Mending system and method of spot zone of flat plate display

A flat-panel display and bright spot technology, which is applied to instruments, nonlinear optics, optics, etc., can solve problems such as reducing the intensity of the flat-panel display 1, breaking the filter substrate 13, and shortening the service life of the flat-panel display 1.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

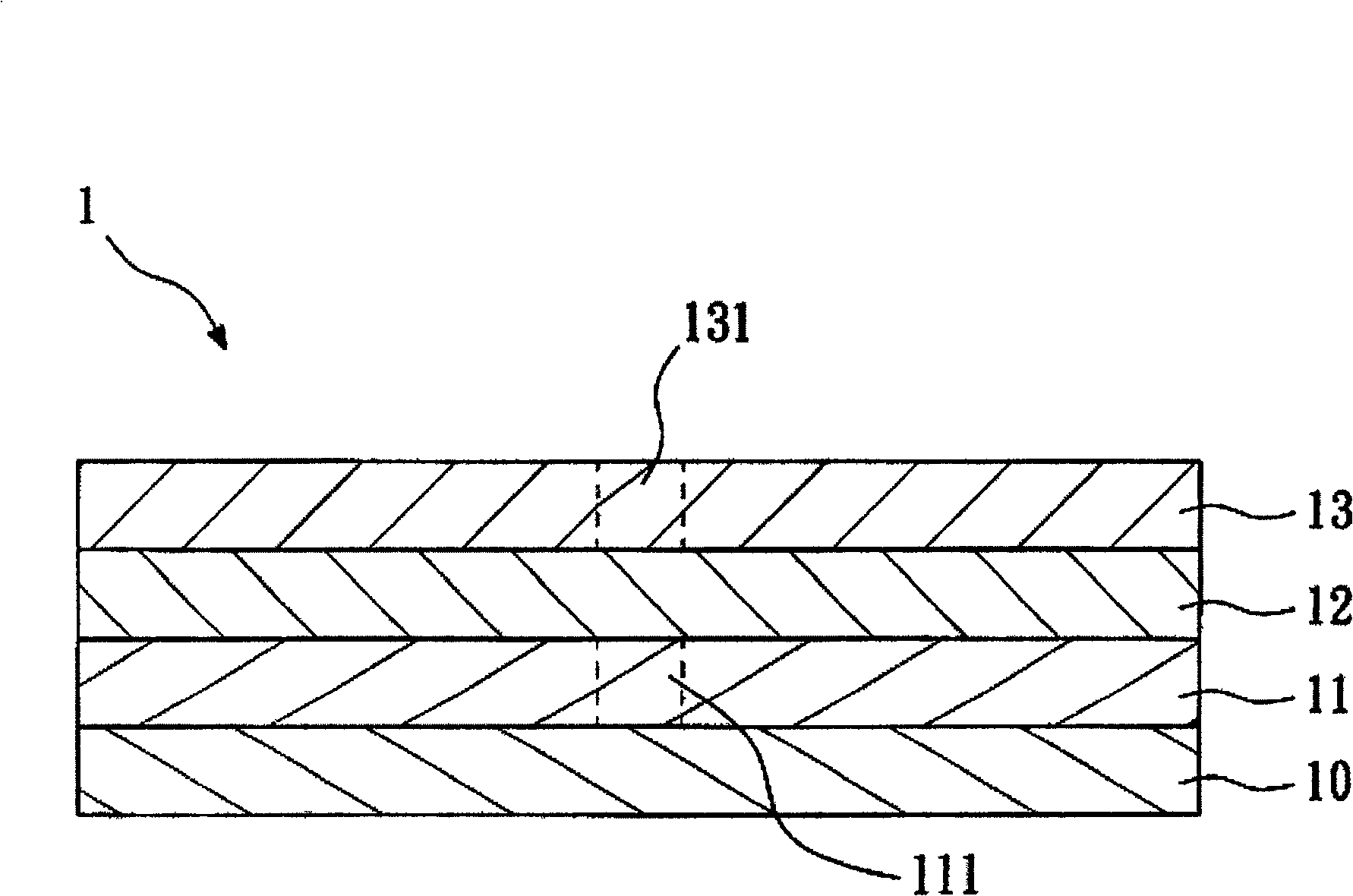

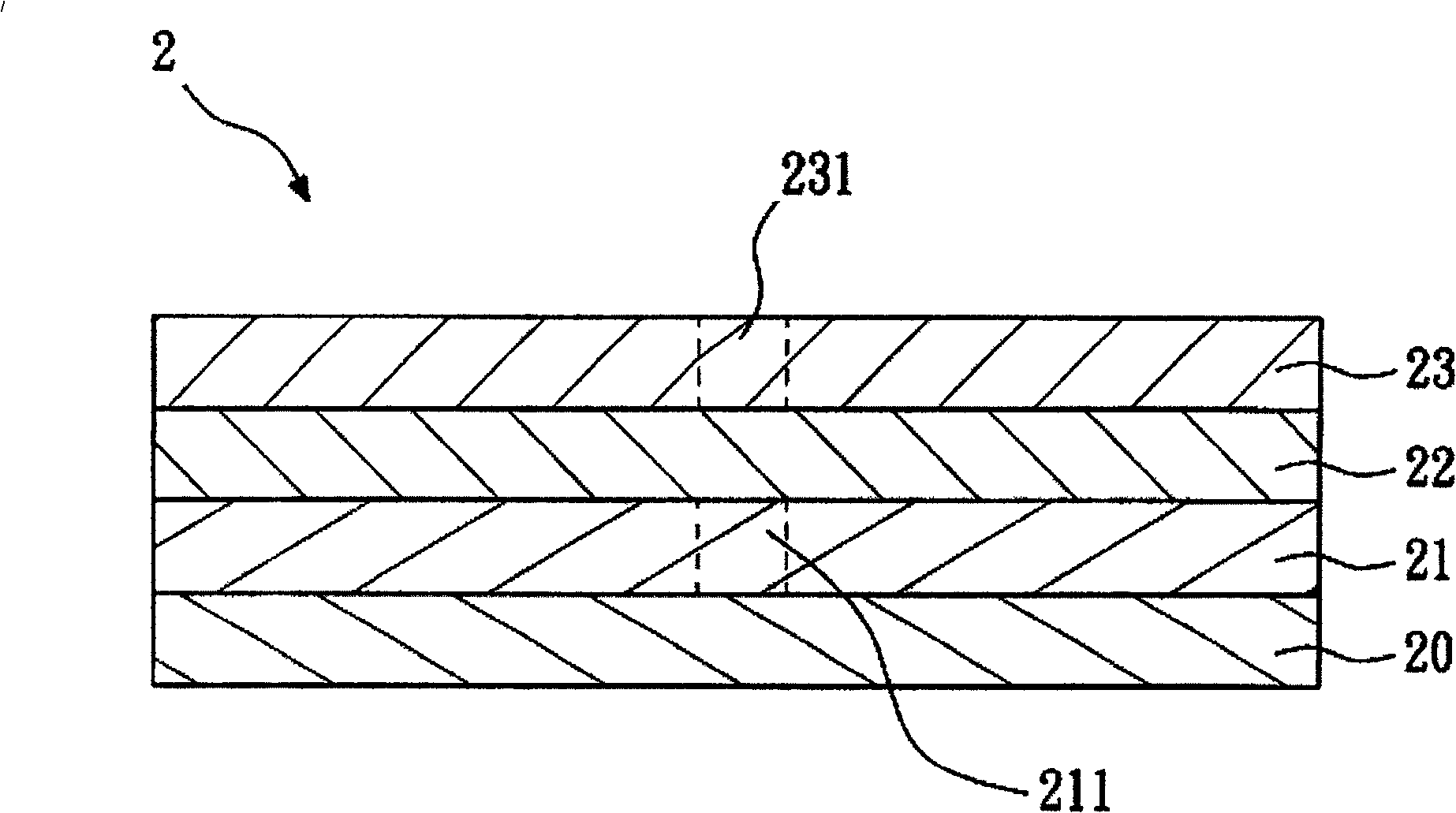

[0018] refer to image 3 , which shows a schematic diagram of the flat panel display of the present invention. The flat panel display 2 has a backlight module 20 , a TFT substrate 21 , a liquid crystal layer 22 and a filter substrate 23 . The thin film transistor substrate 21 is disposed on the backlight module 20 , the liquid crystal layer 22 is disposed on the thin film transistor substrate 21 , and the filter substrate 23 is disposed on the liquid crystal layer 22 . The TFT substrate 21 has at least one light-transmitting region 211 , and the light-transmitting region 211 cannot shield the light generated by the backlight module 20 . The filter substrate 23 has at least one bright spot area 231 , and the bright spot area 231 is at a position corresponding to the transparent area 211 .

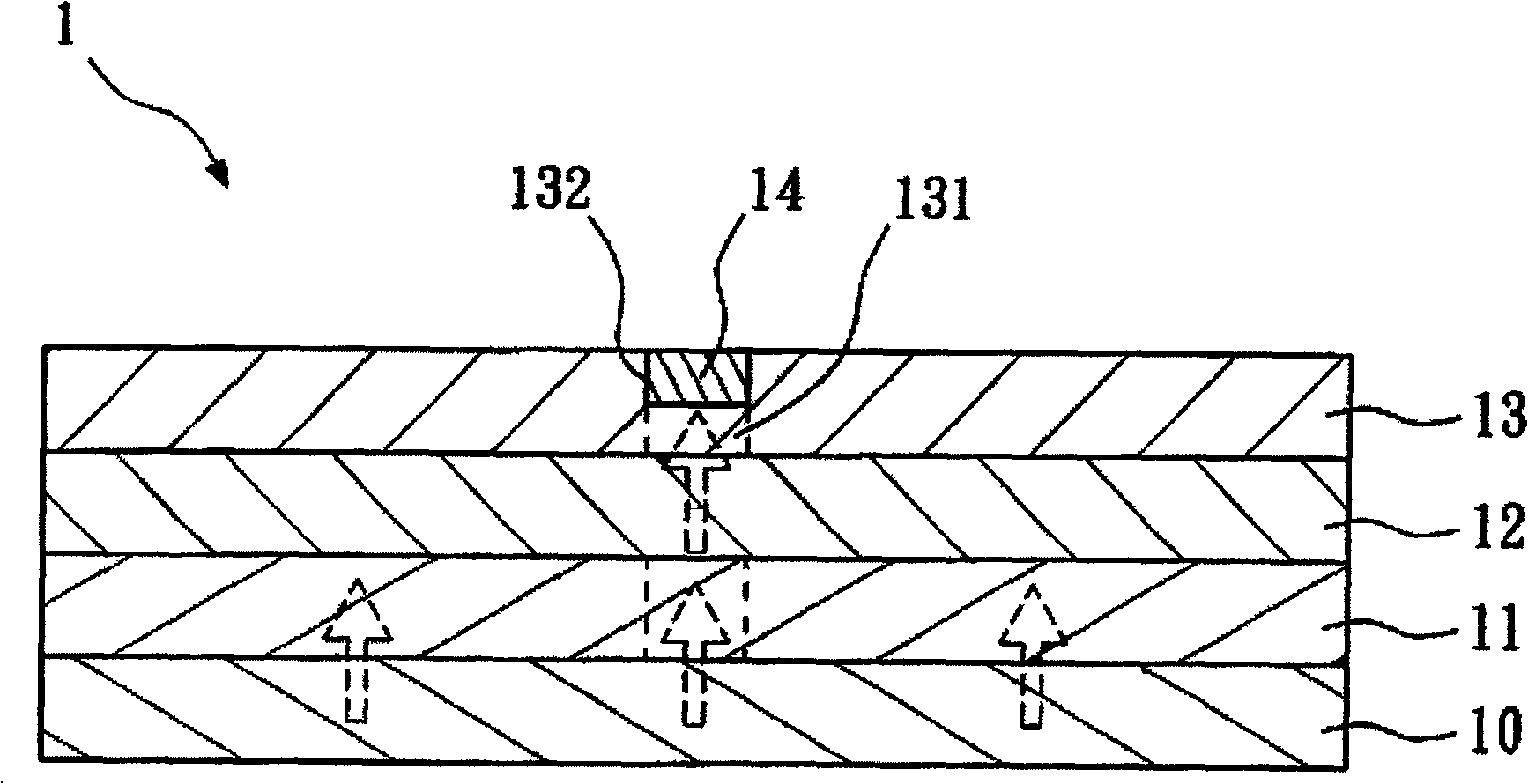

[0019] refer to Figure 4 , which shows a schematic diagram of the method for repairing the bright spot area of a flat panel display according to the present invention. First, a target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com