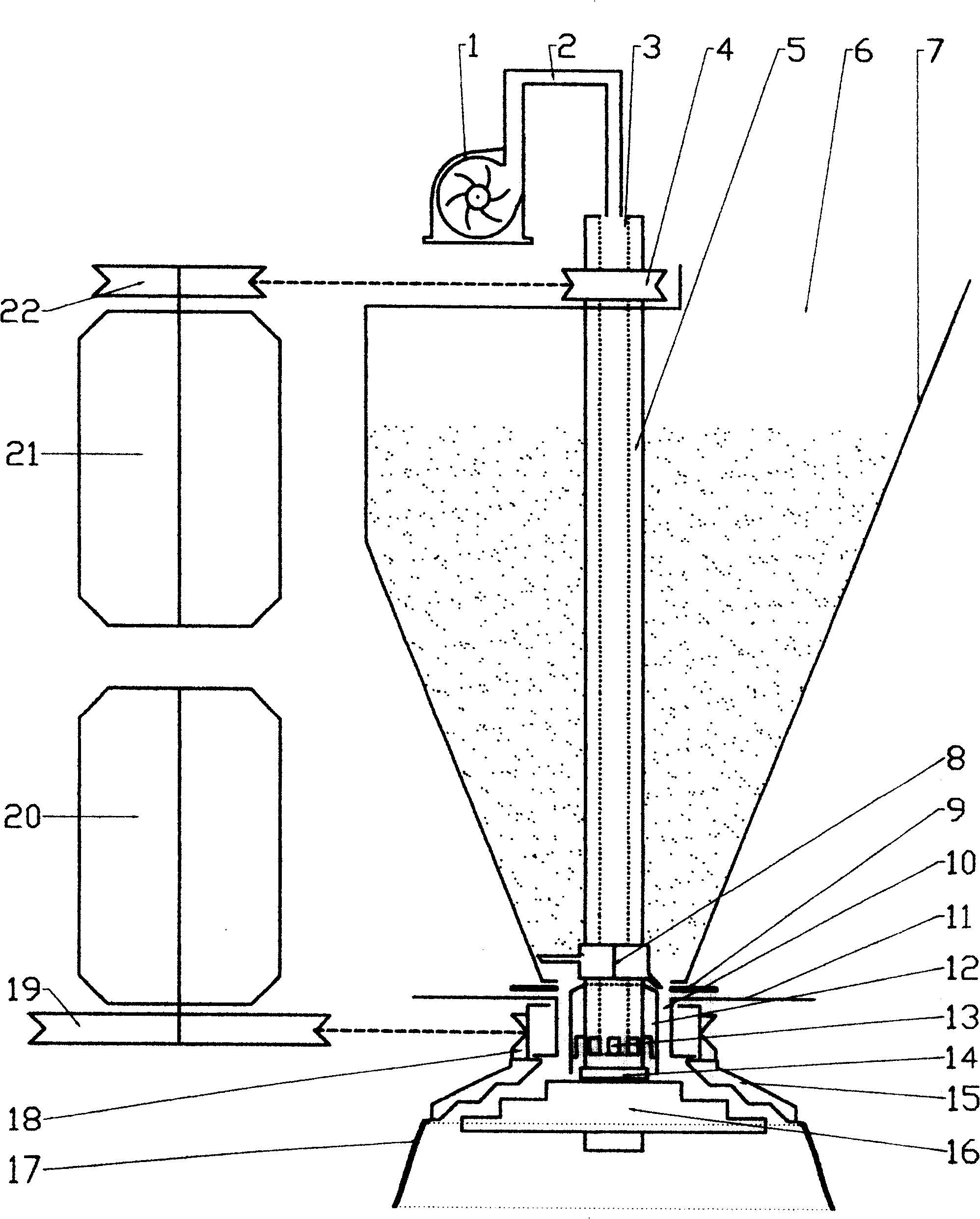

Centrifugal bump type dough kneading machine

A technology of dough mixer and dough bucket, which is applied in the direction of mixing/kneading of horizontal installation tools, which can solve the problems of unstable liquid and dough ratio, waste of manpower and time, ineffectiveness and output, etc., so as to save the power of the motor. The effect of removing, increasing the life, and reducing the time of mechanical action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

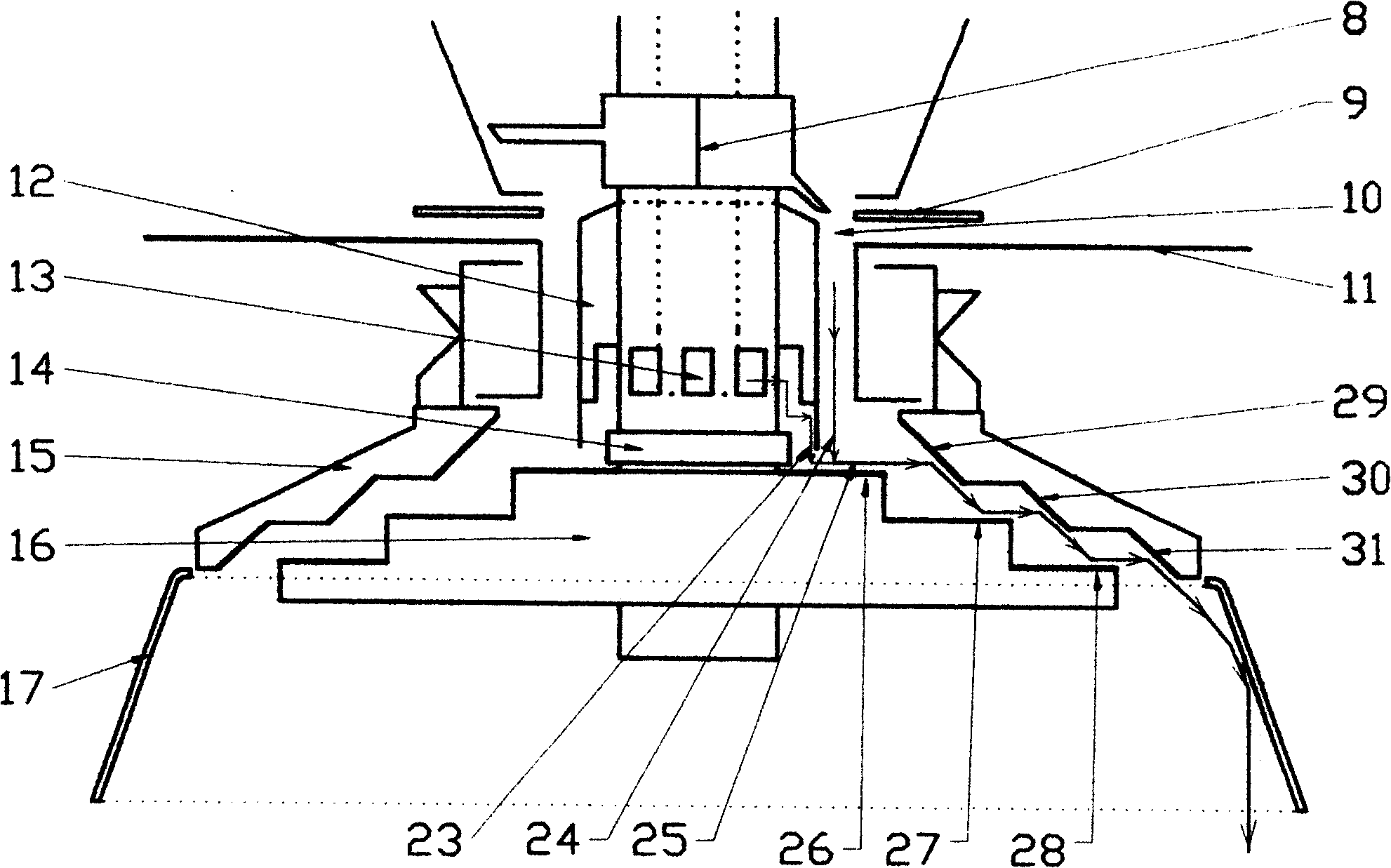

[0014] The liquid is uniformly supplied by the water supply pump 1, passes through the water pipe 2, and enters the pipe shaft 5 from the water inlet 3. The upper half of the pipe axis 5 is hollow tubular, and several water outlet holes 13 are arranged circularly in the middle. A large-diameter sheave 22 is housed on the motor-21, which is connected with the small sheave 4 on the tube shaft 5 by a transmission belt, and drives the tube shaft 5 to rotate clockwise at a high speed. The liquid entering the tube shaft 5 is discharged from the water outlet hole 13 , generates centrifugal force with the rotation of the tube shaft 5 , and moves outward along the liquid lead wire 23 and hits the inner wall of the water cover 12 . The water cover 12 is a cylindrical metal sleeve with a stepped inner wall, which is sleeved on the top of the water outlet 13 of the pipe shaft 5, and the big mouth is downward to cover the water outlet 13 and the water retaining plate 14. After the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com