Delayed fracture prevention method for steel structure and steel structure manufacturing method

A manufacturing method and steel structure technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of delayed damage prevention, delayed damage, and toughness reduction of ultrasonic vibration that have not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

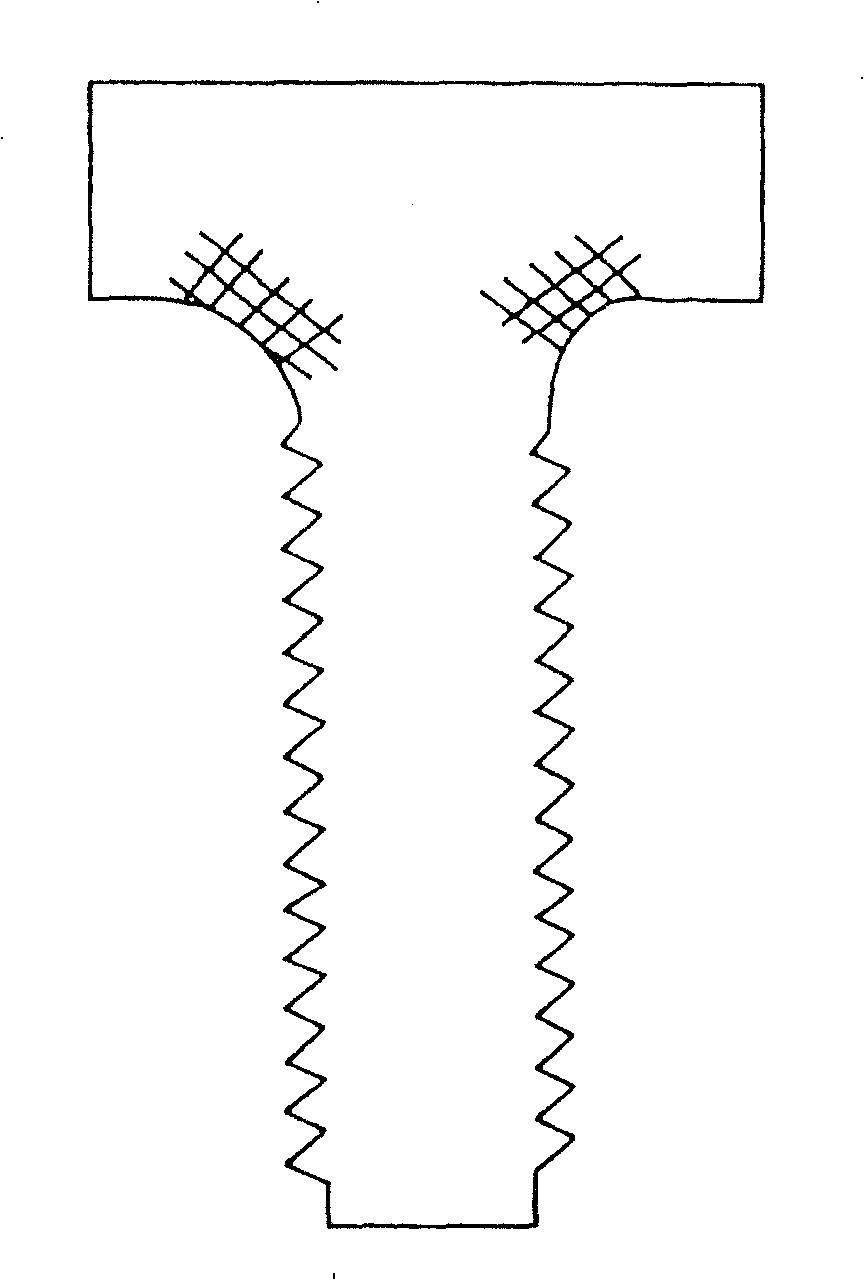

[0028] figure 1 An example in which the delayed failure prevention method of the present invention is applied to a high tension bolt is shown.

[0029] For example, if 1000N / mm 2 If the level of high tension bolts acts on repeated loads, fatigue damage will occur.

[0030] The starting point of this fatigue failure is the area called "fish eye". In this area, due to the internal stress located around the inclusions, the hydrogen present in the steel concentrates around the inclusions, and the local damage resistance deteriorates. Crack formation under small repeated stresses.

[0031] This phenomenon is generally 800N / mm 2 The phenomenon shown in the above high-strength steel materials, however, in welded joints containing a large amount of hydrogen, sometimes even 600N / mm 2 The intensity level of the level also causes problems.

[0032] In steel materials, there are many inclusions, and there are inclusions that form the starting point of fish eyes and inclusions that do...

no. 2 Embodiment

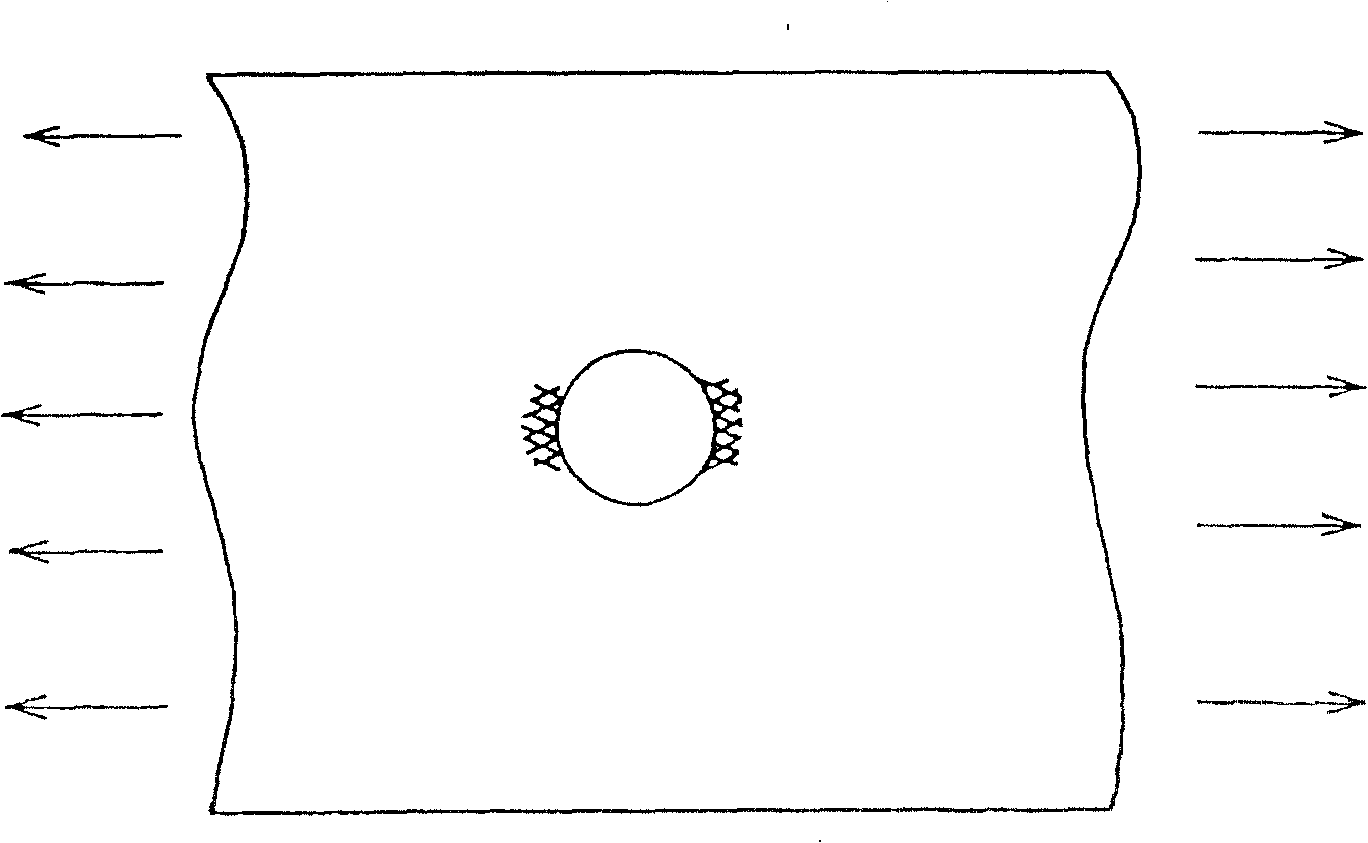

[0038] figure 2 Examples are shown of steel sheets to which the method for preventing delayed failure of the present invention is applied to tensile stress.

[0039] For example, there is a tensile stress of 800N / mm in the action 2 level steel plate, provided with figure 2 In the case of openings as shown, stress concentration occurs at the edge of the opening indicated by the lattice pattern, and hydrogen concentrates at the inclusions where the stress concentration exists as in the first embodiment, thereby deteriorating the local fracture resistance. , Even under the action of small repeated stress, cracks still occur and fish eyes are formed.

[0040] So, in figure 2 In this method, ultrasonic impact treatment is performed on the edge of the opening at the position indicated by the grid pattern, which is impacted with an ultrasonic vibration terminal with a diameter of 1 to 5 mm at the front end. The surrounding area of the TiN precipitates with high internal stre...

no. 3 Embodiment

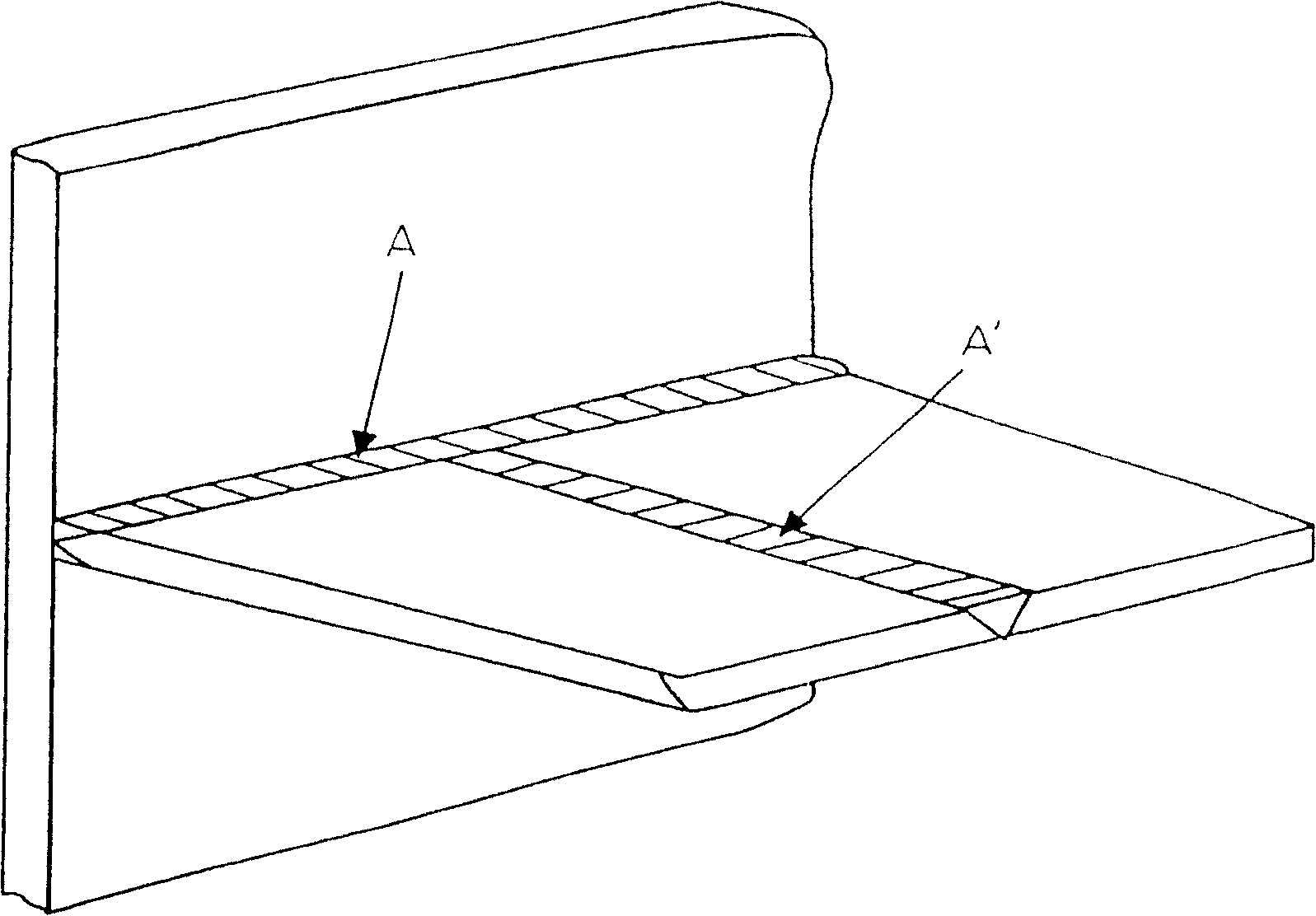

[0042] image 3 An example in which the method for preventing delayed failure of the present invention is applied to an intersection of a plurality of welding lines is shown.

[0043] For example, in welded structures such as ship hulls, such as image 3 As shown, a portion where a plurality of welding lines of A and A' intersect occurs.

[0044] Since the heating input of welding overlaps, the intersection of the plurality of welding lines becomes the highest residual stress, and the stress concentration is remarkable.

[0045] If tensile stress acts on the stress-concentrated portion, hydrogen will concentrate in the surrounding inclusions, and similar to the first and second examples, the local fracture resistance will deteriorate, and cracks will still occur even under small repeated stress , forming a fisheye.

[0046] Figure 4 to represent image 3 A detailed view of the intersection of the welding lines.

[0047] exist Figure 4 In this method, an ultrasonic sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com