Brake of high-speed heavy-load vehicle

A vehicle braking and high-speed technology, applied in the direction of brake type, axial brake, friction lining, etc., can solve the problem of low braking deceleration and uneven wear that cannot meet the requirements of high-speed, high-power, and heavy-duty vehicles and other problems, to achieve the effect of decreasing average temperature rise, increasing heat capacity, and increasing effective friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

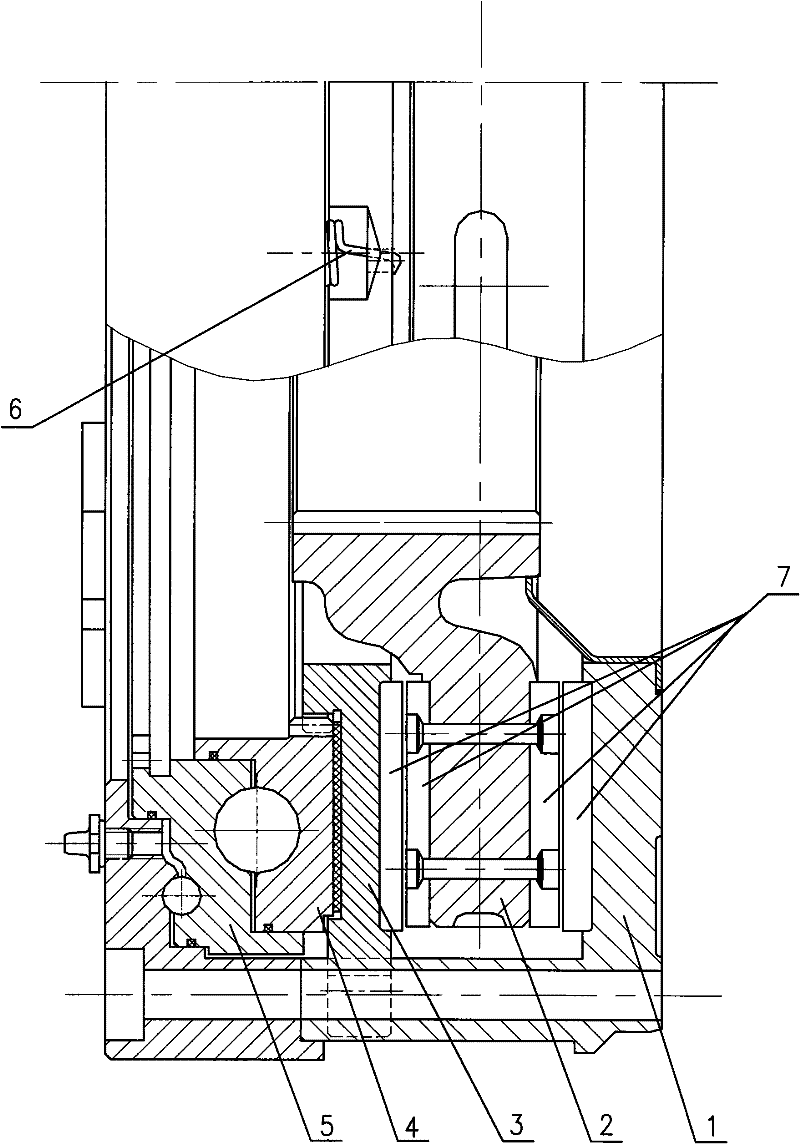

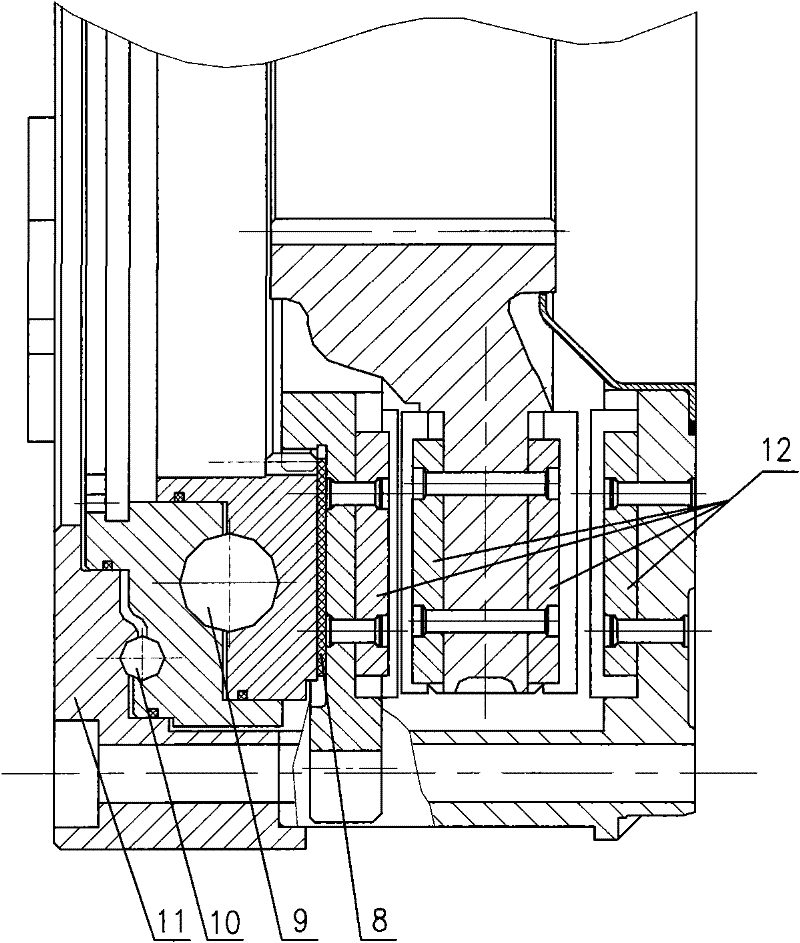

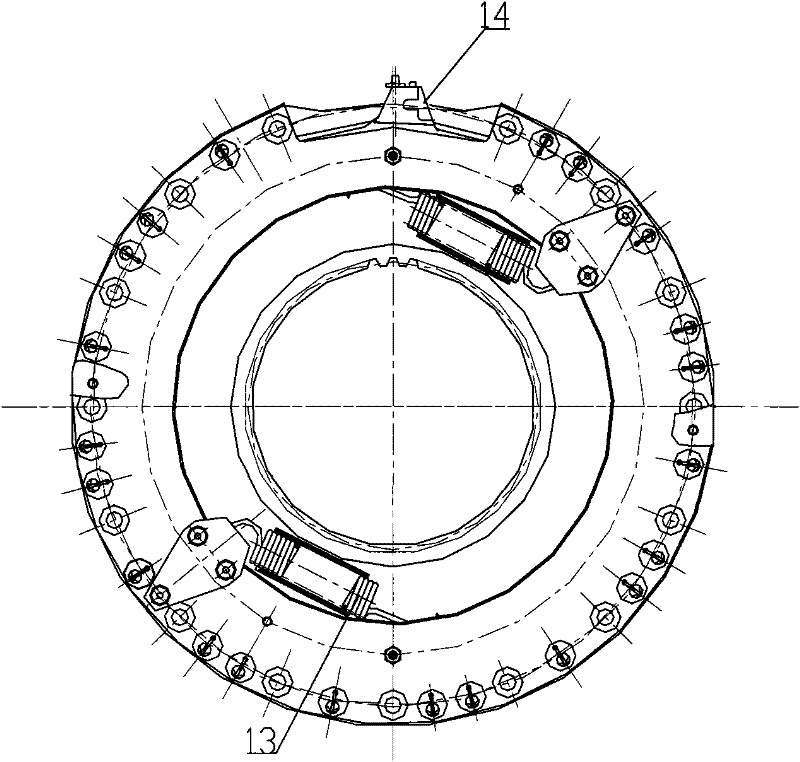

[0026] With reference to the accompanying drawings, in a tracked vehicle, there is a full disc brake on the left and right, located between the output shaft of the integrated transmission device in the engine room and the input shaft of the side reducer. Under the action of the control system and its actuators, it undertakes the work of normal braking, emergency braking and parking braking, and can provide a torque that stops the vehicle from the maximum speed and keeps the vehicle on a slope of 60%. The loading method of the full-disc brake is to press the dynamic and static discs under the action of the control oil through the brake cylinder, and achieve the purpose of deceleration or parking through friction.

[0027] The original installation state of the full-disc brake is the parking state of the brake, so the parking function should be released before the vehicle is started; Operate the brake pedal as required to inject the control fluid of the corresponding brake oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com