Pneumatic tire

一种充气轮胎、轮胎的技术,应用在充气轮胎的增强层、轮胎零部件、车轮等方向,能够解决轮胎总重量大等问题,达到防止脱层损坏、增强弯曲刚度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be discussed with reference to the following drawings.

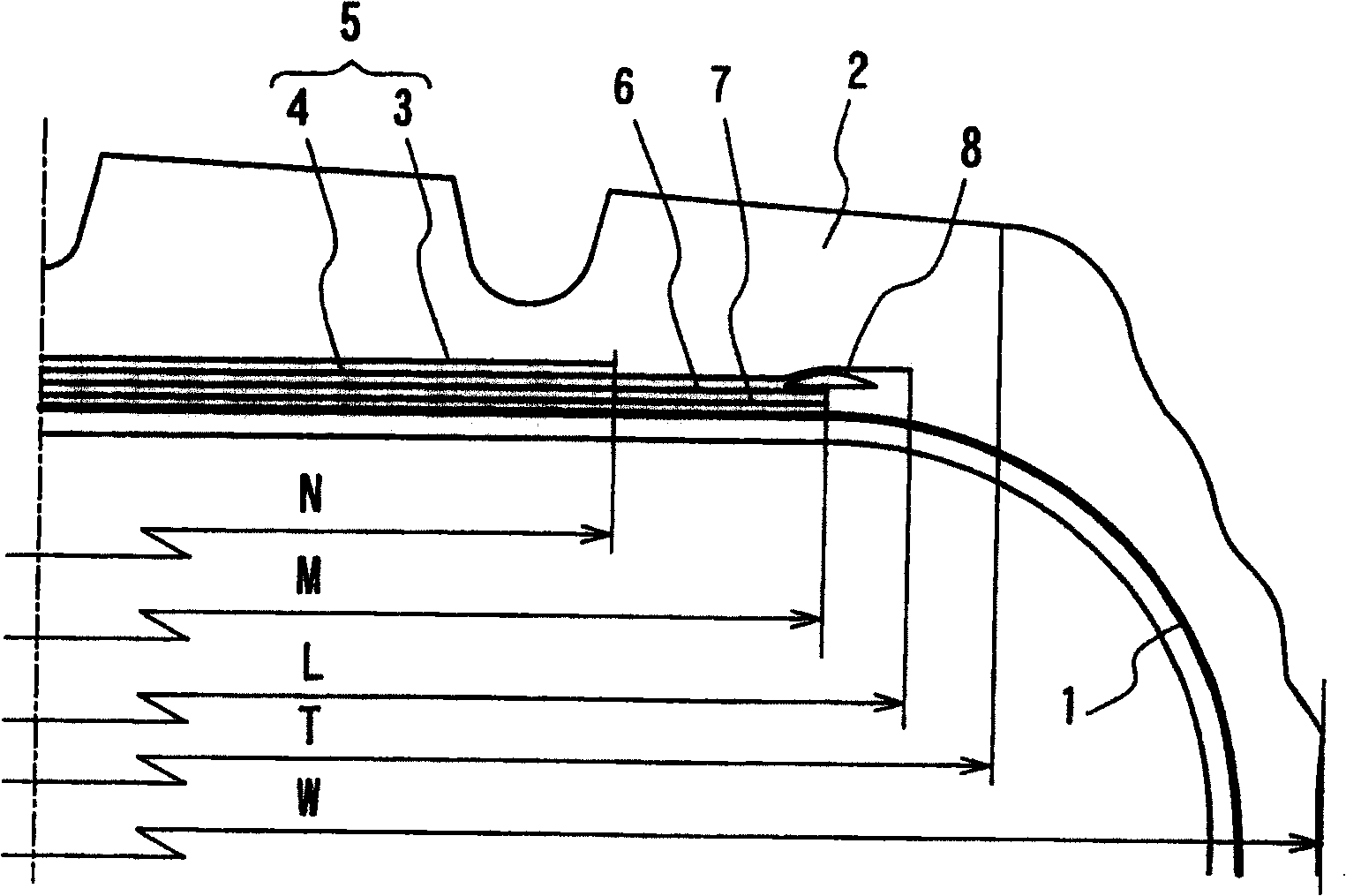

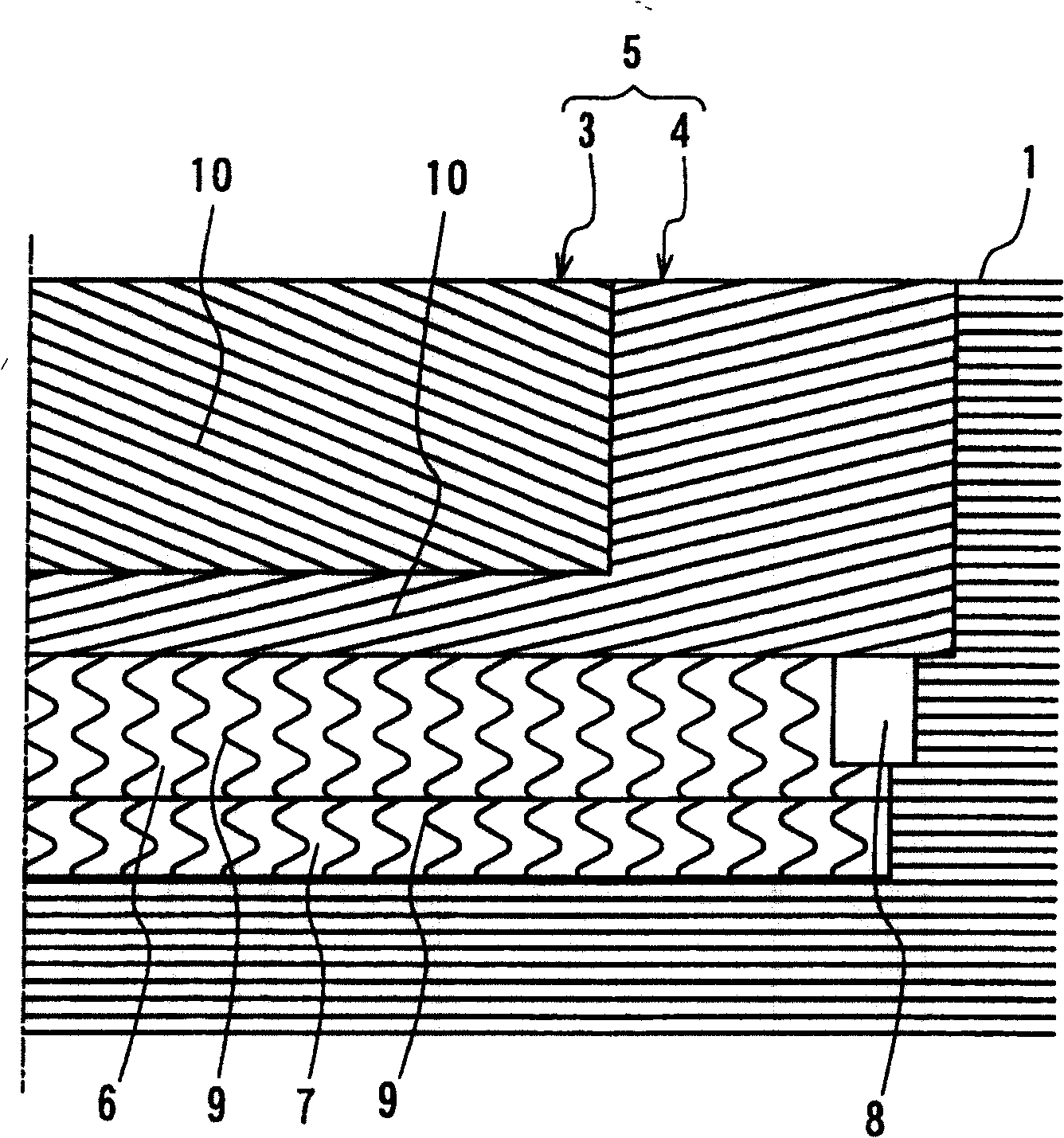

[0030] figure 1 is a transverse sectional view of a tread portion in a half tire according to an embodiment of the present invention. In the drawings, reference numeral 1 is a carcass, and reference numeral 2 is a tread rubber arranged at the outer peripheral side of a crown portion of the carcass.

[0031] A belt 5 comprising two belt layers 3, 4 is arranged between a carcass 1 and a tread rubber 2 extending annularly between bead cores not shown, while two circumferentially reinforcing layers 6 , 7 are arranged in the vicinity of the inner peripheral side of the belt layer 5 . Preferably, a buffer rubber layer 8 with a thickness of 0.5-2.5 mm is interposed between the side end of the circumferential reinforcement layer 7 and the belt layer 4 .

[0032] The width L of the belt layer 4 located on the inner peripheral side is 80-90% of the tire section width W, the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com