Engineering machine

A technology of construction machinery and stroke, which is applied in the direction of motor vehicles, earthmoving machines/shovels, construction, etc., can solve the problems of low operation efficiency, low operation efficiency, rising manufacturing cost, etc., to improve operation efficiency, prevent damage, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

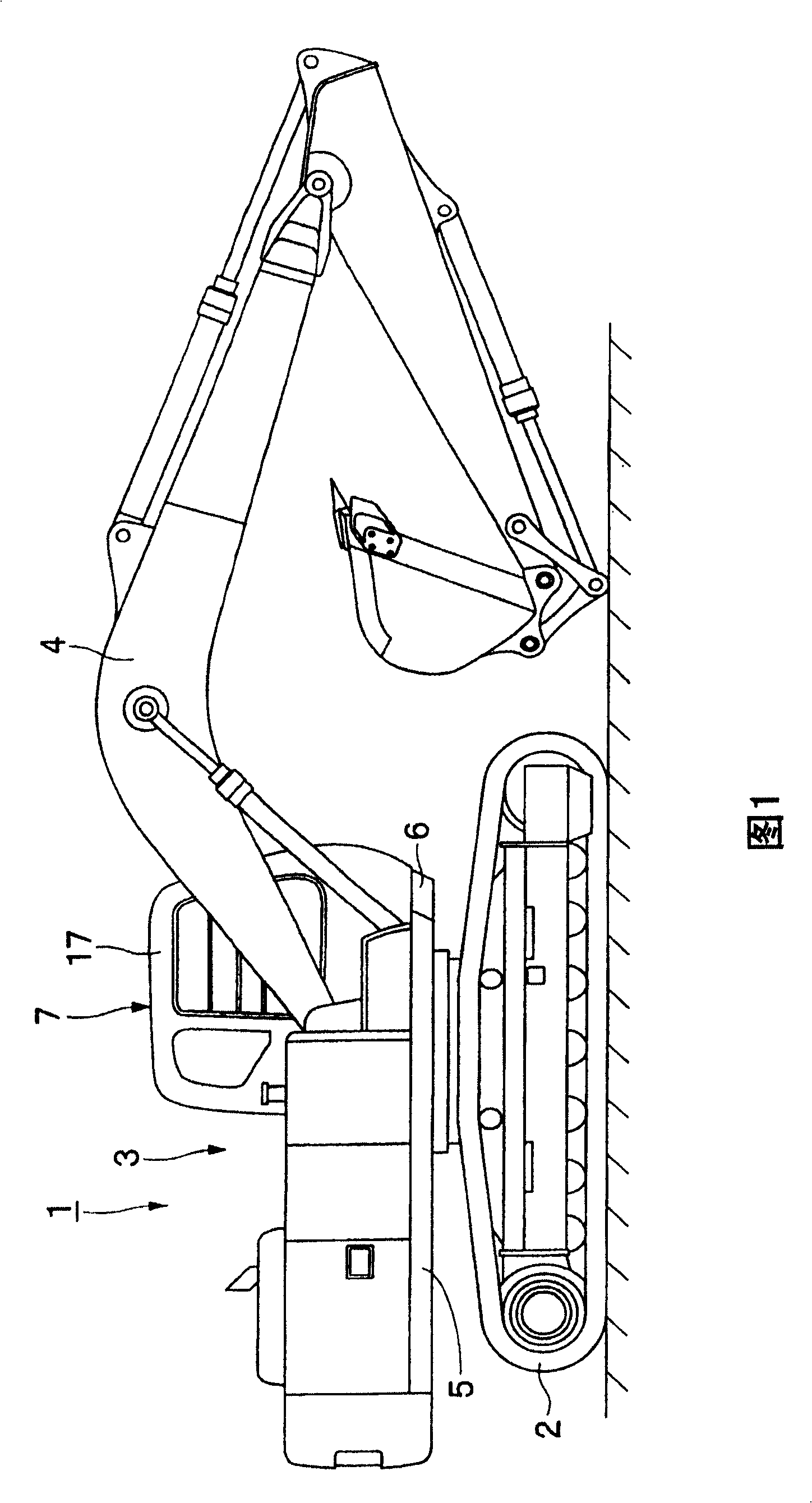

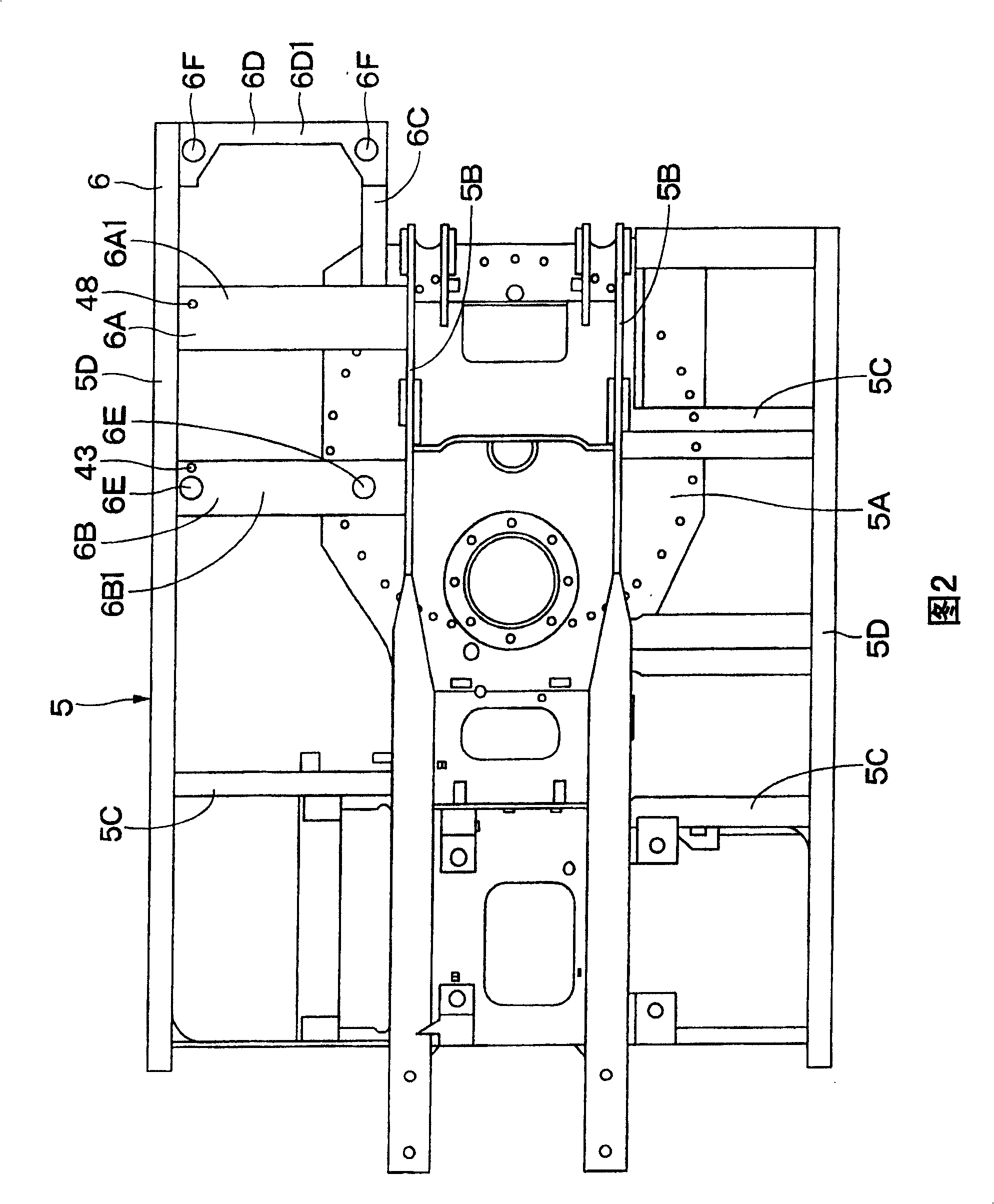

[0054] Hereinafter, as a construction machine according to an embodiment of the present invention, a crawler-type hydraulic excavator is taken as an example, with reference to FIGS. Figure 14 to explain in detail.

[0055] In FIG. 1 , 1 is a crawler-type hydraulic excavator as a construction machine. This hydraulic excavator 1 is roughly composed of a lower traveling body 2 that can freely walk, and an upper revolving body 3 that is rotatably mounted on the lower traveling body 2 . , It is configured as a working device that can be installed on the front side of the upper rotating body 3 in a vertically tilted manner to perform excavation work of earth and sand.

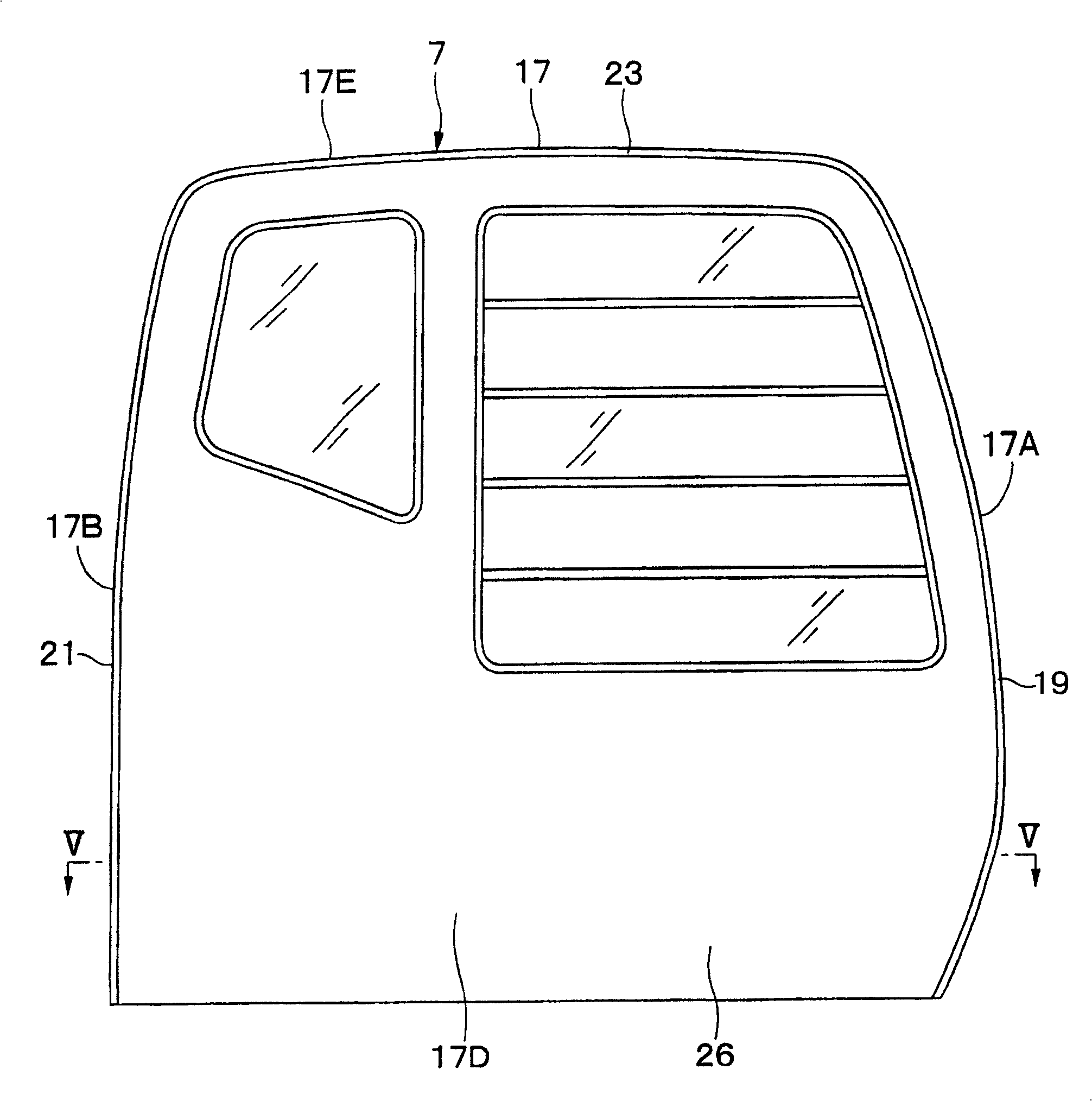

[0056] In addition, the upper revolving body 3 includes: a revolving frame 5 described later that is rotatably provided on the undercarriage 2 ; The vibration-absorbing state of the cab 7 is supported by an anti-vibration seat 41 described later and overturn regulation devices 42 and 47 for suppressing a large disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com