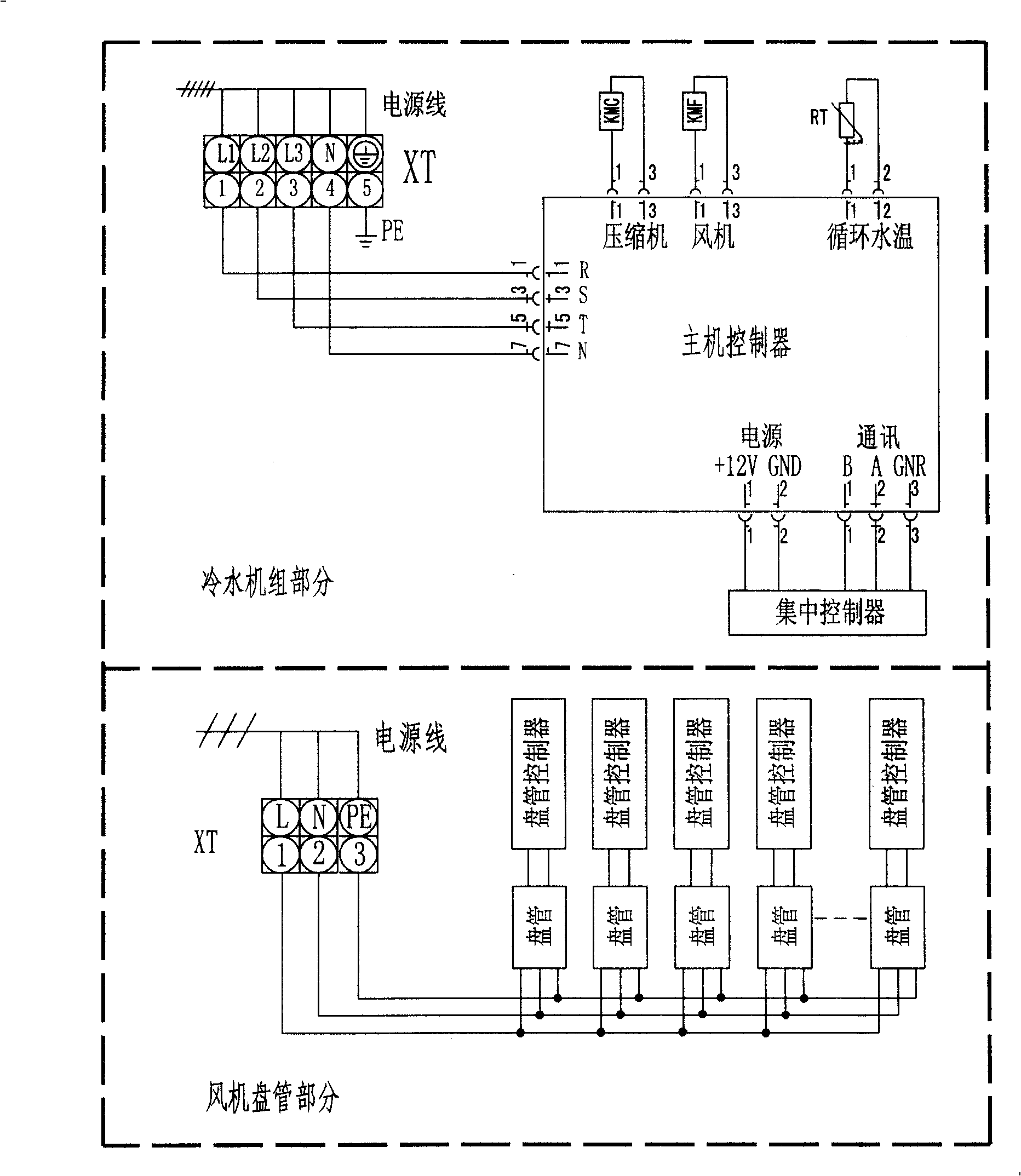

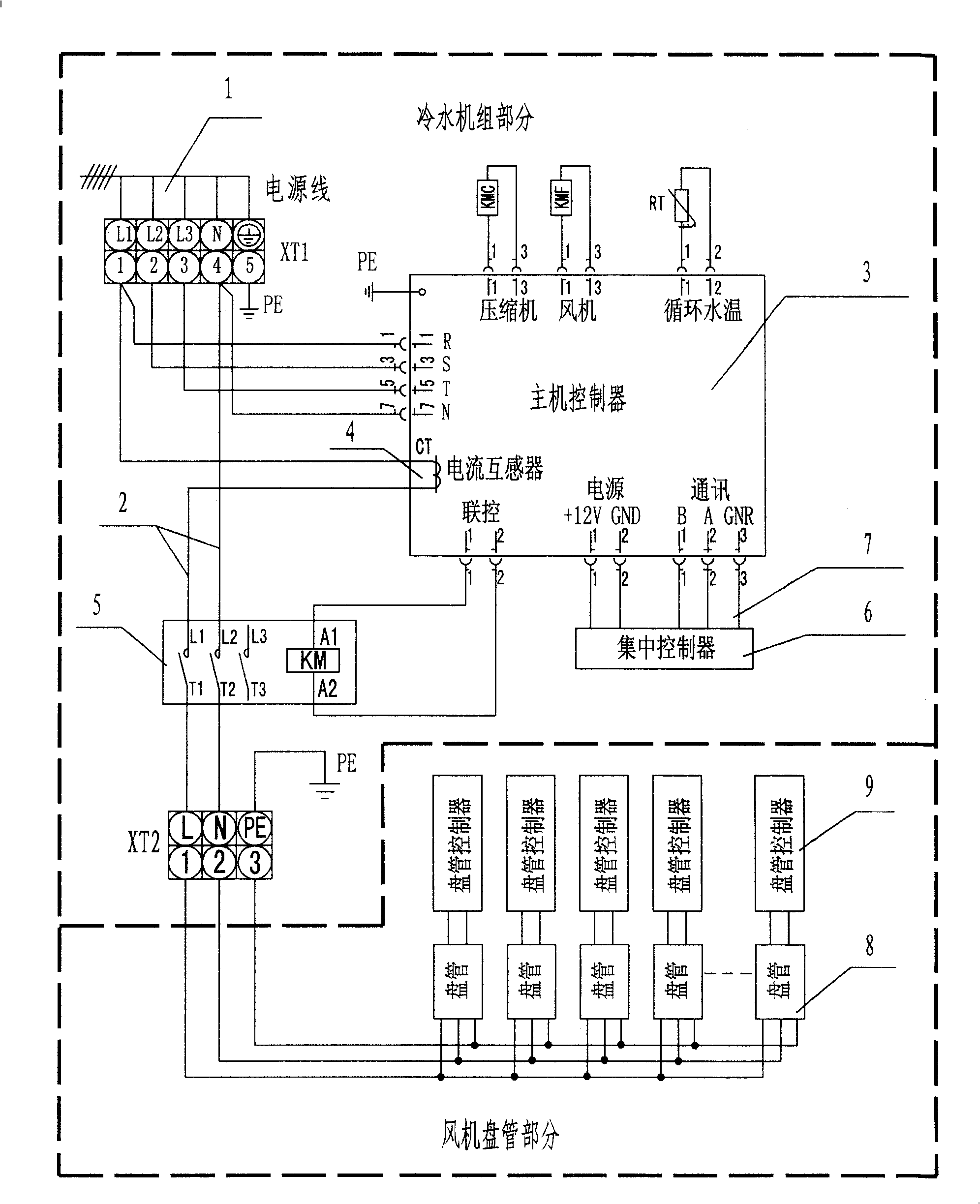

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 2 As shown, the cold and hot water unit control system with fan coil unit of the present invention consists of a power cord 1, a power connection cord 2, a host controller 3, a current transformer 4, an AC contactor 5, a centralized controller 6, and a communication line 7. Composed of fan coil unit 8 and coil unit controller 9. The motor power of the fan coil unit 8 is provided by the AC contactor 5, and the AC contactor 5 is controlled by the host controller 3, and the host controller 3 is provided with a current transformer 4 and a current detection circuit for detecting the power supply current of the fan coil unit 8 , by detecting and judging the current of the fan coil unit 9, the host controller 3 and the coil controller 9 respectively perform interlocking control on the motor power supply of the fan coil unit 8, the host unit and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com