Method for preventing liquid fluctuating of continuous casting peritectic steel crystallizer

A liquid level fluctuation and crystallizer technology, which is applied in the field of preventing liquid level fluctuations in continuous casting molds, can solve problems such as liquid level fluctuations, achieve the effects of eliminating liquid level fluctuations, facilitating popularization and application, and reducing casting slab quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

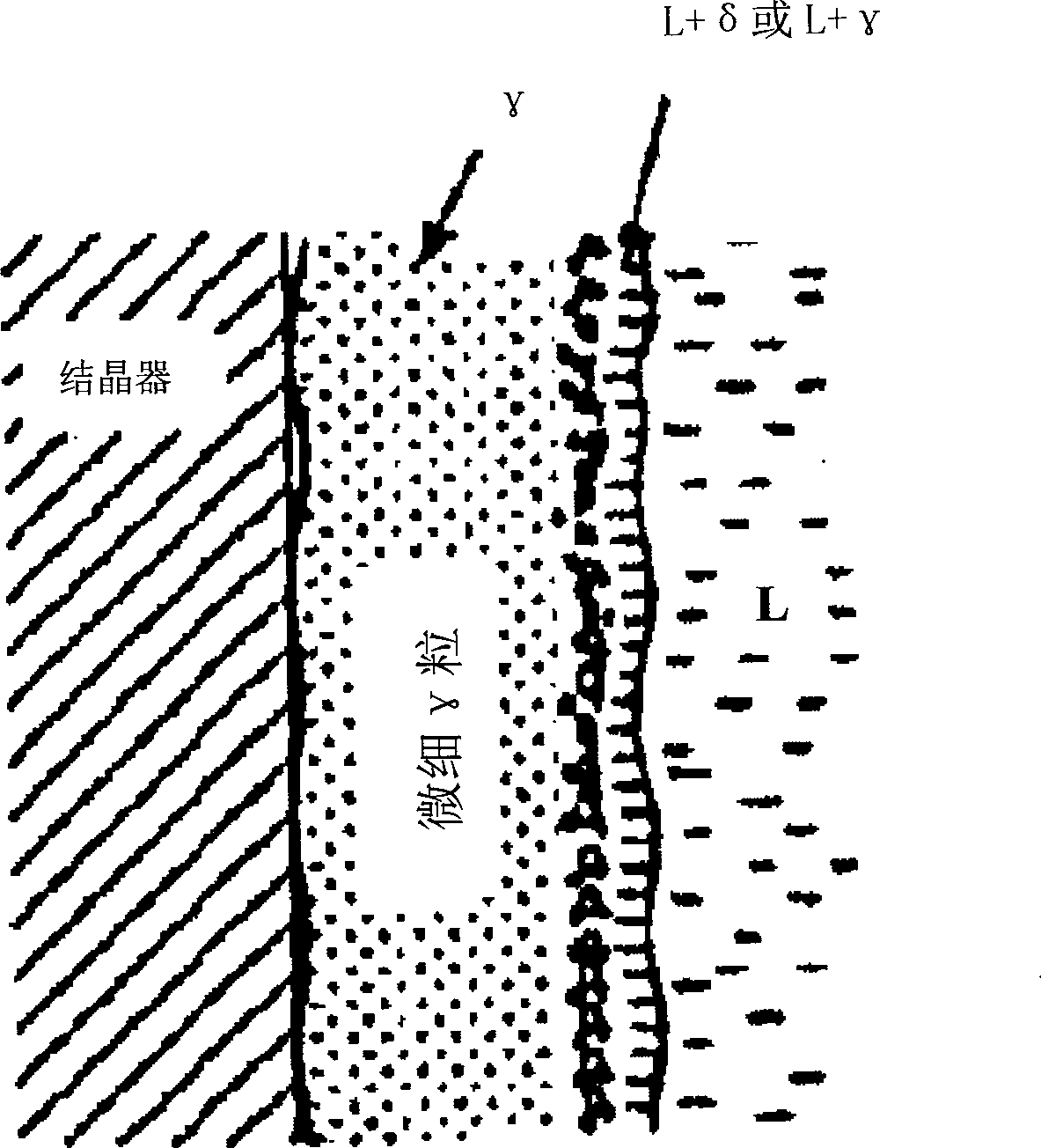

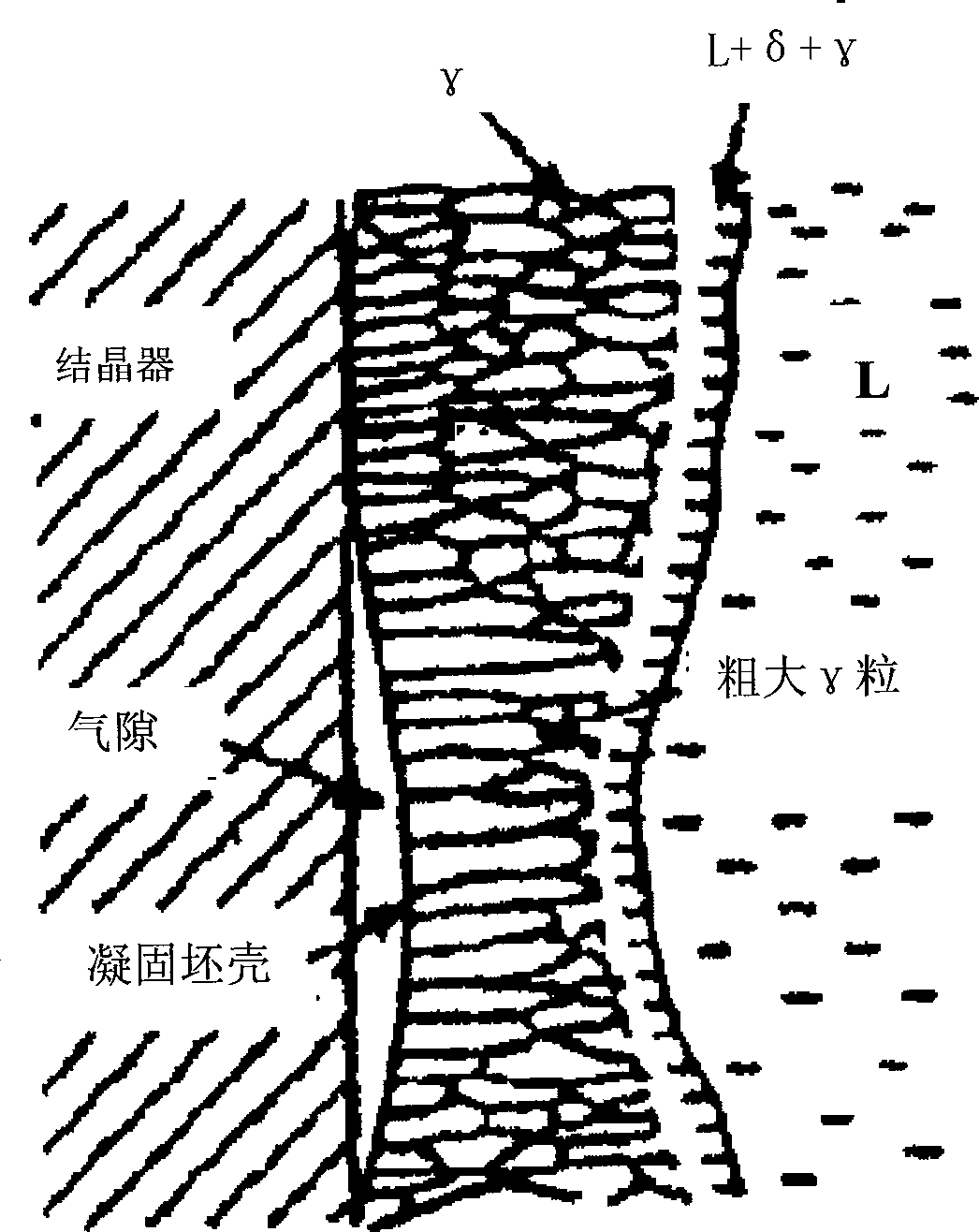

[0032] The inhomogeneity of the primary shell in the mold is the root cause of the fluctuation of the liquid level of peritectic steel. Therefore, ensuring the uniformity and stability of the primary shell of the mold is the key to solving the problem. Both theory and practice have proved that weak cooling and slow cooling of the crystallizer can effectively control the uneven growth of the shell.

[0033] The straight arc type casting machine is designed as a 900mm long straight plate mold, the water flow rate of the wide side is 3600l / min, and the temperature difference between the inlet and outlet water is about 5°C. The cooling intensity of the billet in the mold is obviously higher than that of the original full arc type casting machine. One of the reasons why the peritectic steel liquid level rarely fluctuates in the original full-arc casting machine. Therefore, by calculating and referring to the water volume of the 900-long full-arc caster mold, this embodiment provide...

Embodiment 2

[0041] The only difference between this embodiment and embodiment 1 is that the specific composition of the peritectic steel mold flux is (wt%): SiO 2 : 25.25, Fe 2 o 3 : 1.07, CaO: 35.06, Al 2 o 3 : 2.18, MgO: 3.23, C: 3.18, H 2 O: 0.15,K 2 O: 0.55, Na 2 O: 8.82, F: 6.92, R: 1.17, and the rest are impurities. After testing, the melting point of mold flux with this composition is 1145°C, and the viscosity (Pa.s) is 0.158.

[0042] A large number of experiments have proved that the proportion of mold flux in this embodiment can completely eliminate liquid level fluctuations during casting of peritectic steel.

Embodiment 3

[0044] The only difference between this embodiment and embodiment 1 is that the specific composition of the peritectic steel mold flux is (wt%): SiO 2 : 33.49, Fe 2 o 3 : 0.85, CaO: 38.5, Al 2 o 3 : 1.82, MgO: 3.48, C: 2.83, H 2 O: 0.42,K 2 O: 0.26, Na 2 O: 9.24, F: 6.53, R: 1.42, and the rest are impurities. After testing, the melting point of mold flux with this composition is 1132°C, and the viscosity (Pa.s) is 0.168.

[0045] A large number of experiments have proved that the proportion of mold flux can completely eliminate the phenomenon of liquid level fluctuation when casting peritectic steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com