Method for reducing steel oxidation decarburization and application thereof

A steel and decarburization technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems affecting the performance of steel and changes in organizational structure, achieve obvious economic and social benefits, reduce oxidation and decarburization, and avoid The effect of significant changes in tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1——Steel Type 1 Experimental Results

[0033] In this embodiment, steel type 1 is selected for experimentation, and its composition is (mass%): 0.64C, 0.29Si, 1.00Mn, <0.01Al, 0.022P, 0.009S through chemical analysis, and the balance is iron. The size of the experimental sample is 10mm × 10mm × 6mm, the surface is ground to 800# SiC sandpaper and chamfered and chamfered, ultrasonically cleaned in acetone and then dried for later use. Oxidation experiments were performed using a Thermax 700 thermogravimetric analyzer (with an accuracy of 0.3 μg). This embodiment adopts three kinds of simulated oxidizing atmospheres, and the oxygen partial pressures (oxygen volume concentration in ambient atmosphere) of atmospheres 1, 2 and 3 are respectively controlled below 21%, 4% and 0.1%. Oxygen partial pressure in hot rolling furnace atmosphere.

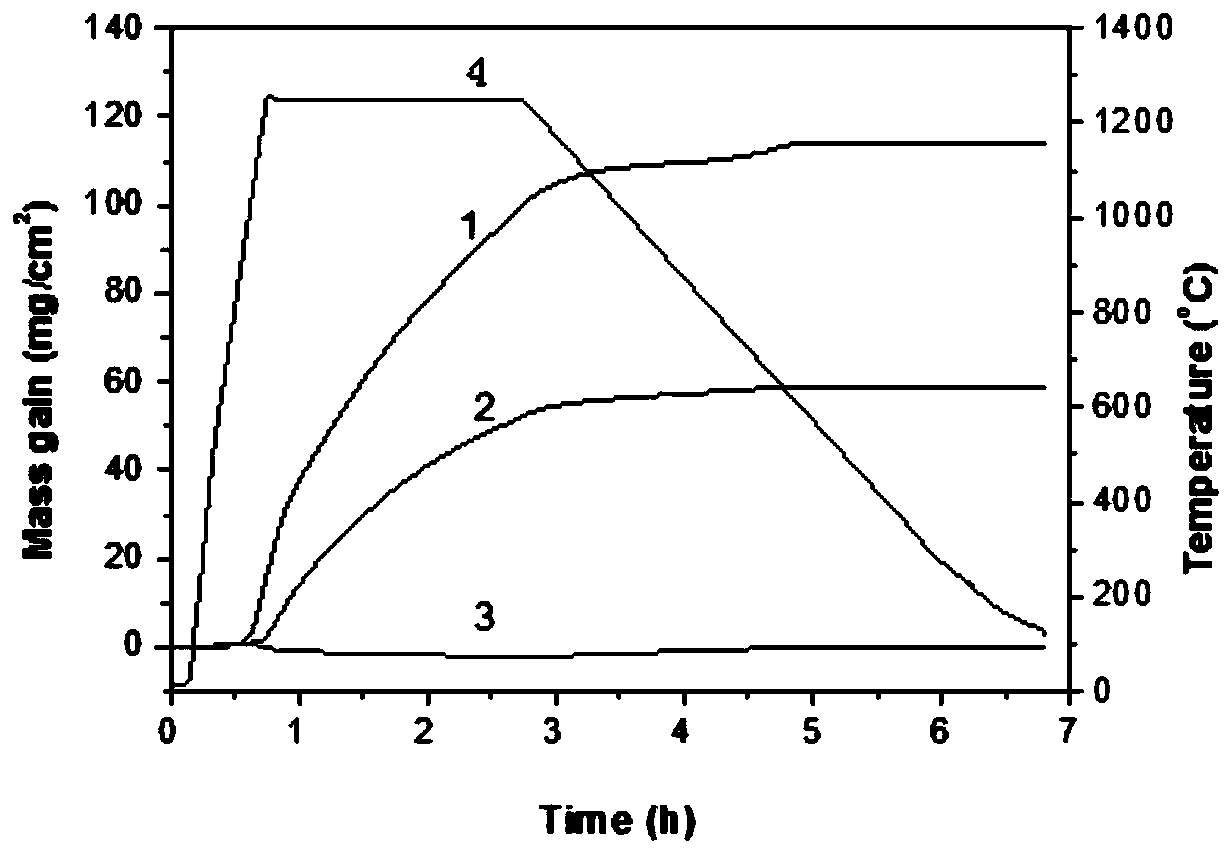

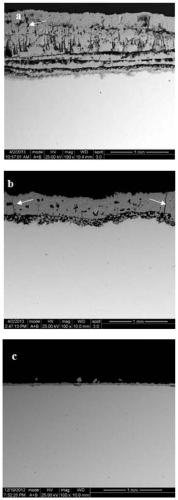

[0034] As shown in Figure 1(a), curves 1, 2, and 3 are the oxidation kinetics curves of steel type 1 in atmospheres 1, 2, an...

Embodiment 2

[0041] Embodiment 2——steel type 2 experimental results

[0042] For further validation, the effect of atmosphere control on the oxidation decarburization of steel grade 2 was studied. The chemical analysis of steel type 2 is (mass%): 0.44C, 0.23Si, 0.75Mn, 0.022P, 0.005S, and the balance is iron. The sample size, surface grinding treatment, cleaning method and oxidation test are the same as steel type 1. This embodiment also adopts the three control atmospheres in Embodiment 1.

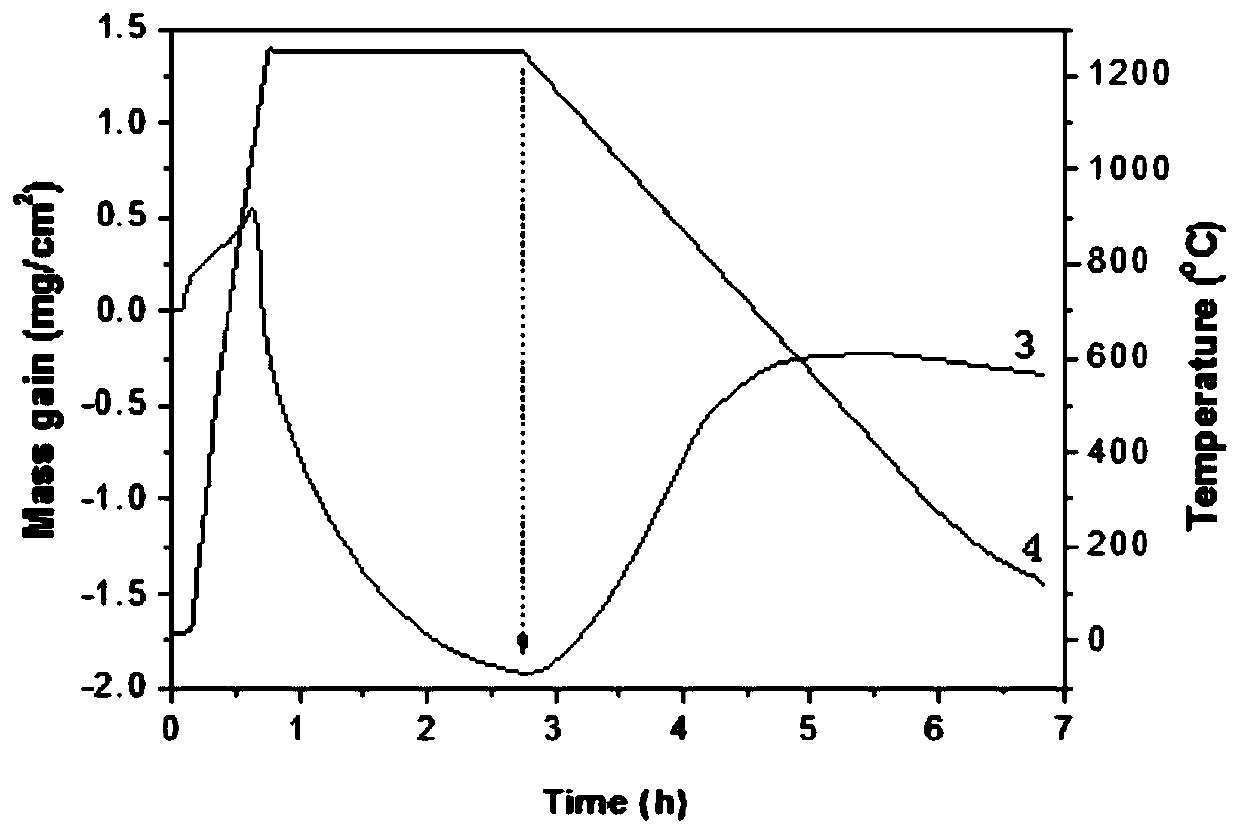

[0043] As shown in Figure 7(a), curves 1, 2 and 3 are the oxidation kinetics curves of steel type 2 in atmospheres 1, 2 and 3 at a constant temperature of 1250 °C for 2 h, and the oxidation weight gain rate of the steel decreases significantly in turn, And like steel type 1, curve 3 also has some slight oxidation weight loss phenomenon. As shown in Figure 7(b), curve 3 is enlarged, and the oxidation weight loss is more clearly visible. However, compared with steel type 1, although the cooling proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com