Universal carrying device

A carrying device and a general-purpose technology, which is applied in packaging, transportation and packaging, and packaging of fragile items, etc., can solve problems such as excessive materials, inability to reduce packaging consumables, and insufficient effective range of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

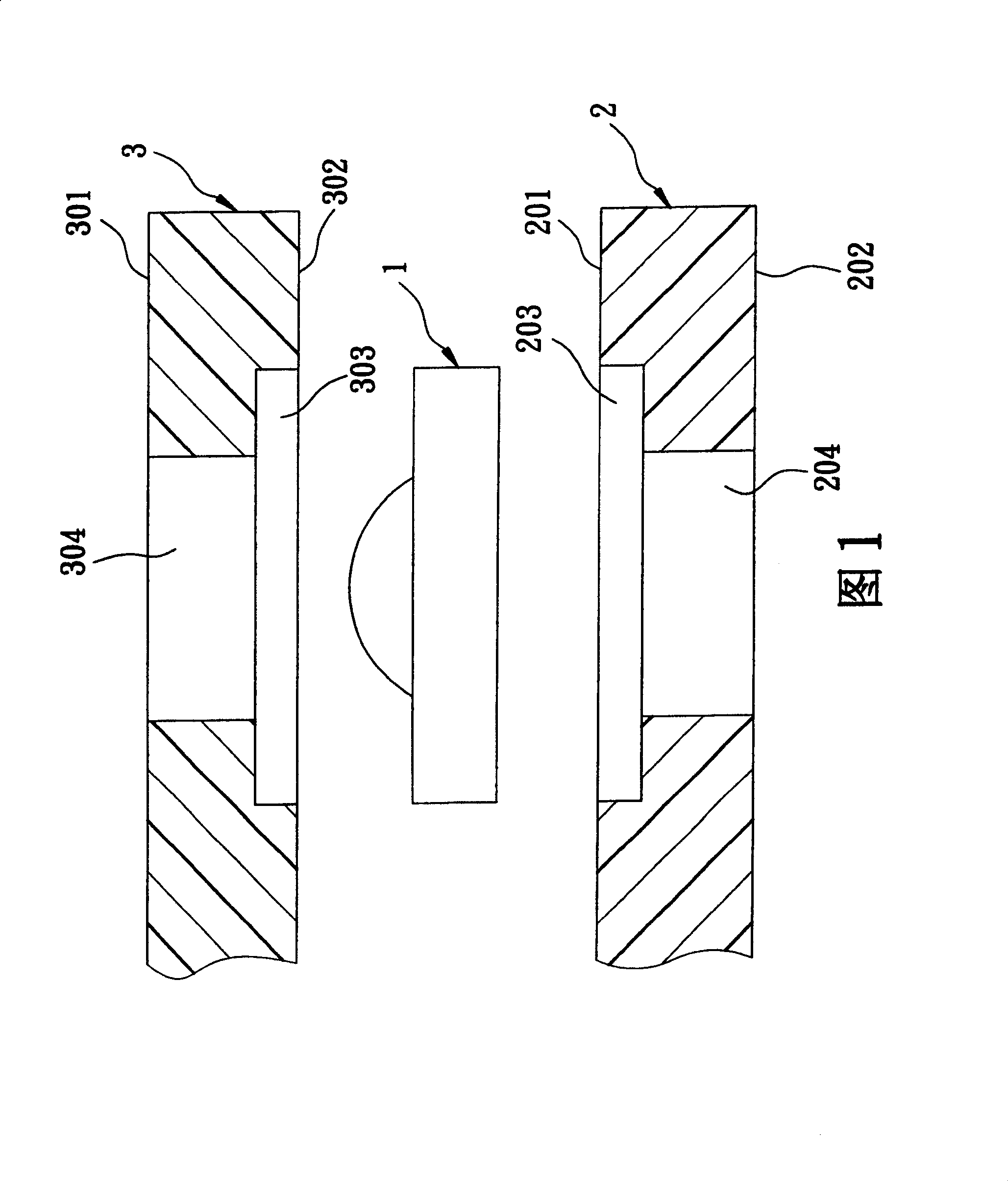

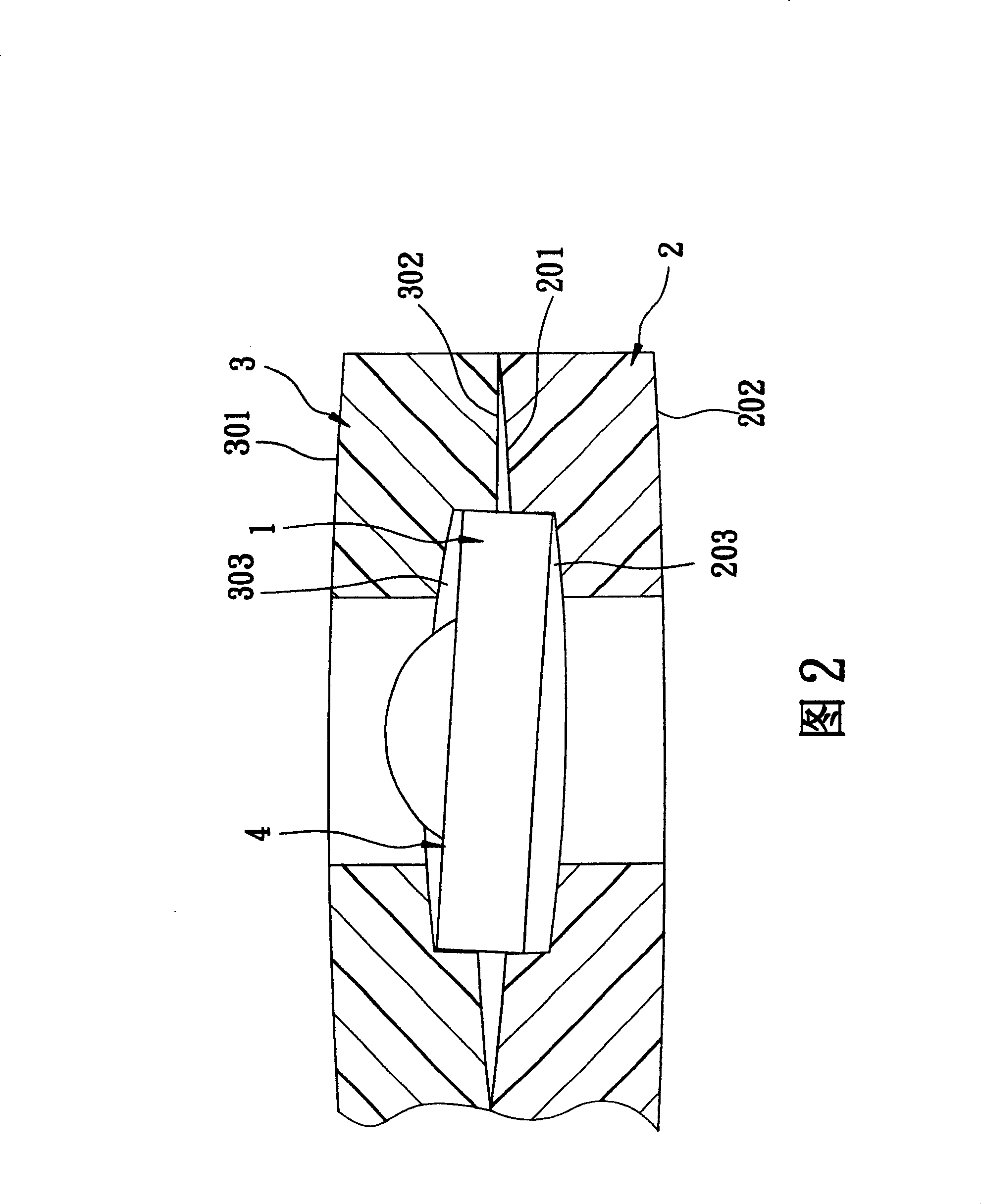

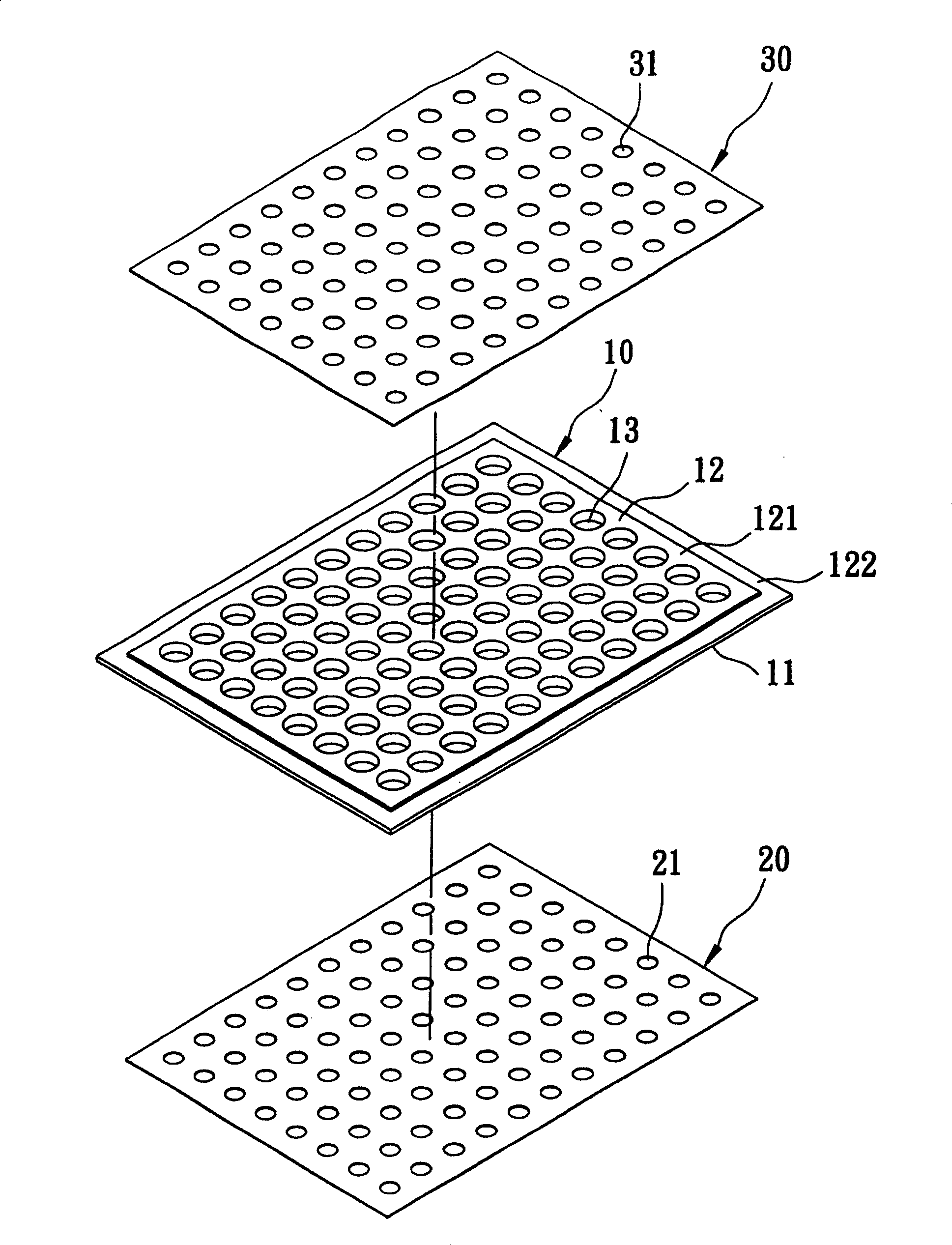

[0020] Such as image 3 As shown in Fig. 4, the preferred embodiment of the general-purpose carrying device of the present invention is suitable for accommodating a plurality of optical lenses 100, each of which has an outer diameter D1 and a light effective circle diameter smaller than the outer diameter D1 D2, and the carrying device includes a base body 10, a first positioning piece 20 detachably fixed on the base body 10, a set opposite to the first positioning piece 20 and is detachably fixed The second positioning piece 30 on the base body 10 .

[0021] The substrate 10 is made of polycarbonate material (PC) into a rectangular plate shape, and has a first surface 11, a second surface 12 opposite to the first surface 11, and a plurality of penetrating through the first and second surfaces. The receiving holes 13 on the surfaces 11 , 12 are defined to each have an inner diameter d1 greater than the outer diameter D1 of the optical lens 100 . The peripheral edges of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com