Inner heat exchange pipe device of solar heat collecting pipe

A solar collector tube and heat exchange tube technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of rust and water leakage at the welding place, high production cost, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

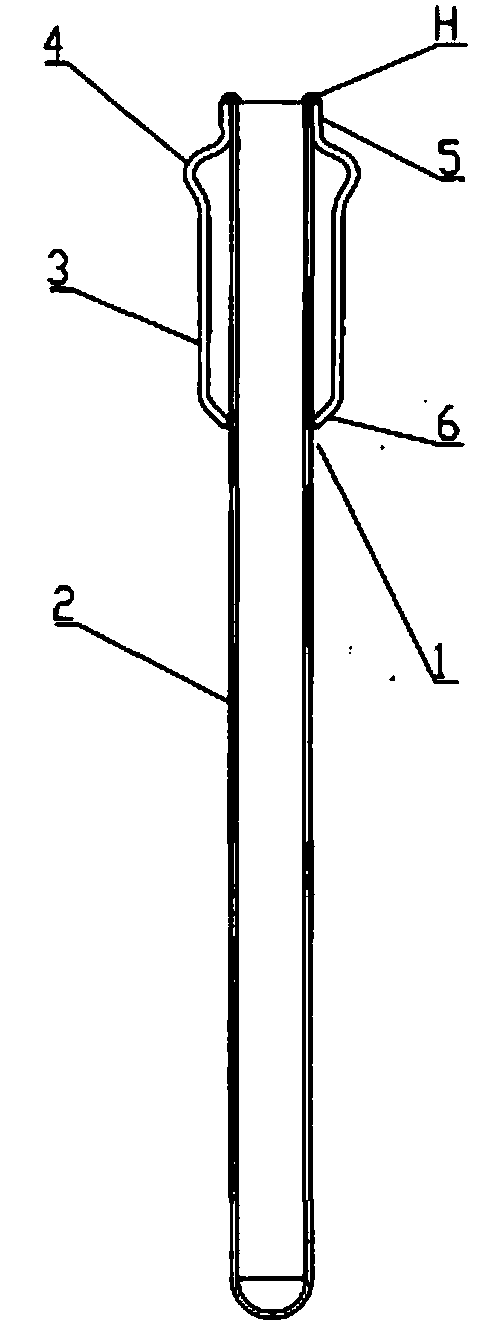

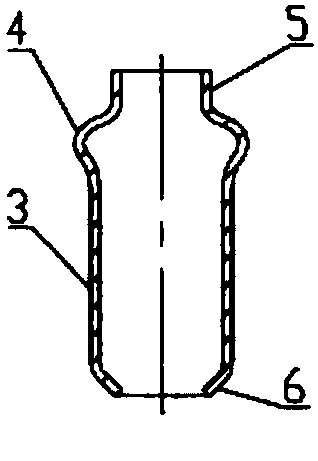

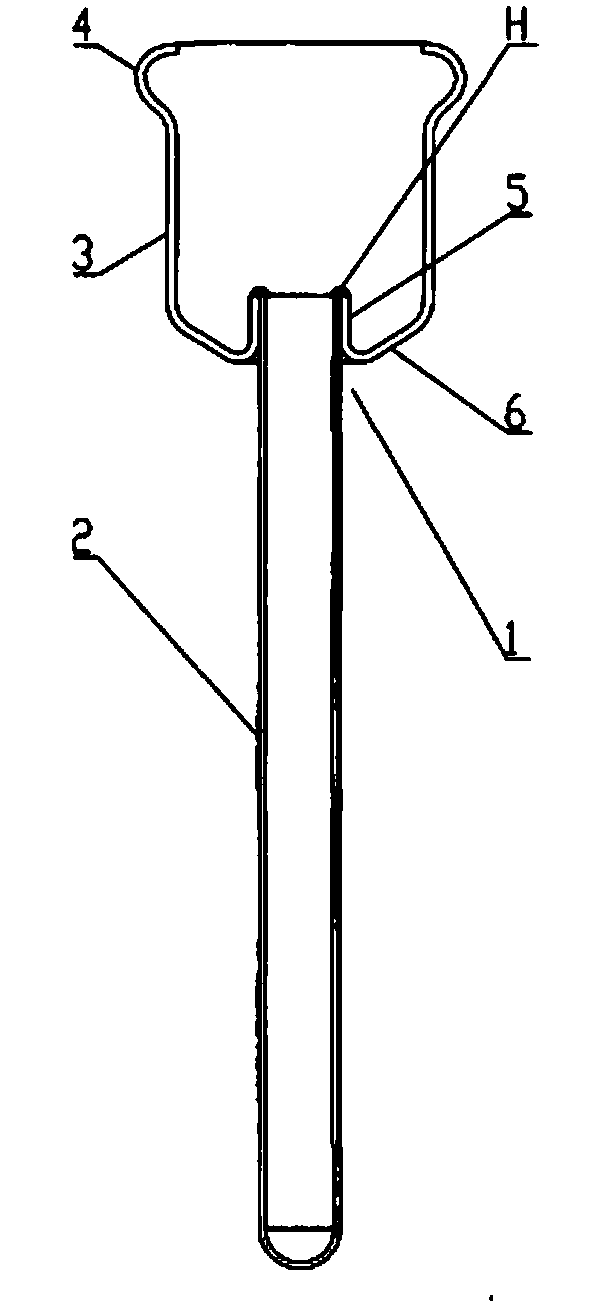

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 Therefore, the metal heat exchange tube device 1 of the present invention is provided with a special-shaped tube head 6; and a heat exchange tube body 2 with one end blocked. The special-shaped tube head 6 can be a corrosion-resistant metal integral part (which can be made by metal drawing and other processing techniques). Stainless steel material is selected), a locking convex ring 4 is provided on the special-shaped tube head, and a sealed straight neck tube 3 is provided under the locking convex ring 4. In the present invention, a straight neck short tube 5 ( figure 1 , figure 2 ); Or, turn inward under the sealed straight neck tube 3 to form a straight neck short tube 5 ( image 3 , Figure 4 ), the heat exchange tube body 2 is connected to the straight neck short tube 5.

[0034] Such as figure 1 , image 3 As shown, the special-shaped tube head 6 is connected to the heat exchange tube body 2 through the straight nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com