Involute and straight claw type rotor structure for oilless vacuum pump

An oil-free vacuum pump and rotor structure technology, applied in the field of involutes, can solve problems such as large vibration and noise, complex processing technology, and short service life, and achieve the goals of reducing vibration and noise, having a long application history, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

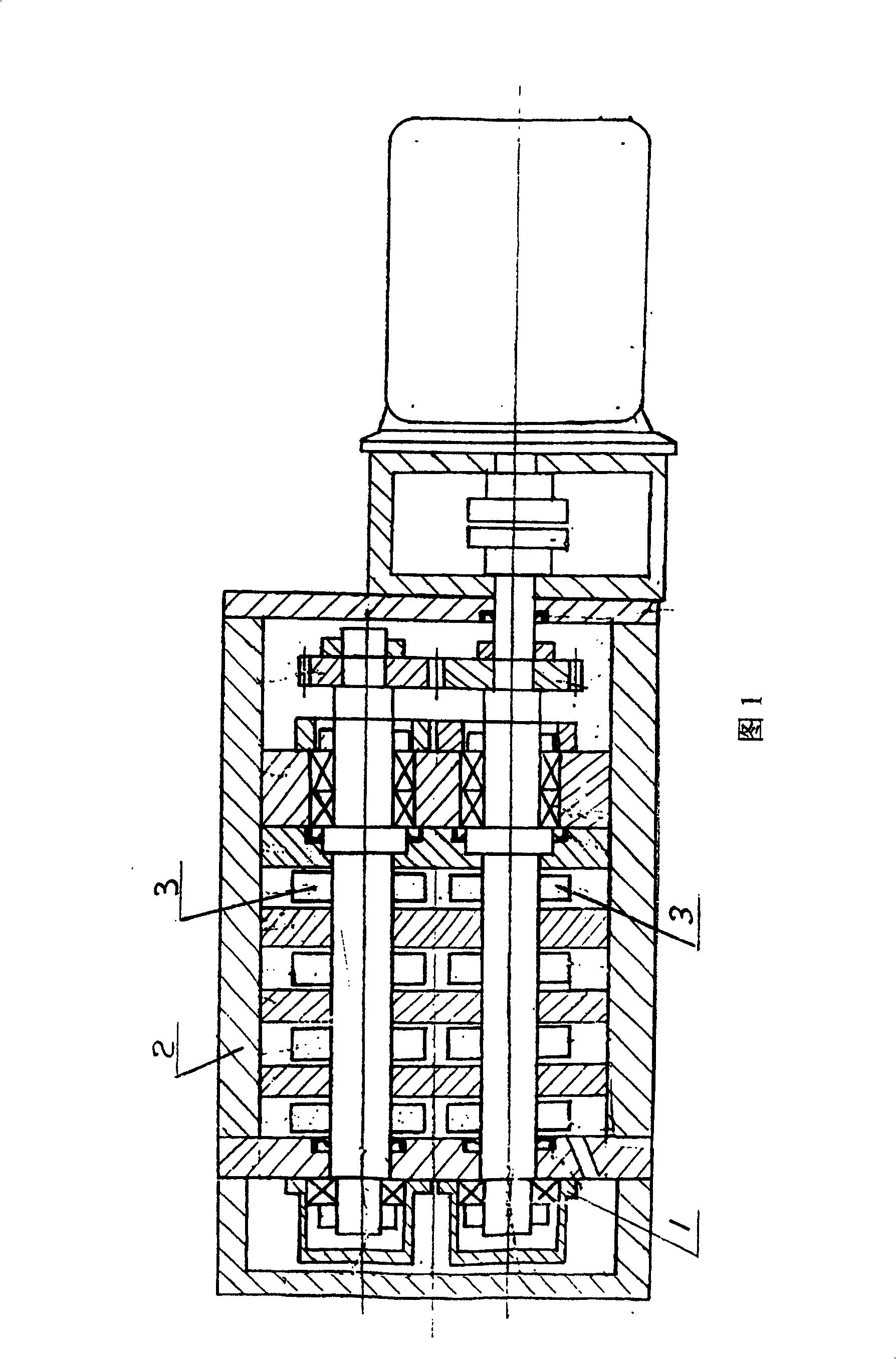

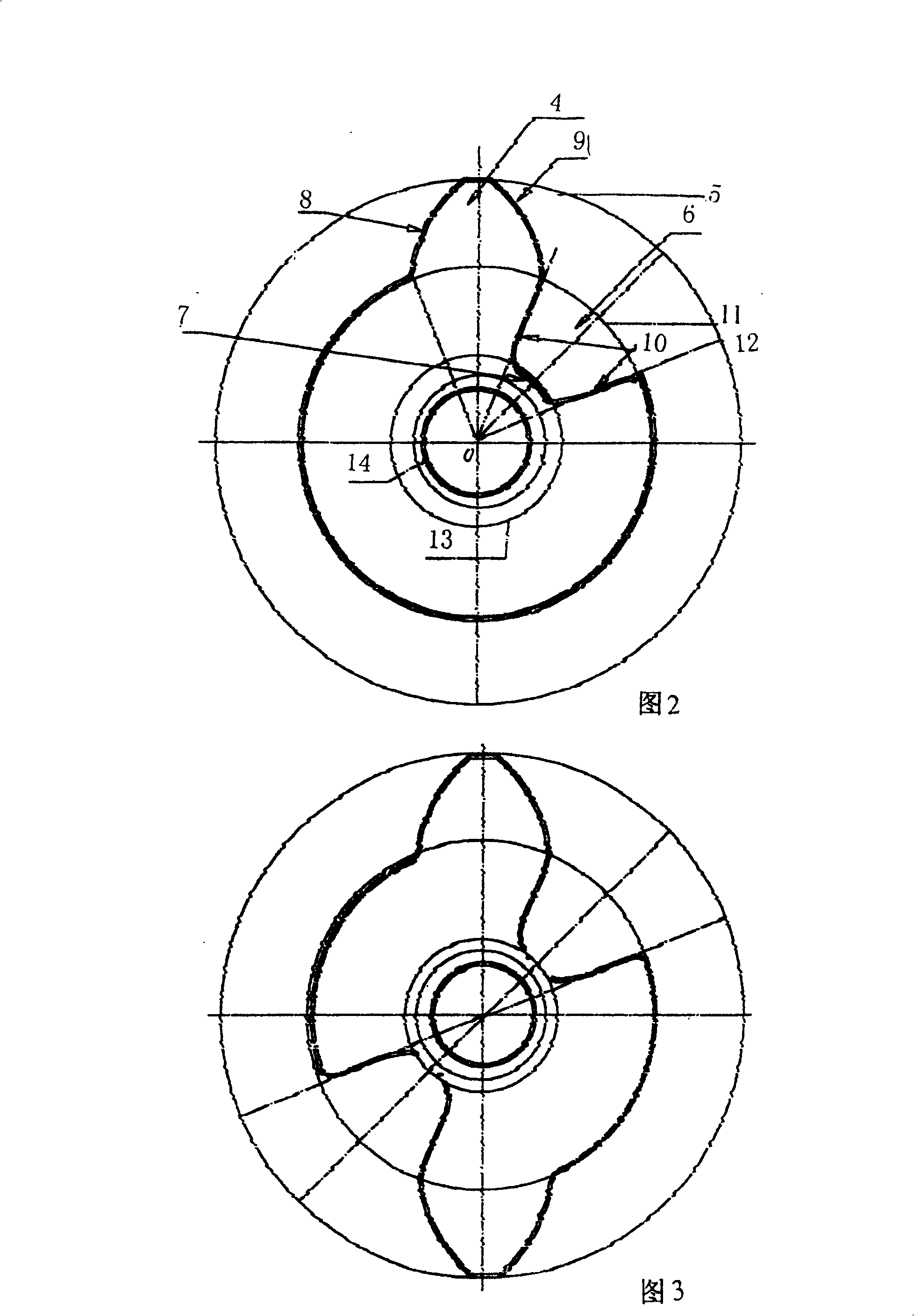

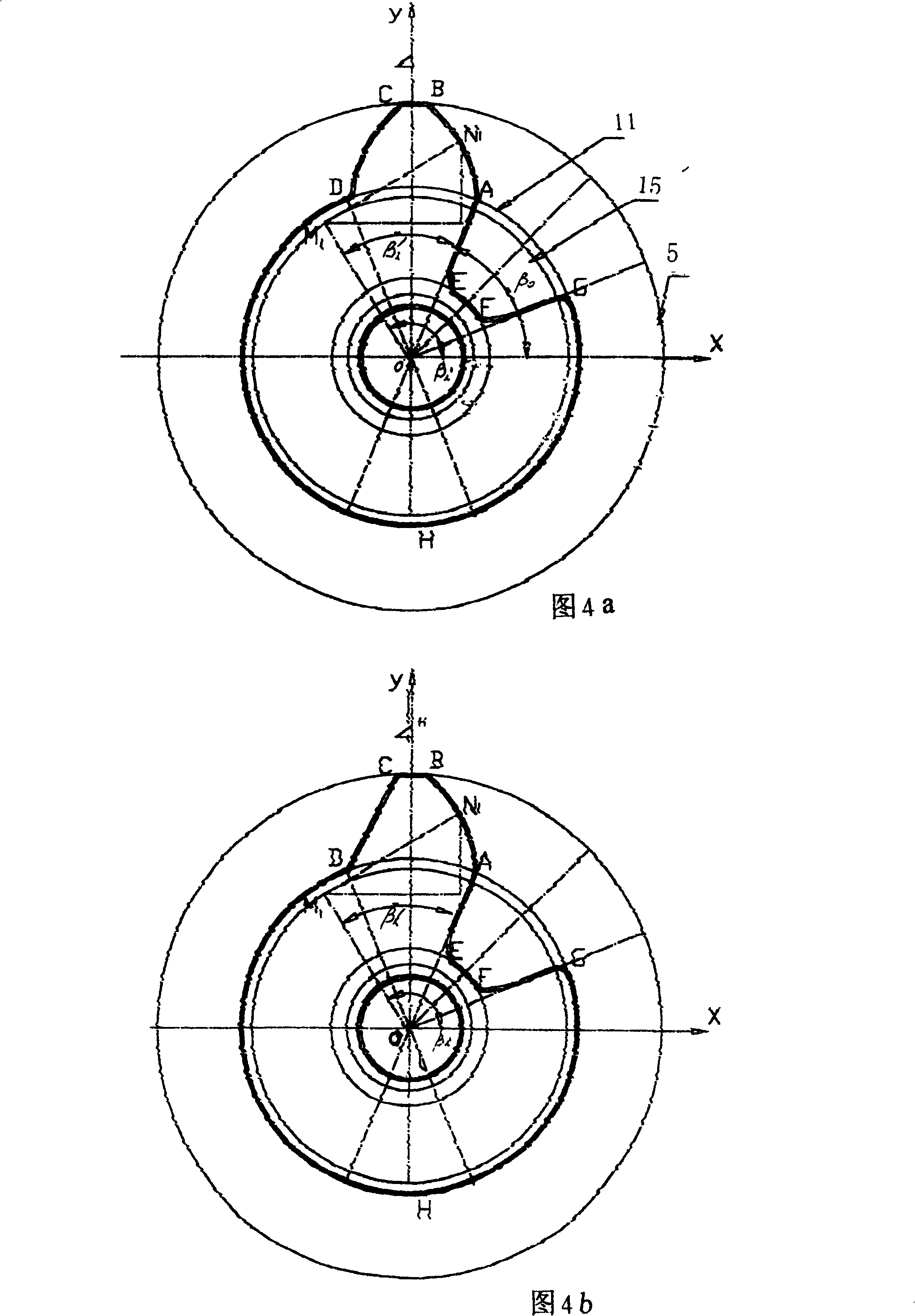

[0029] From Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5 An example is given: an involute and linear claw-type rotor structure for an oil-free vacuum pump, mainly including a pair of claw-type rotors in a pump body 2 that is cooled by a sealing device 1 and a circulating water channel, and driven by a motor and geared. 3 parts, which are characterized in that each of the vacuum pump chambers contains a pair of suspended claw rotor pairs, and each claw rotor includes a single convex single claw arm 4 that is equally distributed in position and phase, and each single claw arm 4 are all accompanied by an inner concave claw groove 6, and the claws on both sides of the outer convex claw arm 4 are gear involute full-toothed claw arms, and the top surface is a section of the garden arc of the outer circumference of the rotor. Claw groove 6 is that straight line section and claw groove bottom 7 garden arcs constitute, and have used such two claw type rotors in every stage of pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com