Organicelectroluminescent device and its preparation method

An electroluminescent device, organic technology, applied in the direction of electroluminescent light source, electric solid-state device, semiconductor/solid-state device manufacturing, etc., can solve the problems of large doping concentration error of the light-emitting layer, unstable device performance, and can no longer be adjusted. , to achieve the effect of good stability and luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

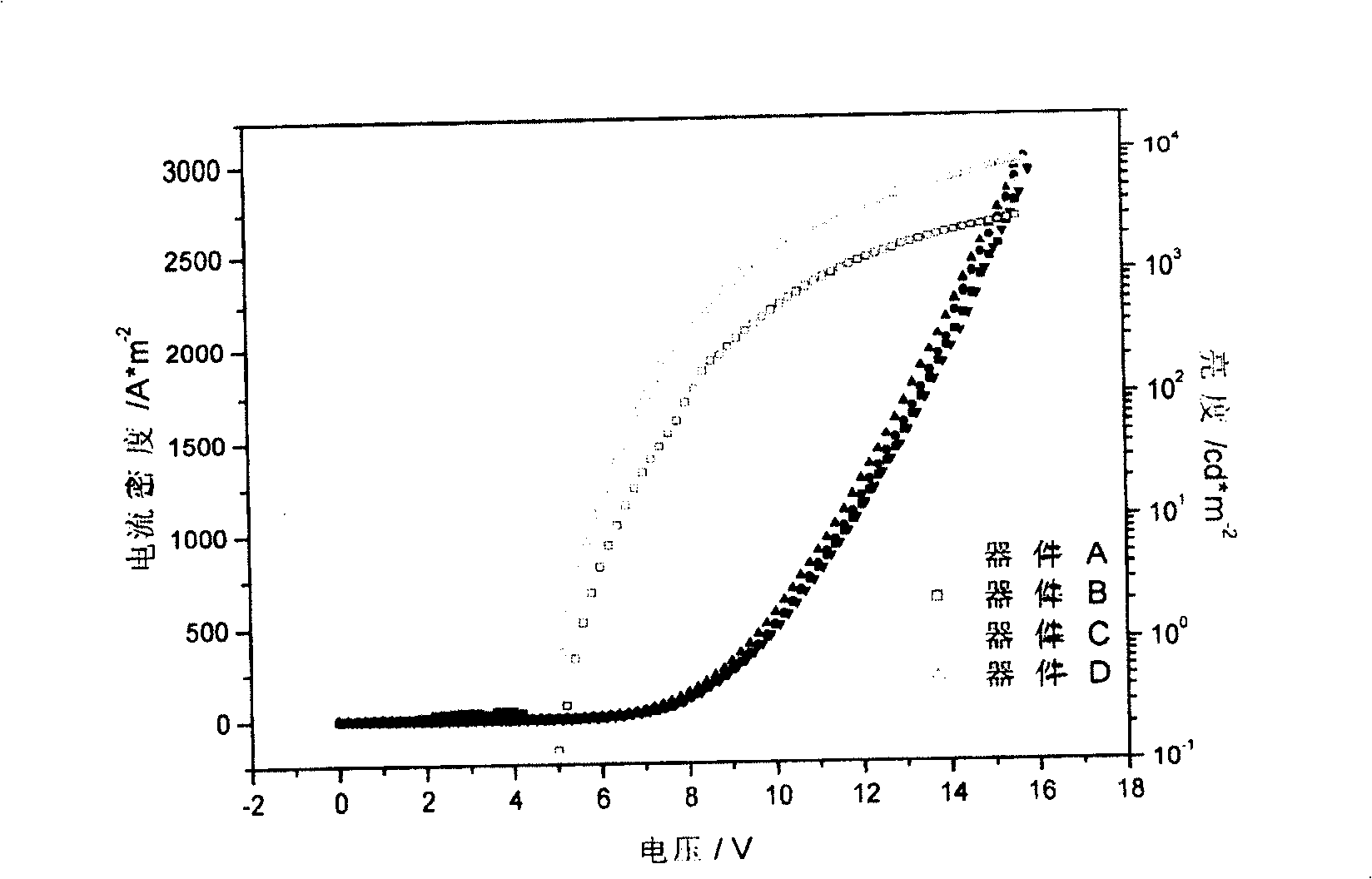

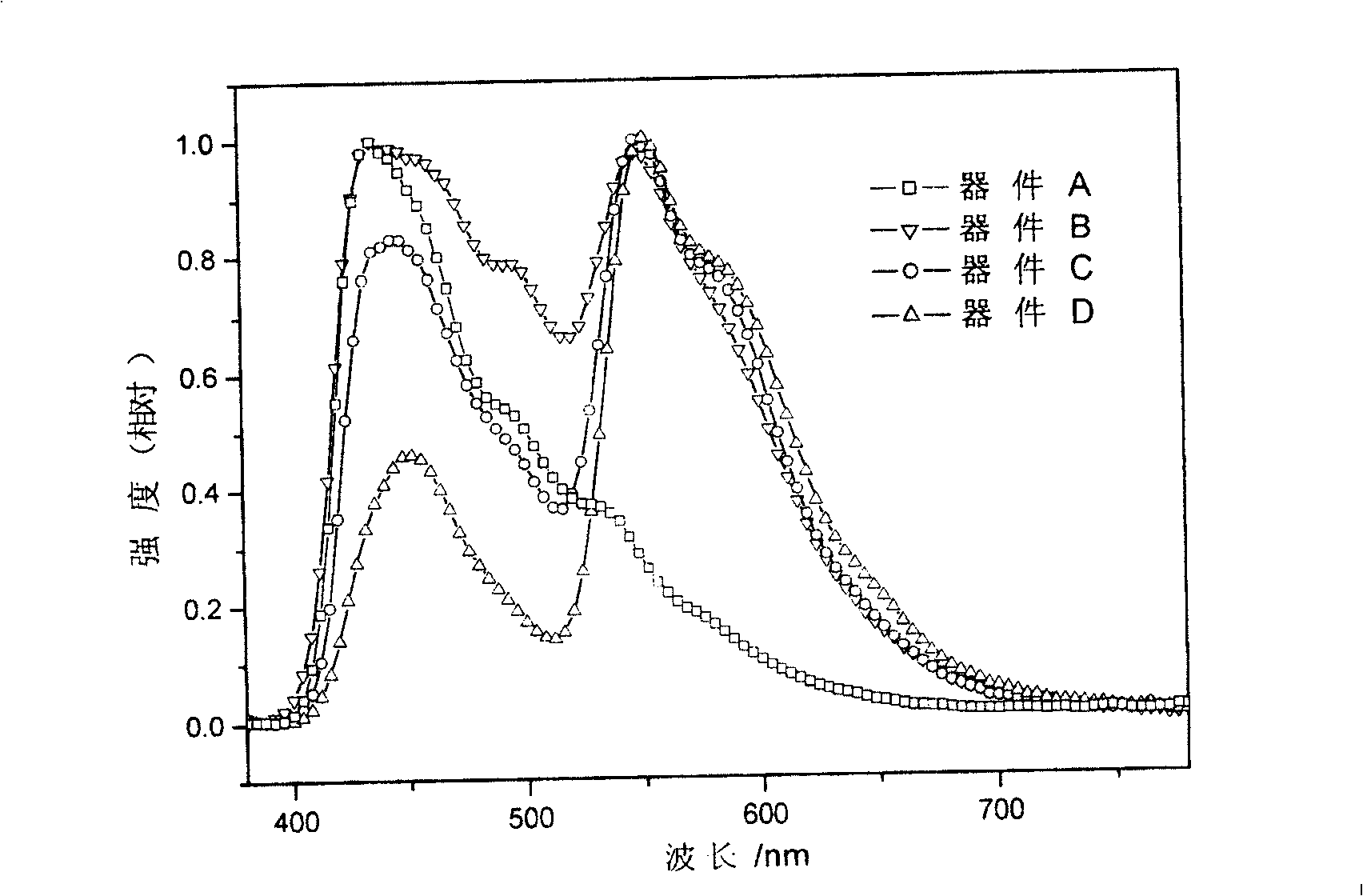

[0053] Embodiment 1: Preparation of organic electroluminescence device OLED-1 (A-D)

[0054] The glass plate coated with the transparent conductive layer of indium tin oxide is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone: ethanol mixed solvent, and baked in a clean environment until the water is completely removed , irradiated with a UV light cleaner for 10 minutes, and bombarded the surface with a low-energy positive ion beam.

[0055] A 50 nm thick 4,4'-bis[1-naphthyl]-N-anilino]-biphenyl hole transport layer was deposited on indium tin oxide by thermal evaporation.

[0056] Mix solid material 99% 99% 9,9,10-bis(2-naphthyl)anthracene and 1% rubrene according to molar percentage, then melt the mixture in a container with a chemically inert environment, cool to room temperature, and take it out from the container Uniform pre-doped luminescent material, put it into evaporation source 1, put 9,9,10-bis(2-...

Embodiment 2

[0067] The glass plate coated with the transparent conductive layer of indium tin oxide is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone: ethanol mixed solvent, and baked in a clean environment until the water is completely removed , irradiated with a UV light cleaner for 10 minutes, and bombarded the surface with a low-energy positive ion beam.

[0068] A 50 nm thick 4,4'-bis[1-naphthyl]-N-anilino]-biphenyl hole transport layer was deposited on indium tin oxide by thermal evaporation.

[0069] Mix solid material 99% 99% 9,9,10-bis(2-naphthyl)anthracene and 1% rubrene according to molar percentage, then melt the mixture in a container with a chemically inert environment, cool to room temperature, and take it out from the container Uniform pre-doped luminescent material, put it into evaporation source 1, put 9,9,10-bis(2-naphthyl)anthracene in evaporation source 2, control the evaporation rate of evaporatio...

Embodiment 3

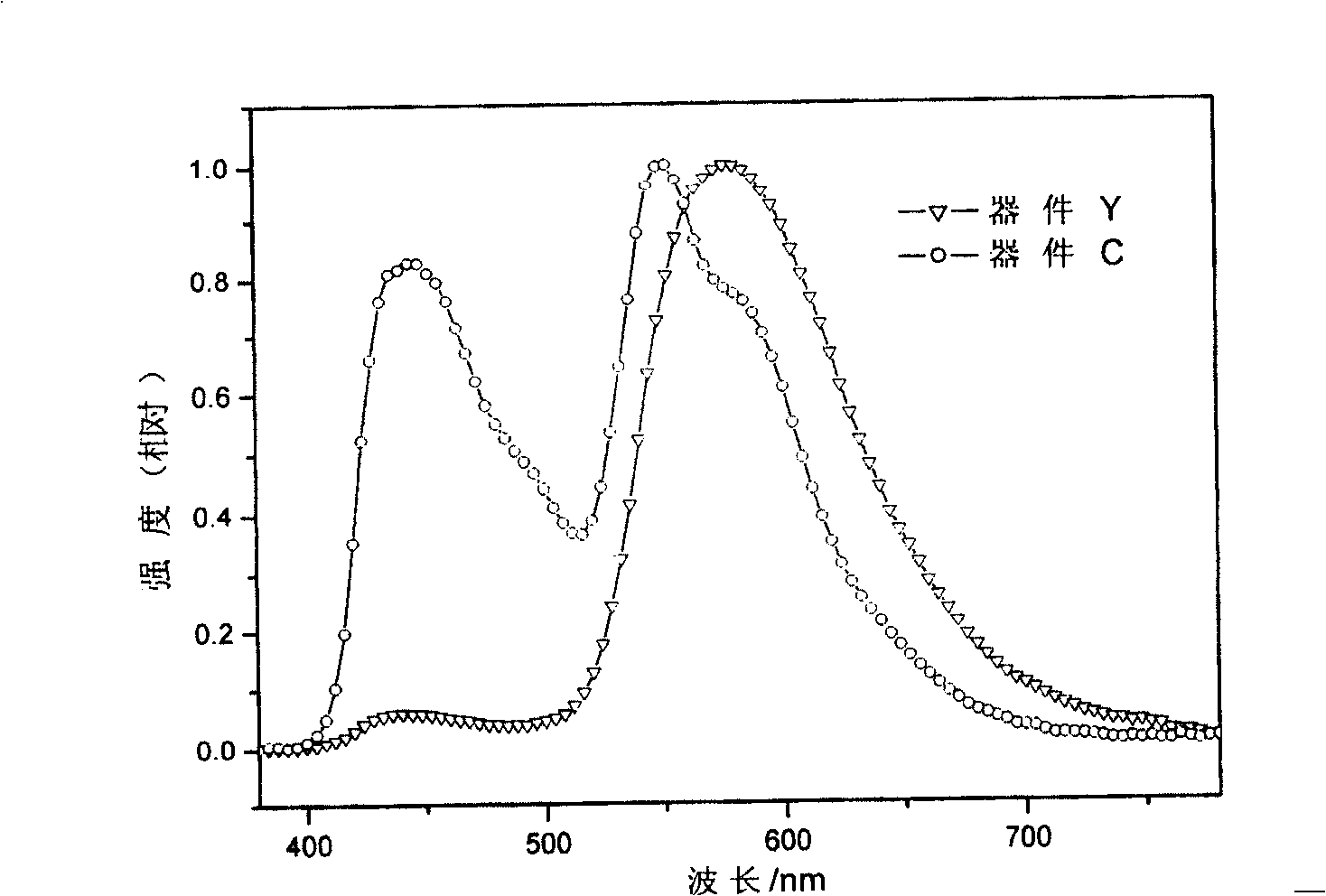

[0075] Embodiment 3: Preparation of organic electroluminescent device OLED-2 (A-D)

[0076] The glass plate coated with the transparent conductive layer of indium tin oxide is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone: ethanol mixed solvent, and baked in a clean environment until the water is completely removed , irradiated with a UV light cleaner for 10 minutes, and bombarded the surface with a low-energy positive ion beam.

[0077] A 50 nm thick 4,4'-bis[1-naphthyl]-N-anilino]-biphenyl hole transport layer was deposited on indium tin oxide by thermal evaporation.

[0078] Mix solid material 99% 2-tert-butyl-9,10-bis(2-naphthyl)anthracene and 1% rubrene according to molar percentage, then melt the mixture in a container with a chemically inert environment, cool to room temperature, Take out the uniform pre-doped luminescent material from the container, put it into evaporation source 1, put 9,9,10-di(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com