Method for producing centre tube of reactor

A manufacturing method and center tube technology, applied to chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low work efficiency, small tube diameter, and inability to adapt to capacity expansion and transformation, and achieve significant economic benefits and scientific process methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

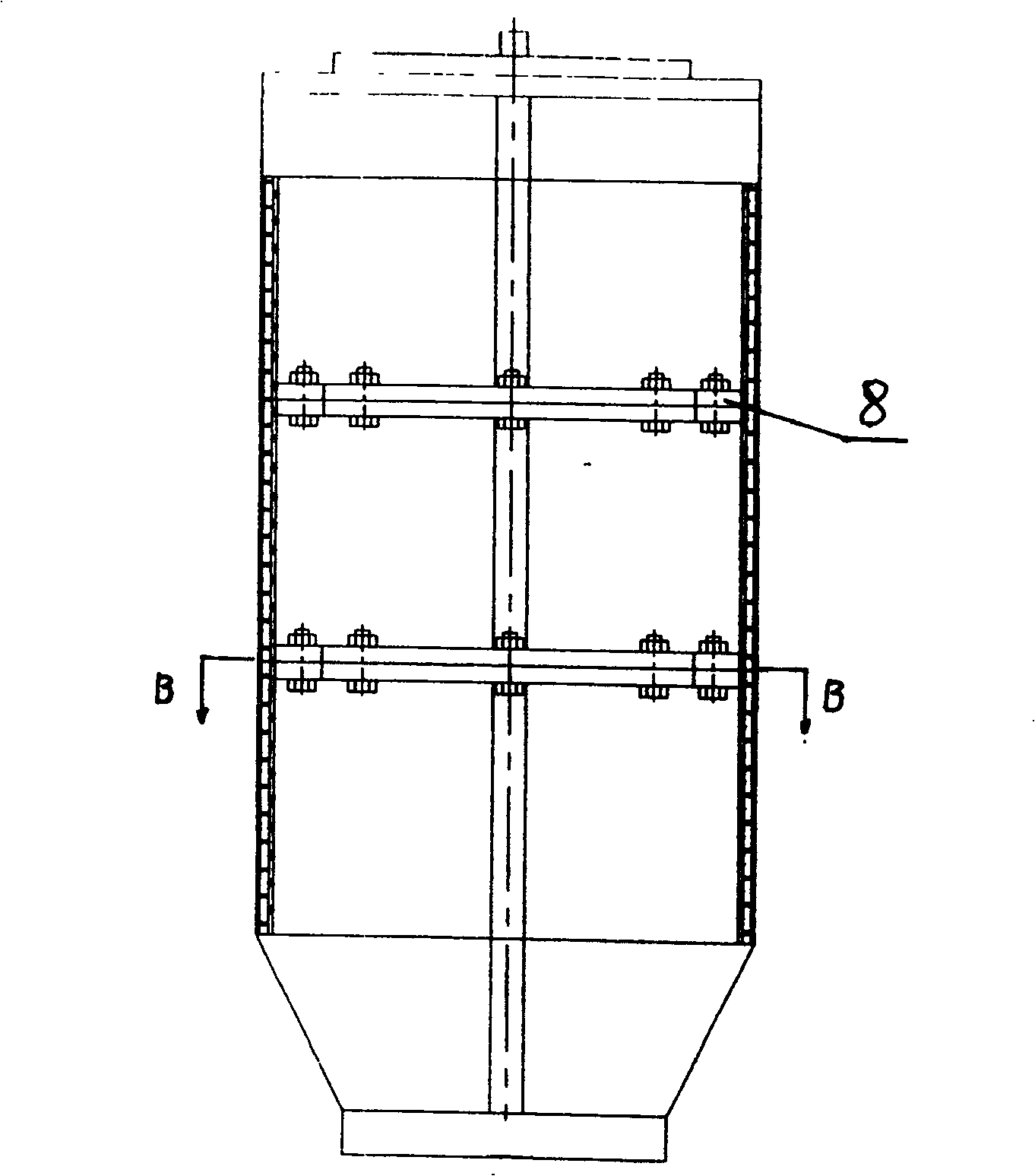

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

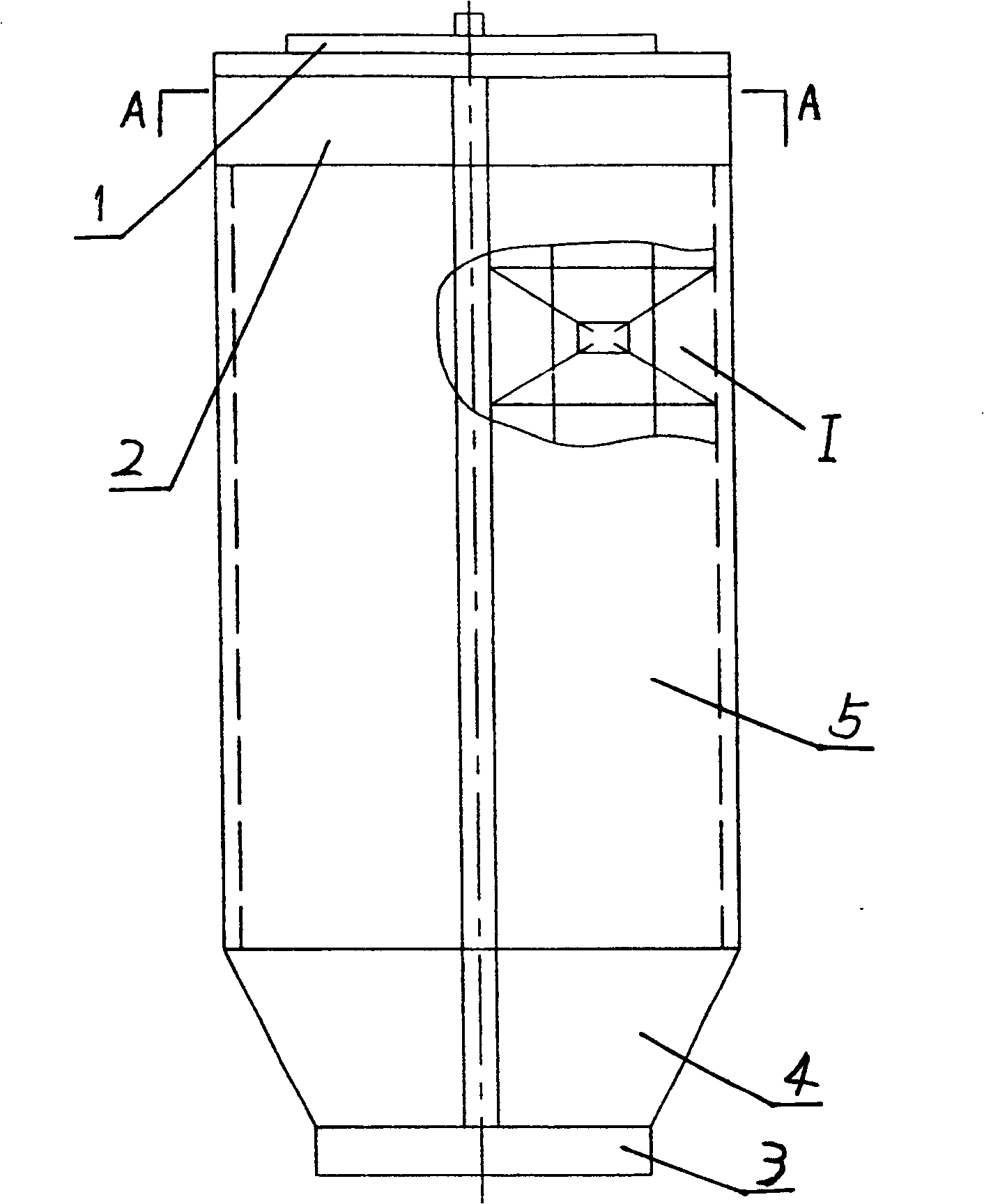

[0014] A kind of manufacture method of central tube of reactor, see attached figure 1 , the central tube of the reforming reactor is composed of the central tube top cover 1, the upper blind tube 2, the center tube hole and the strip welded mesh 5, the lower blind tube 4 and the central tube base 3. In order to realize the purpose of the invention, the present invention adopts the technical scheme of increasing the diameter of the central tube on the basis of not changing the reactor to make the central tube of the reactor, and its manufacturing method is as follows:

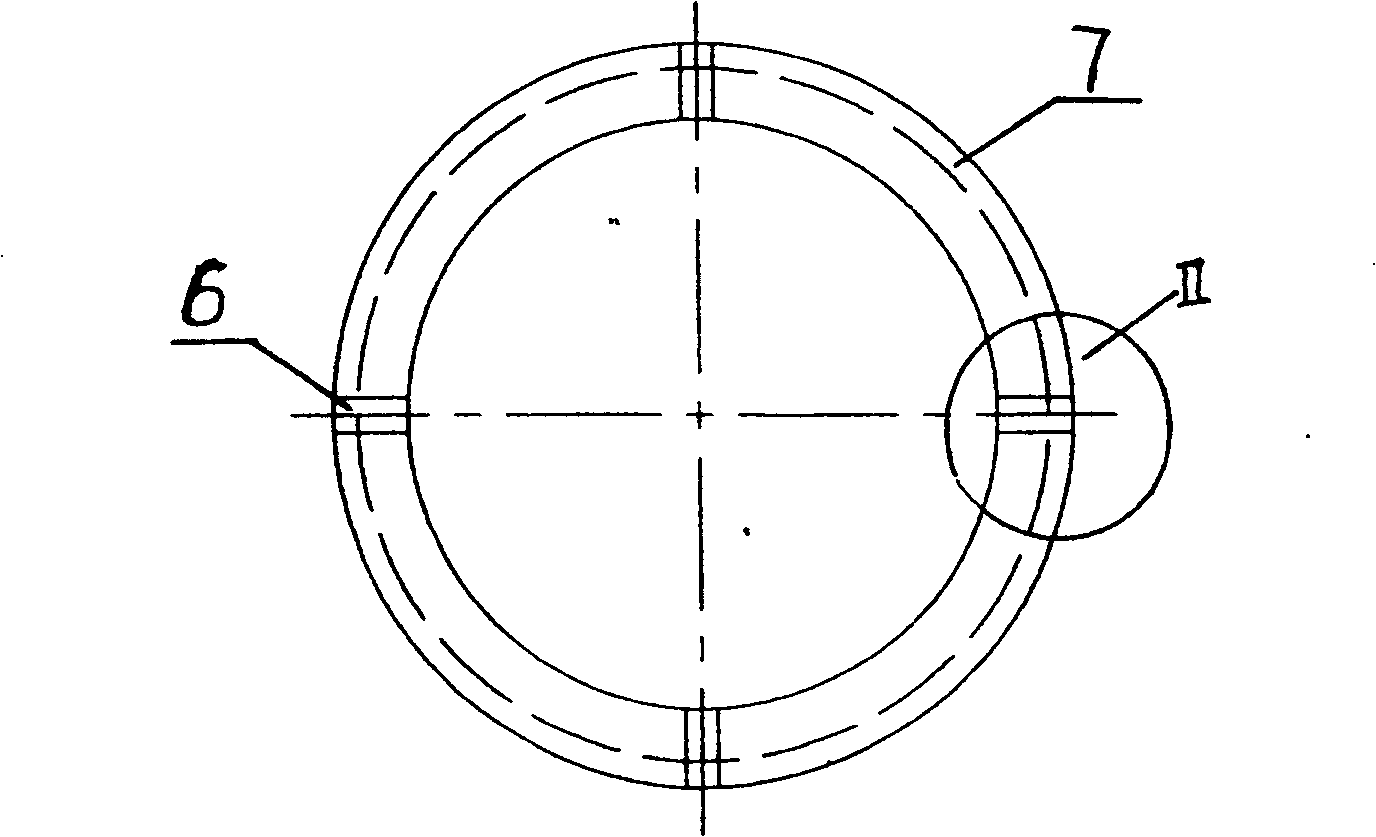

[0015] Such as figure 1 , figure 2 , along the (axis) radial direction of the central tube, the central tube is rationally divided into multiple lobes (at least 3 lobes) according to the design requirements, and the present invention divides it into four lobes, each of which is an annular split 7. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com