Nematic liquid-crystal composition and liquid-crystal display element employing the same

A technology of liquid crystal composition and compound, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of high viscosity, large absolute value of anisotropy, slow response speed of liquid crystal display elements, etc., and achieve low viscosity, wide range of Liquid crystal temperature range, effect of large dielectric constant anisotropy

Inactive Publication Date: 2008-11-05

DAINIPPON INK & CHEM INC

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the liquid crystal composition using a compound having 1,7,8-trifluoronaphthyl-2,6-diyl, there is no specific description of which compound is used to constitute the composition in order to achieve the above-mentioned problem.

In addition, as the characteristics of the compound monomer, it is characterized in that the absolute value of the negative dielectric constant anisotropy is large, and the nematic phase-isotropic liquid phase transition temperature (T N-I ) is also high, but the problem is that the viscosity is relatively high, and the response speed of the liquid crystal display device using this compound is not fast

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0106] The following liquid crystal compositions were prepared and their properties were measured.

[0107]

Embodiment 2

[0109] The following liquid crystal compositions were prepared and their properties were measured.

[0110]

Embodiment 3

[0112] The following liquid crystal compositions were prepared and their properties were measured.

[0113]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a nematic liquid-crystal composition having negative dielectric anisotropy which contains 10 to 70 wt.% at least one compound selected among the compounds represented by the formulae (IA) and (IB) and 10 to 70 wt.% at least one compound selected among the compounds represented by the formulae (IIA) to (IID), the total content of the compounds represented by the formulae (IA) to (IID) being 35 to 80 wt.%, and further contains 20 to 65 wt.% compound represented by the formula (III).

Description

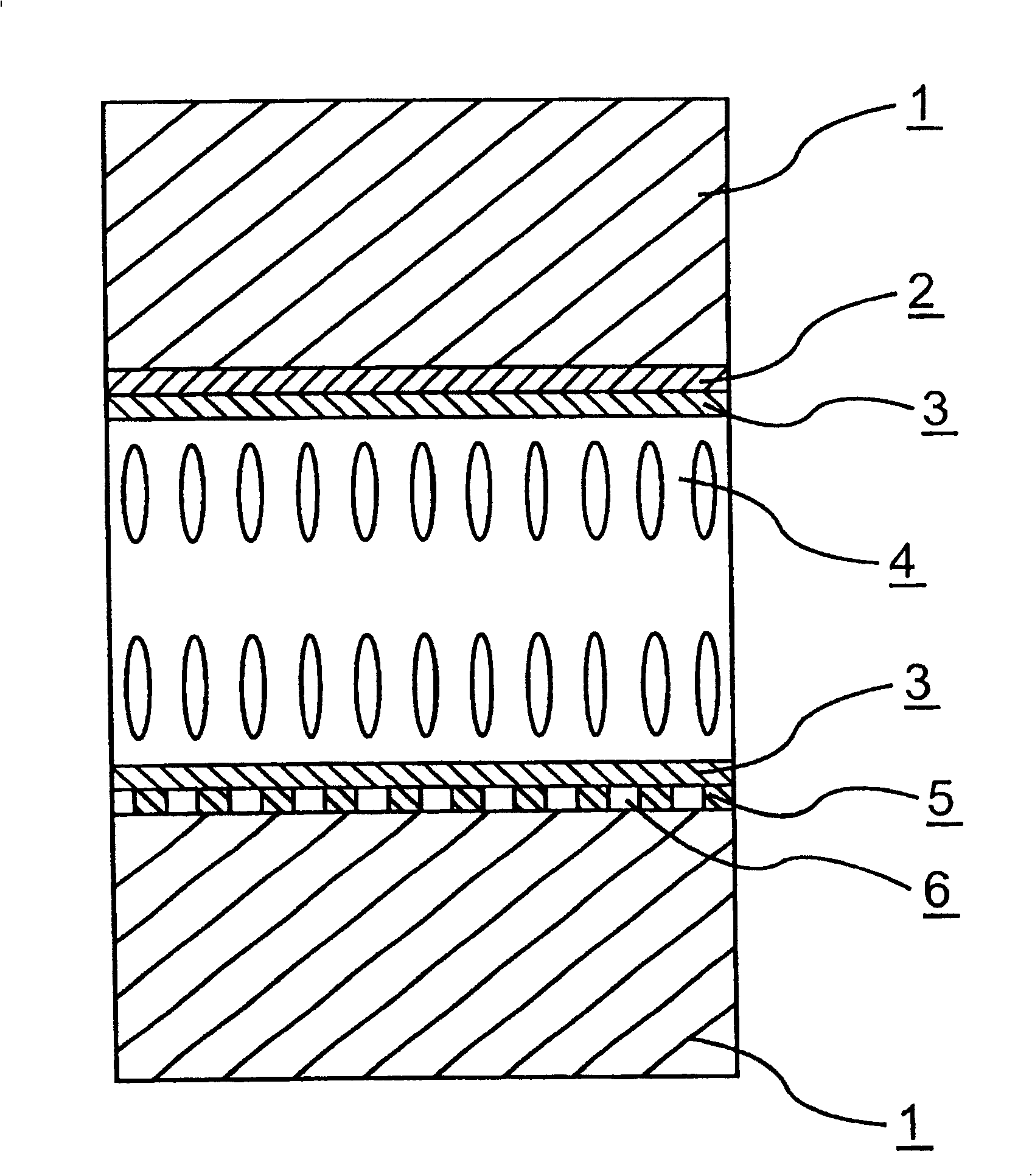

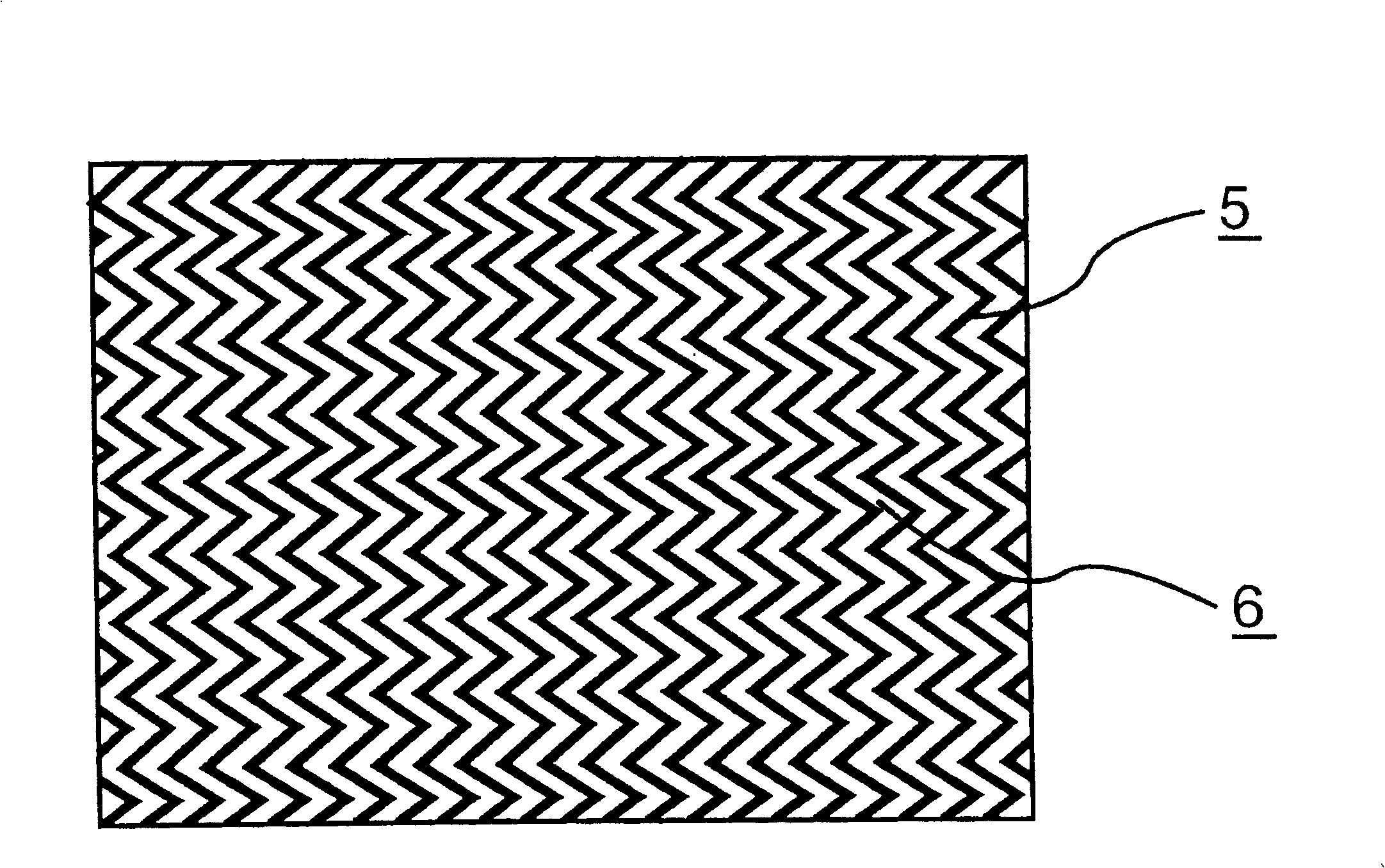

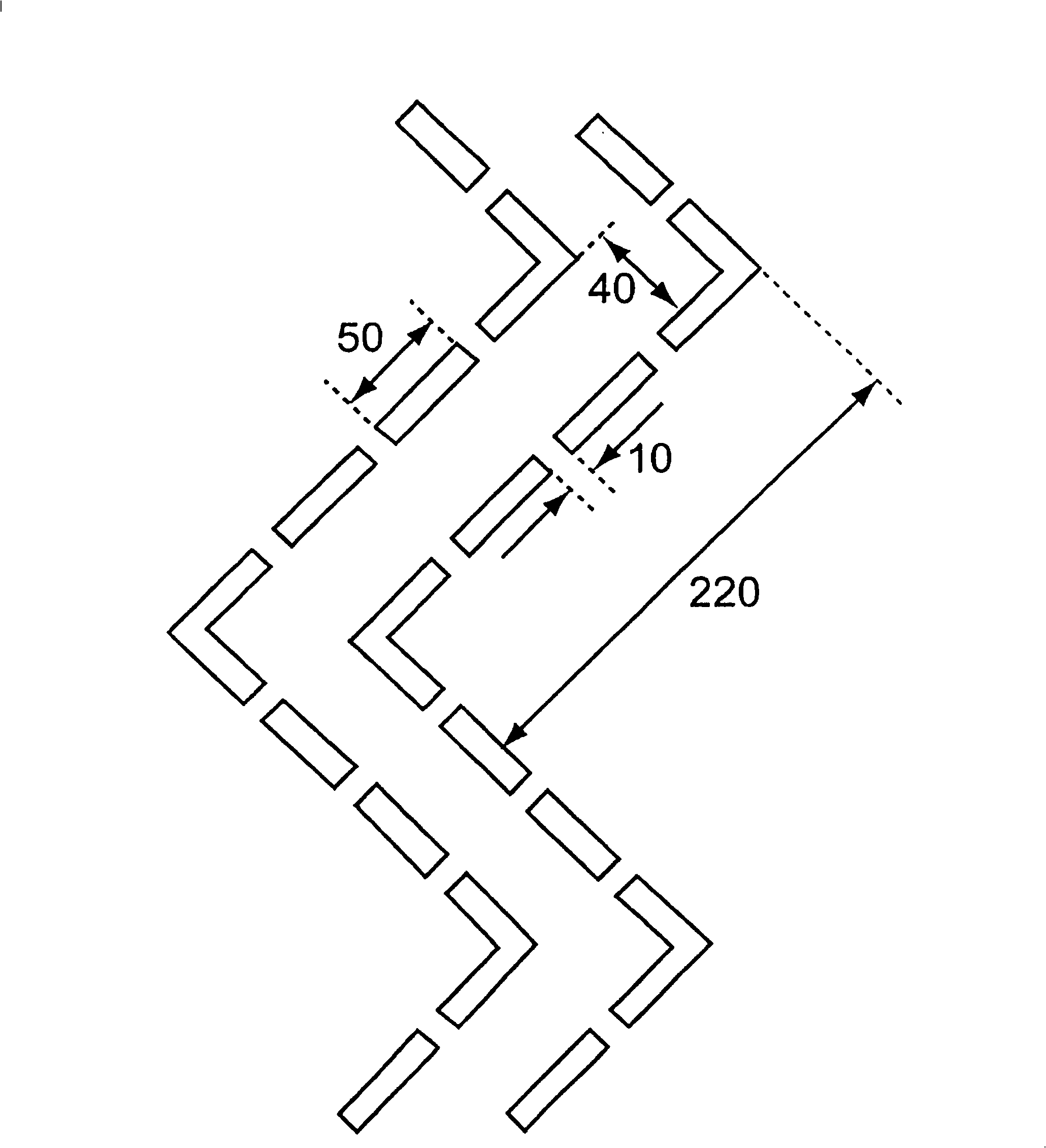

technical field [0001] The present invention relates to a nematic liquid crystal composition having physical properties most suitable for a liquid crystal display element and negative dielectric constant anisotropy, and a liquid crystal display element using the composition. Background technique [0002] The widely used TN (twisted nematic) type liquid crystal display element or STN (super twisted nematic) type liquid crystal display element has the problem of poor viewing angle characteristics due to changes in electro-optical characteristics due to its viewing angle. This becomes a big problem in applications where viewing angle characteristics are relatively important, such as TV. As methods for obtaining a larger viewing angle, VA (Vertically aligned) method (VA mode) (see Non-Patent Document 1), IPS (In-Plane Switching) method (IPS mode) (see Non-Patent Document 2), ECB (electrically controlled birefringence) method (ECB mode), etc., have been put into practical use. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K19/42C09K19/32G02F1/13

Inventor 田中芳清竹内清文高津晴义

Owner DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com