Construction method for burner, air channels, gas flues inside furnace wall of heating furnace in heat storage type

A technology of air passage and construction method, which is applied in combustion methods, lighting and heating equipment, combustion using block fuel and liquid fuel, etc. and other problems to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

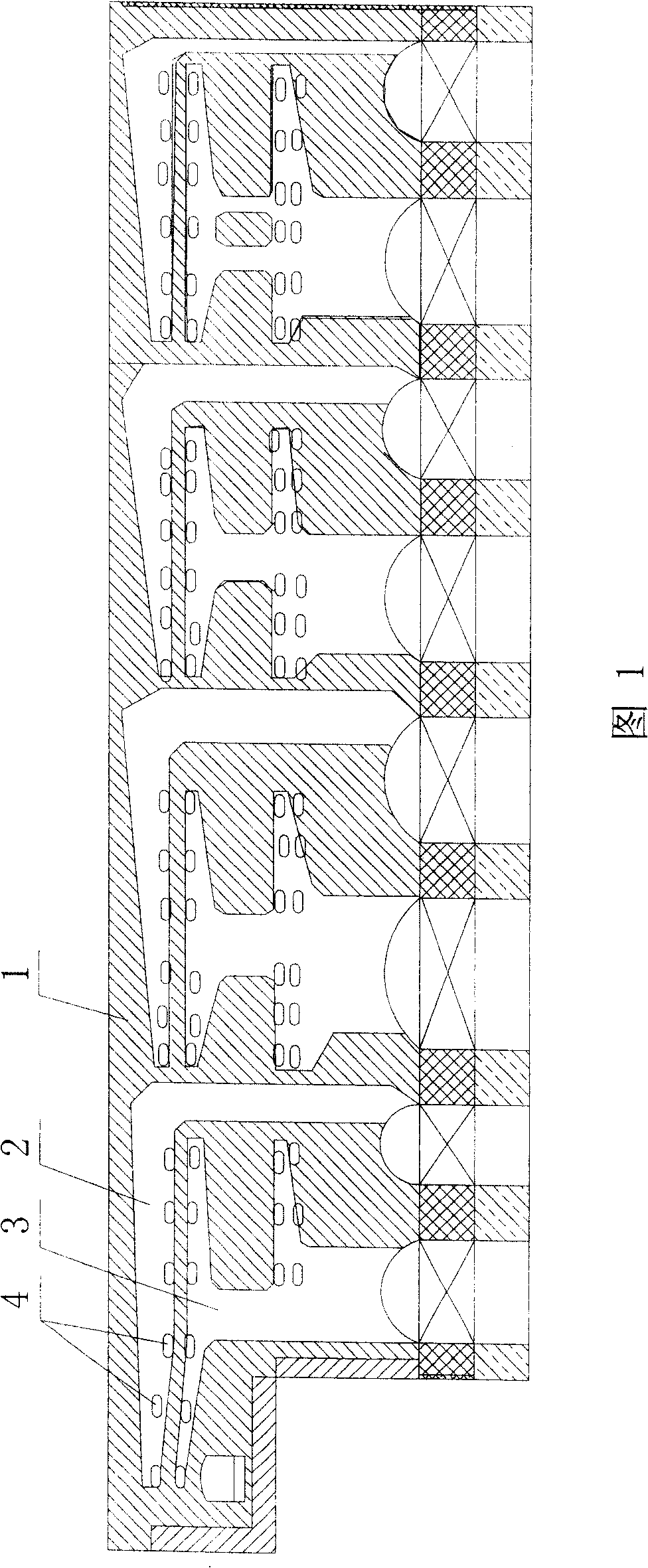

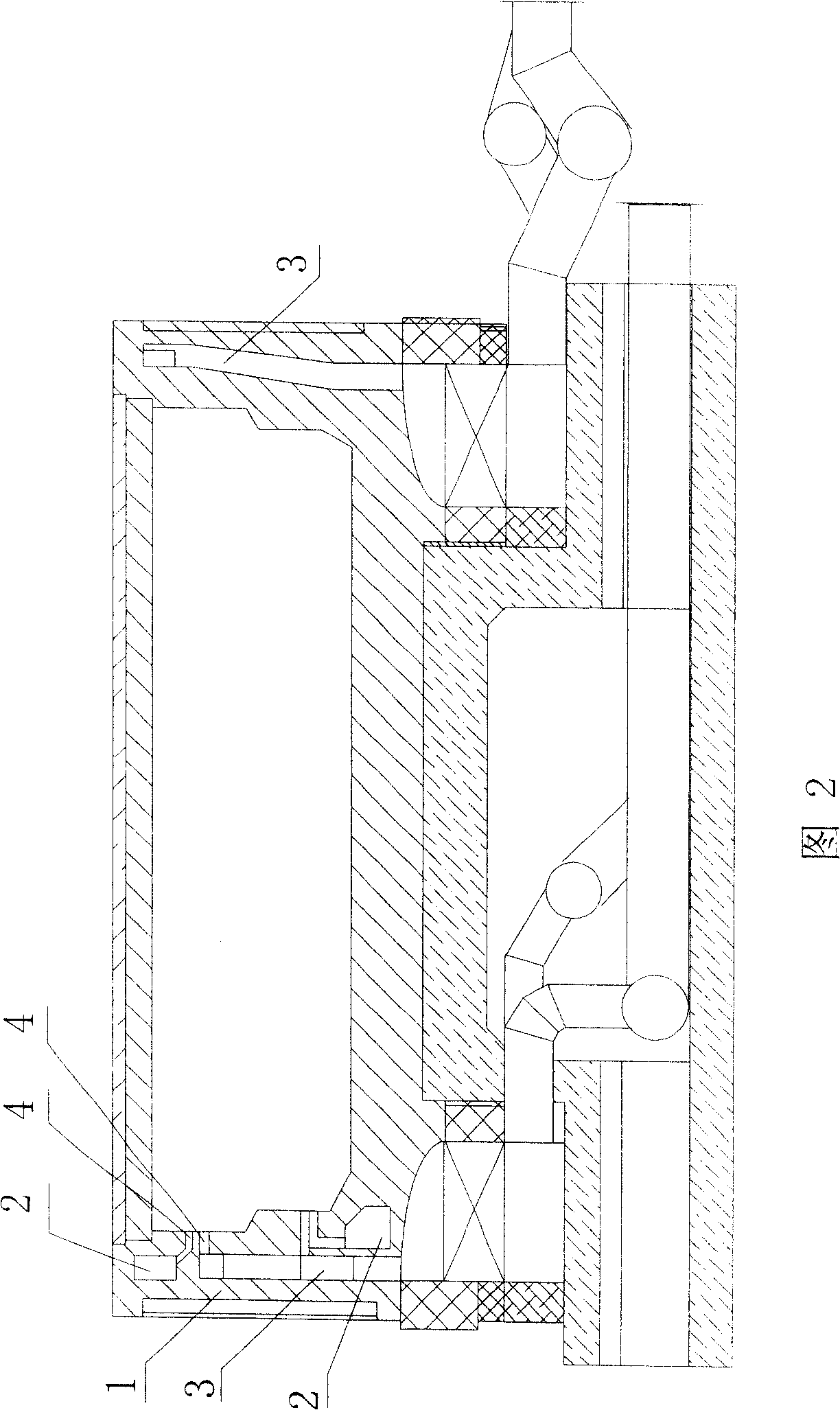

[0014] As shown in Figure 1 and Figure 2, the regenerative heating furnace adopts the existing waste heat self-recovery industrial furnace, and the furnace walls on both sides of the regenerative heating furnace are arranged in groups of burners, air channels, and gas channels; Among Fig. 1, Fig. 2: 1-furnace wall, 2-air channel (flue gas channel), 3-coal gas channel, 4-burner.

[0015] The construction method of the burner, the air channel and the gas channel in the furnace wall of the regenerative heating furnace includes the following steps:

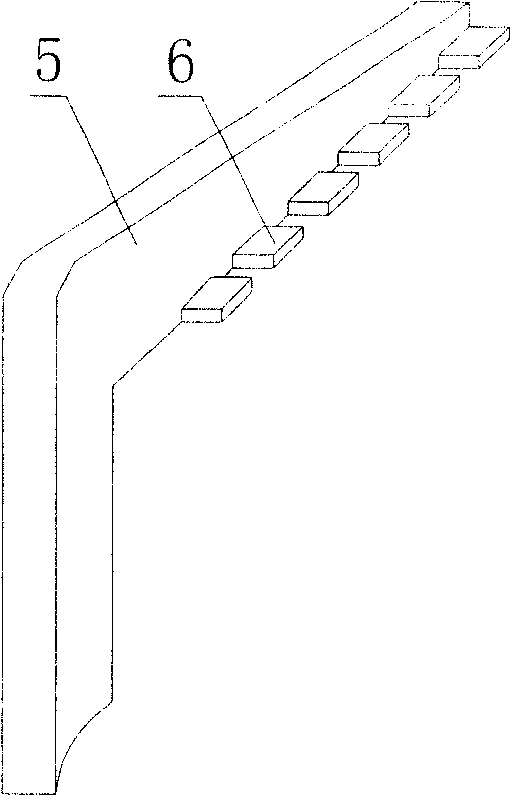

[0016] 1). According to the design dimensions of the burners, air passages and gas passages in the furnace walls on both sides of the regenerative heating furnace, draw the template diagram of the burners, air passages and gas passages in the furnace wall; make the burner with PVC material according to the template diagram. Cavity templates for nozzles, air passages, gas passages (such as image 3 As shown, the burner cavity formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com