Method for improving hot rolling quality of electromagnetic stirring plate blank

An electromagnetic stirring and quality technology, applied in the manufacture of converters, etc., can solve the problems of mold slag involvement defects, increase mold slag emulsification, and mold slag involvement, so as to reduce casting slab quality defects, improve hot rolling quality, Effect of improving slab quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

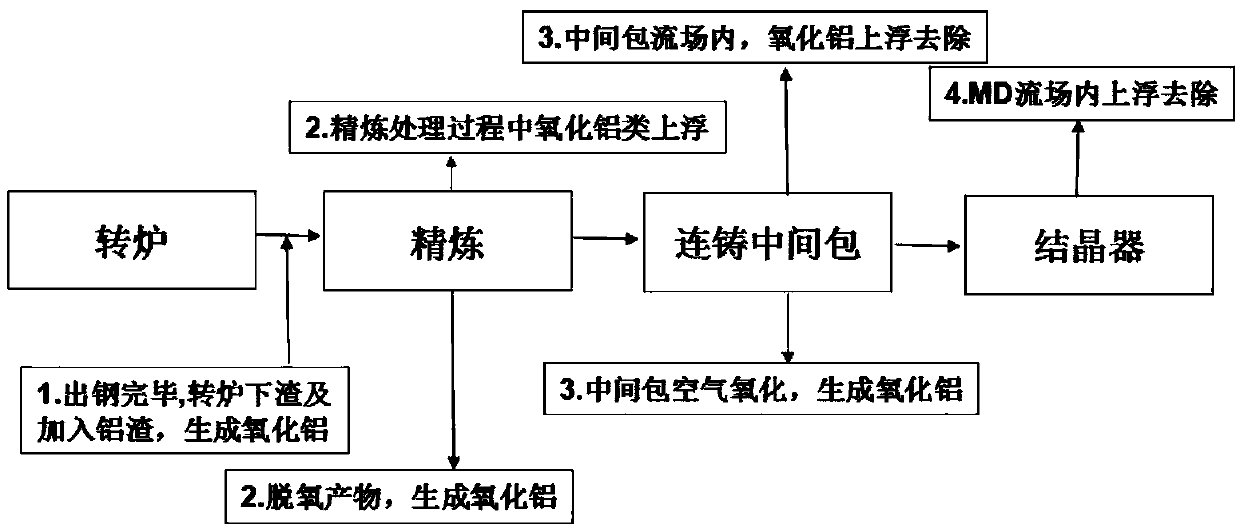

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] For a batch of 300 tons of ladle, the converter stop blowing information is as follows: stop blowing free oxygen 691ppm, stop blowing carbon 400ppm, according to the converter slag volume 1500kg, the converter stop blowing slag composition is as follows:

[0038] Table 1 Converter slag composition (wt%)

[0039] CaOAl 2 O 3

MgO FeOSiO 2

MnO Impurities 46.82.18.120.012.63.9 margin

[0040] Note: During the production process, the total analysis components are less than 100, mainly uncontrollable components, such as loss on ignition and dust.

[0041] In the refining process, the oxygen removal in the molten steel is completed, and a part of the carbon in the molten steel is taken away. About 25% (100ppm) of the carbon in the molten steel is used to deoxidize the refractory materials and auxiliary materials of the molten steel, and the remaining about 75% ( 300ppm) decarburization with free oxygen in molten steel, the decarburization reaction formula is as follows (1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com