Braking energy feeding control method of electric automobile

A braking energy feedback, electric vehicle technology, applied in electric vehicles, electric braking systems, brakes, etc., can solve problems such as difficulty in obtaining satisfactory results, locking, actively avoiding wheels, etc., and achieve high braking energy feedback efficiency, Avoid wheel lock, avoid the effect of complex operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

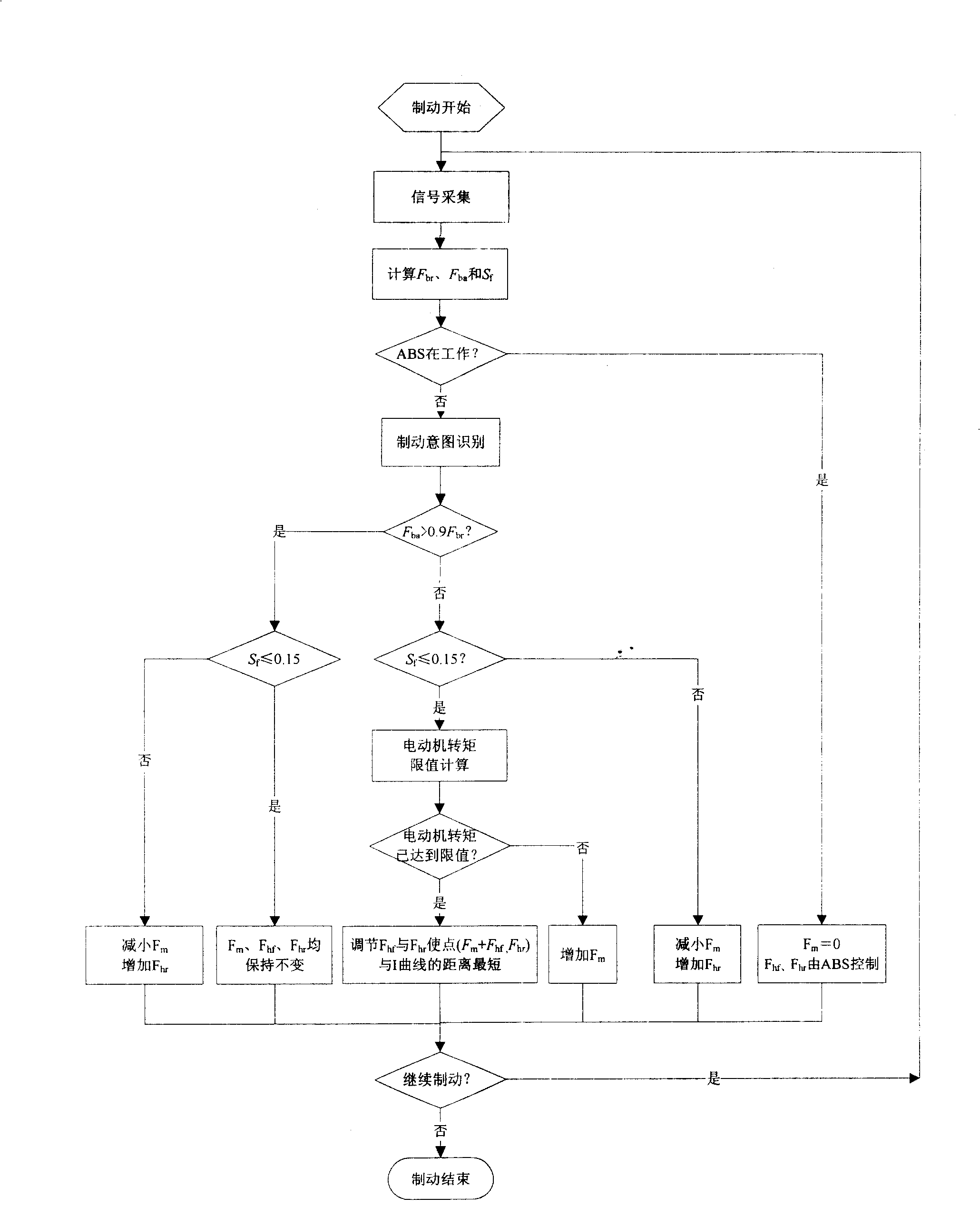

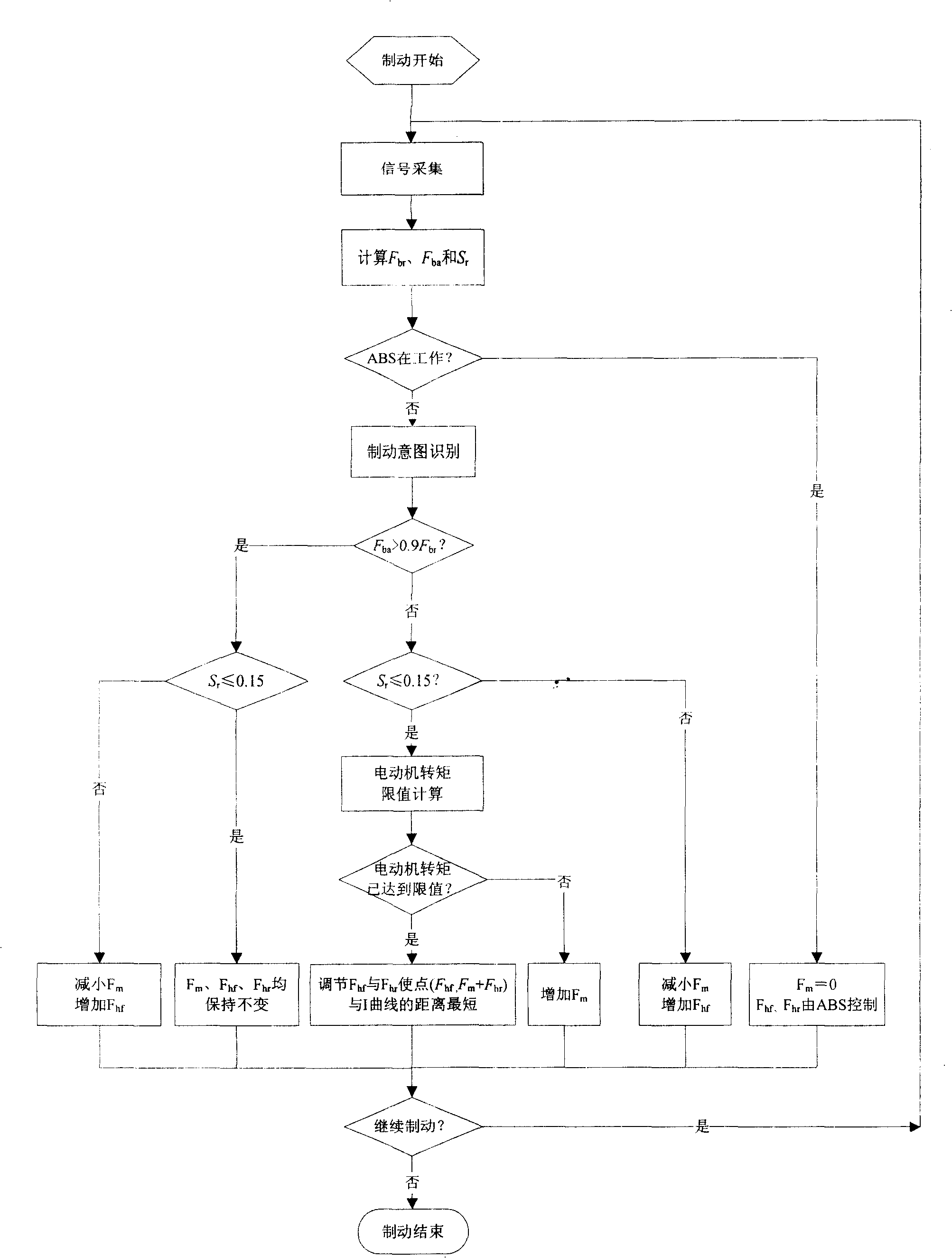

[0043] Combine below figure 1 , 2 The invention is further described as follows.

[0044] Embodiment 1 of the brake energy feedback control method used in the front axle electric drive vehicle of the present invention is as follows: figure 1 shown, including the following steps:

[0045] 1) After receiving the pressure signal from the brake master cylinder (the pressure signal generated when the driver depresses the brake pedal), the brake starts;

[0046] 2) Collect signals such as brake master cylinder pressure, brake pedal stroke, motor torque, wheel speed and vehicle acceleration, and calculate the driver's required braking force F br , The actual braking force F of the vehicle ba , front axle wheel slip ratio S f (belonging to conventional technology in the art);

[0047] 3) Adjust the front axle hydraulic braking force F hf , Rear axle hydraulic braking force F hr with electric motor braking force Fm ; The specific adjustment is:

[0048] (1) If the ABS is worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com