A soft blowing method and control device for argon blowing at the bottom of a continuous casting ladle rotary table

A technology of turret and continuous steel casting, which is applied in the field of steelmaking in iron and steel metallurgy. It can solve the problems of easy blockage of breathable bricks, unreasonable adjustment of argon gas flow, and increased cost of refractory materials for ladle lining, so as to reduce the consumption of oxygen for cleaning. and nitrogen consumption, the improvement of non-burning oxygen purge rate, and the effect of reducing slab quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

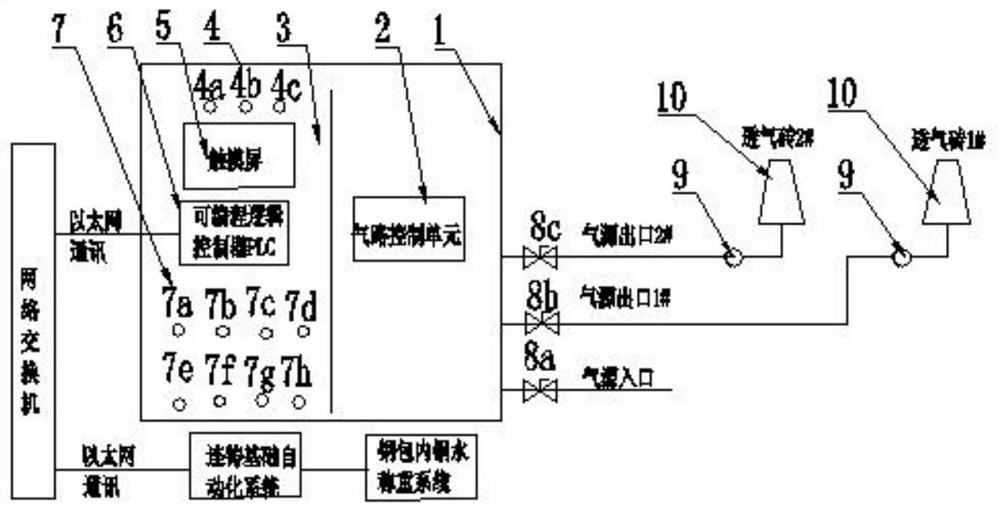

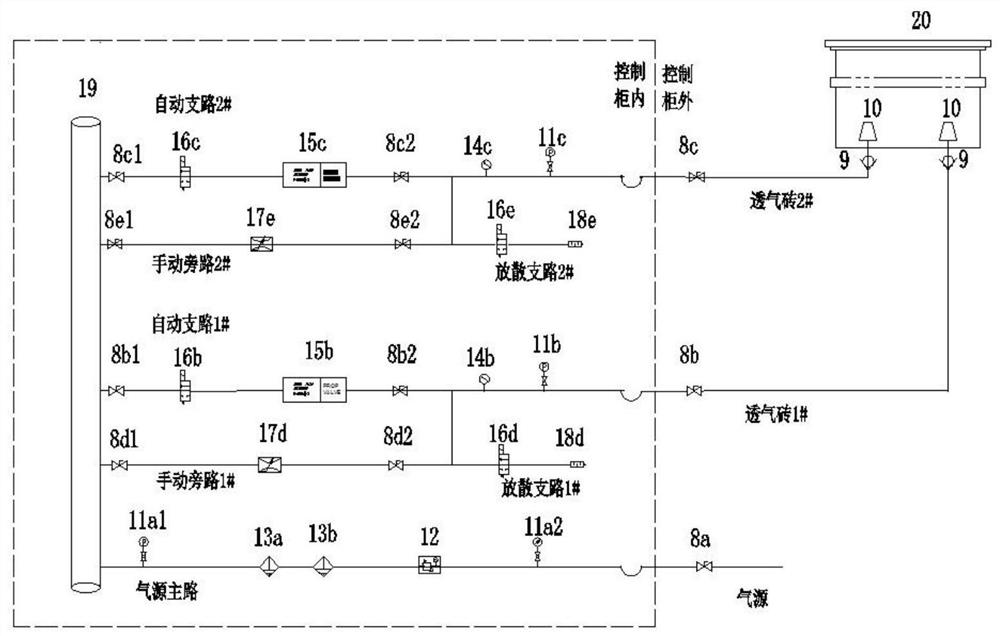

[0096] A control device for blowing argon at the bottom of a continuous casting ladle turret, such as figure 1 , figure 2 As shown, it includes a gas circuit control cabinet 1 and an electrical control cabinet 3. The electrical control cabinet 3 is equipped with a signal light 4, a touch screen 5, a programmable logic controller PLC 6 and a switch button 7, and the gas circuit control cabinet 1 is equipped with a gas circuit control unit. 2. There are first manual ball valve 8a, second manual ball valve 8b, The third manual ball valve 8c connects the gas source inlet to the gas source, and the gas source outlet 1# and the gas source outlet 2# communicate with the ventilation brick 1# and the ventilation brick 2# through the quick joint 9 respectively.

[0097] The signal light 4 is used for prompting or alarming, including a red light 4a, a yellow light 4b and a blue light 4c, wherein, the red light 4a-an alarm for blockage of the ventilation brick or low pipeline pressure, ...

Embodiment 2

[0143] As described in Example 1, a soft blowing method and control device for argon blowing at the bottom of a continuous casting ladle turret, the difference is:

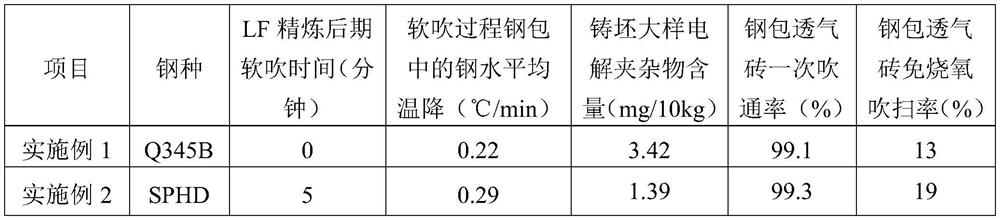

[0144] It is used for 130tLF refining ladle casting to produce low carbon steel SPHD, and the soft blowing time in the post-stage of LF refining in the prior art is 10min

[0145] (1) Select the automatic soft blowing mode, select the type of breathable brick: SPHD is a middle-end steel grade with inclusion control requirements, choose automatic soft blowing mode B: shorten 50% of the soft blowing time in the late stage of LF refining in the existing technology, that is, 5min , transferred to the continuous casting ladle turret for soft blowing. When the amount of molten steel pouring reaches 40% of the total amount of molten steel in the ladle, that is, 130t×40%=52t, stop argon blowing. The change of the net weight of the molten steel is linearly adjusted, the soft blowing value of the molten steel pouring proces...

Embodiment 3

[0155] As described in Example 1, a control device and soft blowing method for argon blowing at the bottom of a continuous casting ladle turret, the difference is:

[0156] It is used for 130tLF refining ladle casting to produce ultra-low carbon steel DC04, and the soft blowing time of the existing technology LF refining stage is 12min

[0157] (1) Select the automatic soft blowing mode, select the type of breathable brick: DC04 is a high-end steel grade with strict inclusion control, select the automatic soft blowing mode C: shorten the soft blowing time of the existing technology LF refining stage by 25%, that is, 3min, transfer Go to the continuous casting ladle turret for soft blowing. When the molten steel casting volume reaches 50% of the total molten steel in the ladle, that is, 130t×50%=65t, stop argon blowing. The change of the net weight is adjusted linearly, the soft blowing value of the molten steel pouring process = the net weight of the remaining molten steel in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com