Projector with micro lens

A projector and micromirror technology, applied in the field of micromirror projectors, can solve the problems of strong graininess of the picture and insufficient fineness of the picture, and achieve the effect of fine picture and improved fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

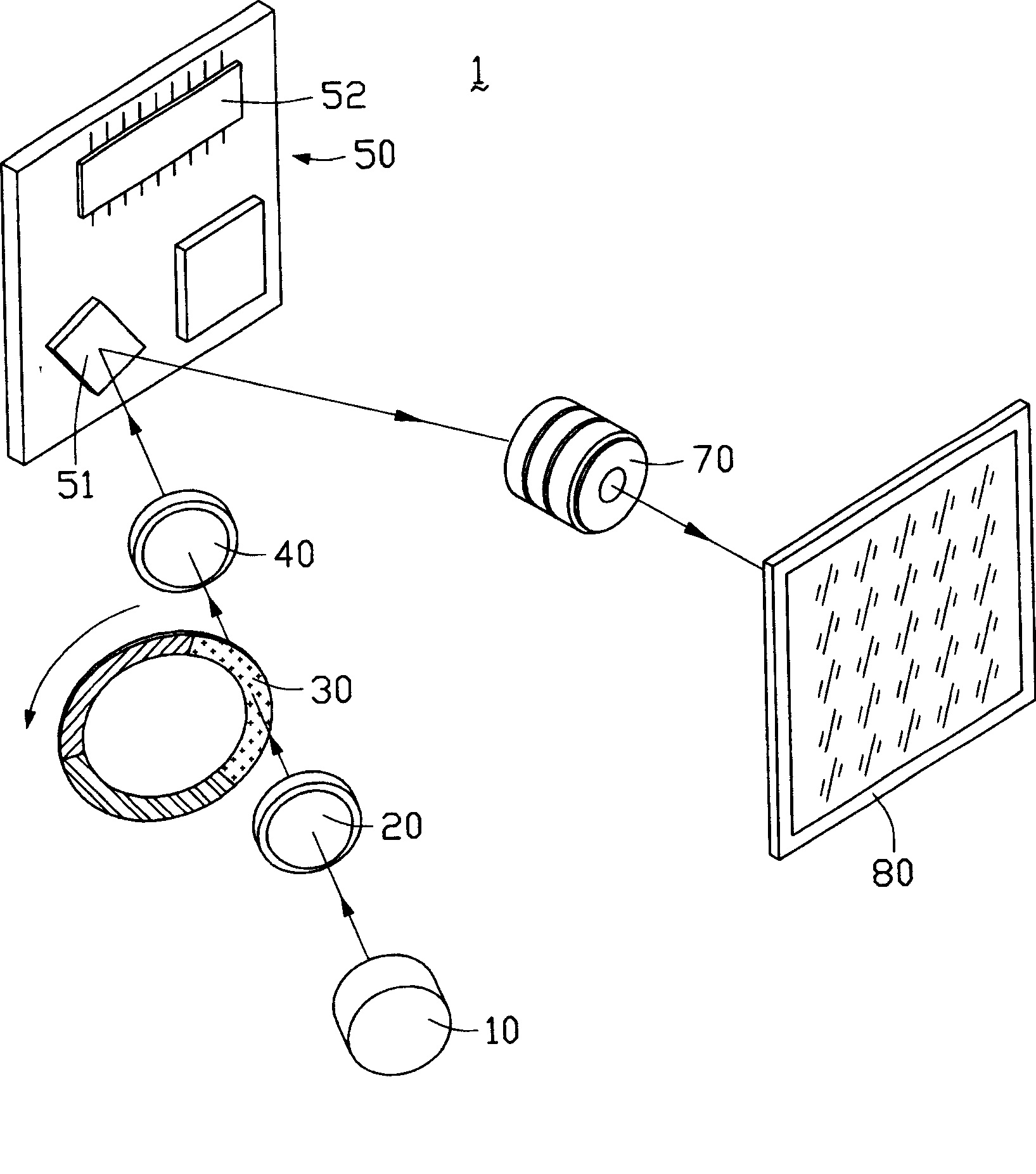

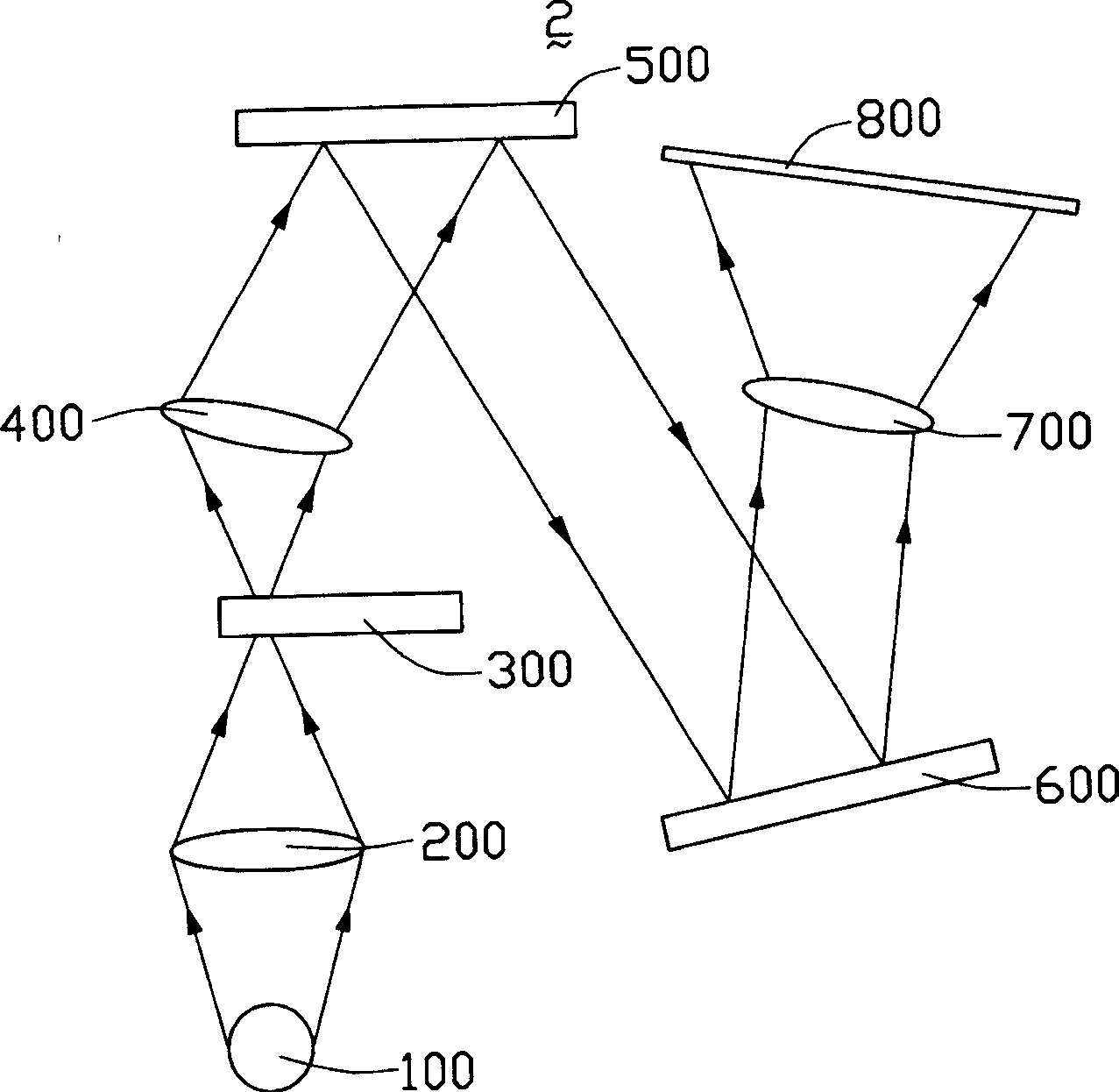

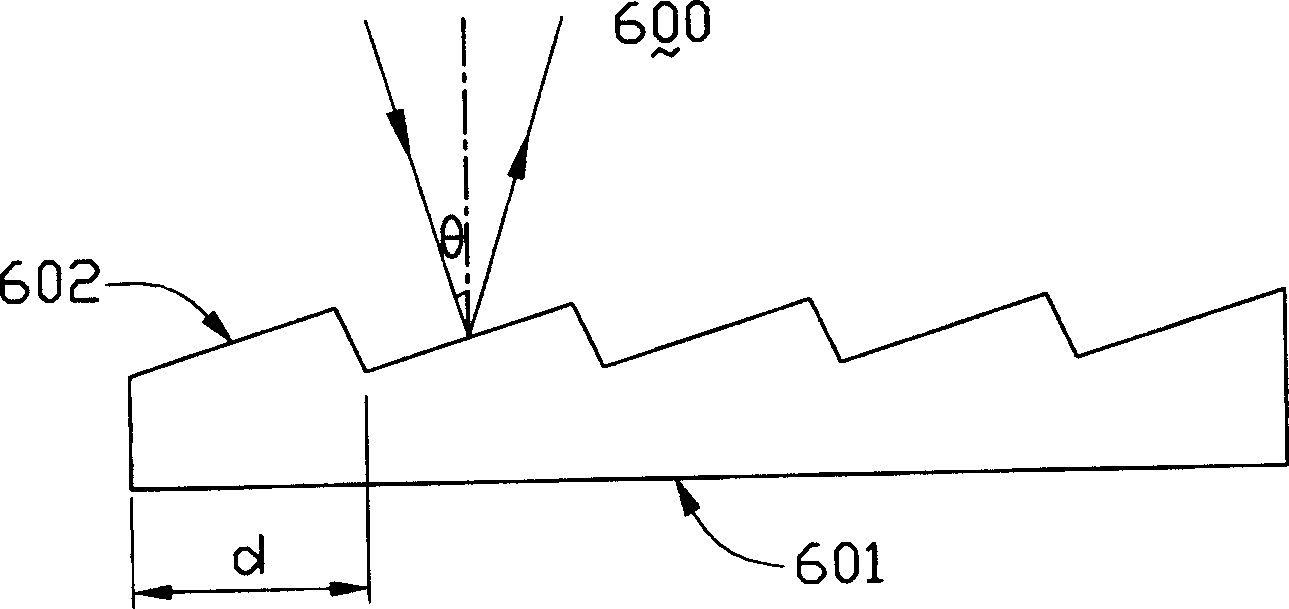

[0012] see figure 2 , is a schematic plan view of the micromirror projector of the present invention. The micromirror projector 2 of the present invention includes a light source 100 , a converging lens 200 , a color wheel 300 , a trimming lens 400 , a micromirror chip 500 , a diffraction component 600 and a projection component 700 . The color wheel 300 includes three color regions of red, green and blue, and can rotate at high speed. The micromirror chip 500 includes a micromirror component (not shown) with a plurality of micromirrors and a processor (not shown). The plurality of micromirrors receive signals from the processor to perform rapid switching actions.

[0013] The light emitted by the light source 100 is converged to the color wheel 300 through the converging lens 200, and the high-speed rotation of the color wheel makes the passing light turn into three monochromatic colors of red, green and blue in a very short time. The light is incident on the micromirror p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com