Strip steel hot rolling control method

A strip steel and rough rolling technology, which is applied in metal rolling, temperature control, metal rolling, etc., can solve problems such as low hit rate, stacked steel at the head of the strip, unfavorable strip production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

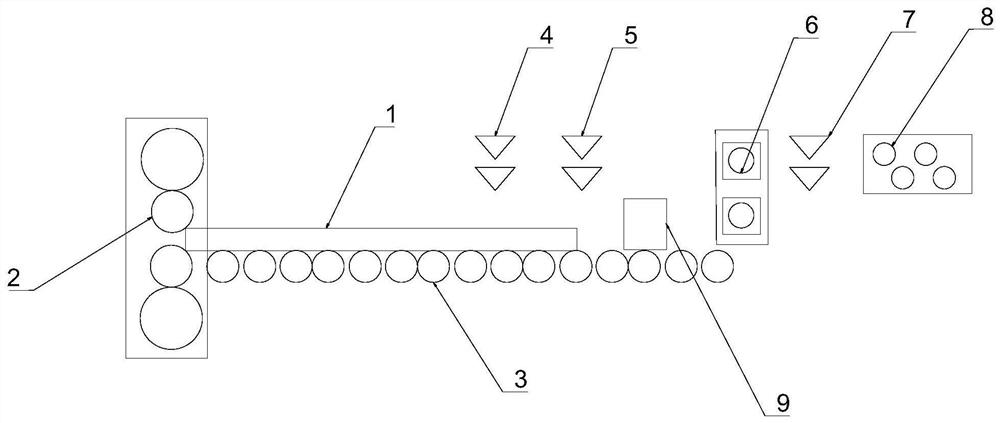

[0035] In order to make those skilled in the technical field of the present invention understand the present invention more clearly, the technical solutions of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

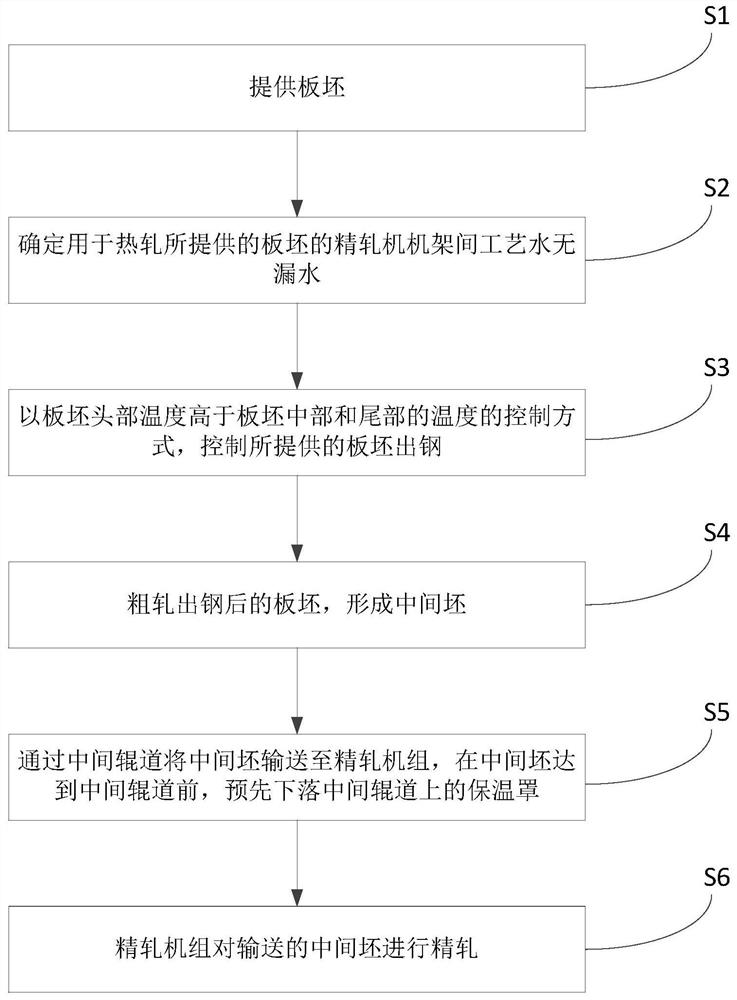

[0036] figure 1 It is a schematic flow sheet of a strip hot rolling method according to an embodiment of the present invention, combining figure 1 , the method includes:

[0037] S1: Provide slab;

[0038] S2: It is determined that there is no leakage of the process water between the finishing mill stands for hot rolling the supplied slab.

[0039] Specifically:

[0040] Before rolling thin strip steel below 2.0mm, use the time when the finishing mill replaces the work rolls to check the process water between the finishing mill stands, including the water sealing effect of the working roll cooling water scraper. If the sealing water is not good, immediately Replace the wiper; also inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com