Device for holding a load on a load support of an industrial truck

A technology for fixing devices, supporting devices, applied in the direction of lifting devices, etc., can solve problems such as weight and complexity constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

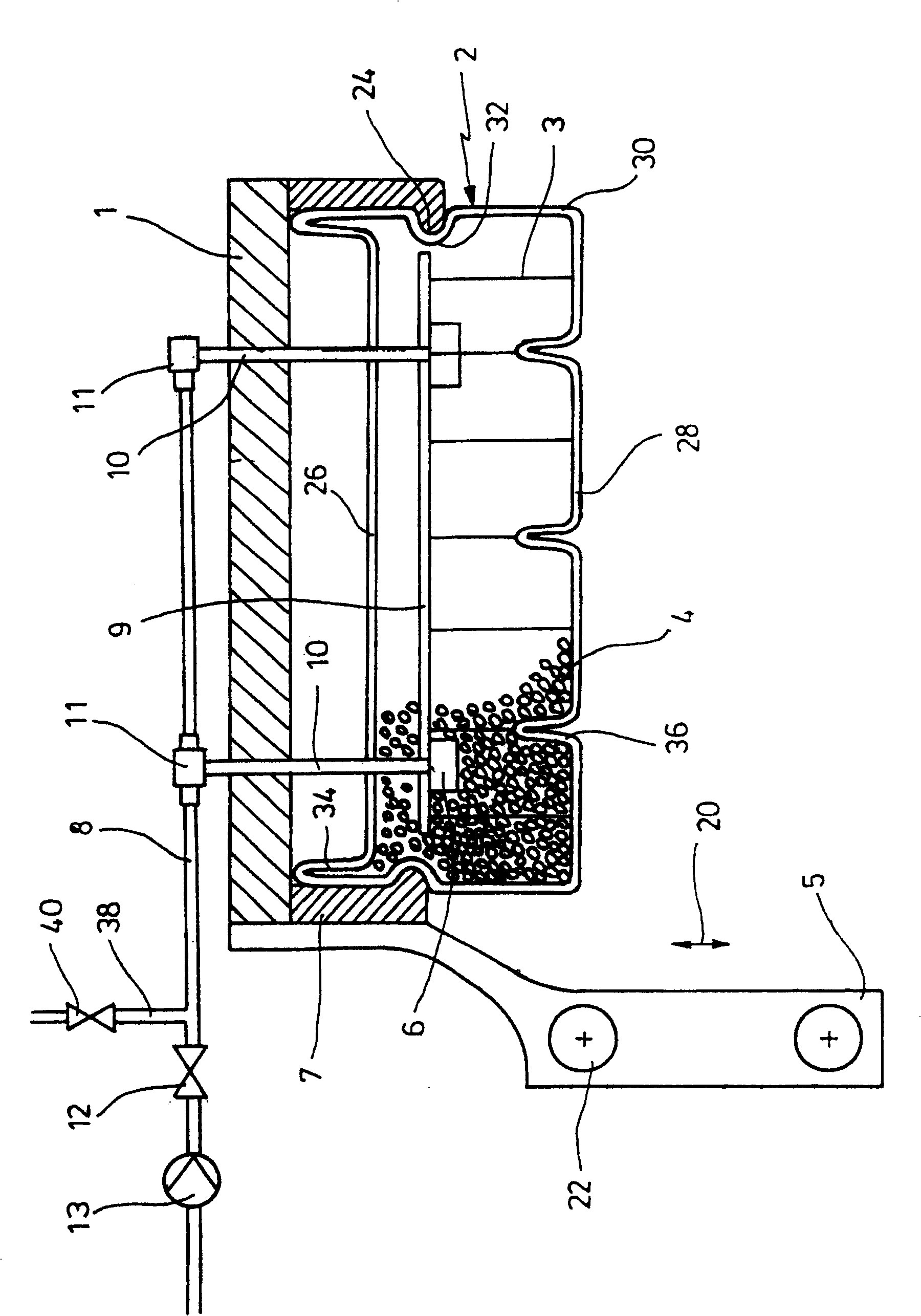

[0018] The fixed plate 1 is mounted on the guide portion 5 . The guide part 5 is in the lifting frame of a not shown industrial truck, in a manner independent of the load carrier, the guide is displaceable on its height and can be driven by a not shown lifting gear. The lifting drive comprises, for example, a hydraulic or pneumatic lifting cylinder, a shaft drive, a threaded shaft or the like. Altitude movement reservations are indicated by double arrows 20 . In addition, rollers 22 are shown, which are guided on corresponding guide rails of a lift carriage, not shown.

[0019] On the fixed plate 1, a frame 7 is mounted so as to rotate horizontally around. The frame can have a circular or rectangular shape. The dimensions and shape roughly correspond to the standing area of transported objects on standardized pallets. However, other shapes and sizes are also conceivable. The wall of the frame 7 has a bead 24 protruding inwards inside the bottom side.

[0020] A pouch-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com