High temperature rotary lifting mechanism

A lifting mechanism and lifter technology, which is applied in the field of high-temperature rotary lifting mechanism, can solve the problems of lifting device paralysis, material falling, damage, etc., and achieve the effect of avoiding hidden troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

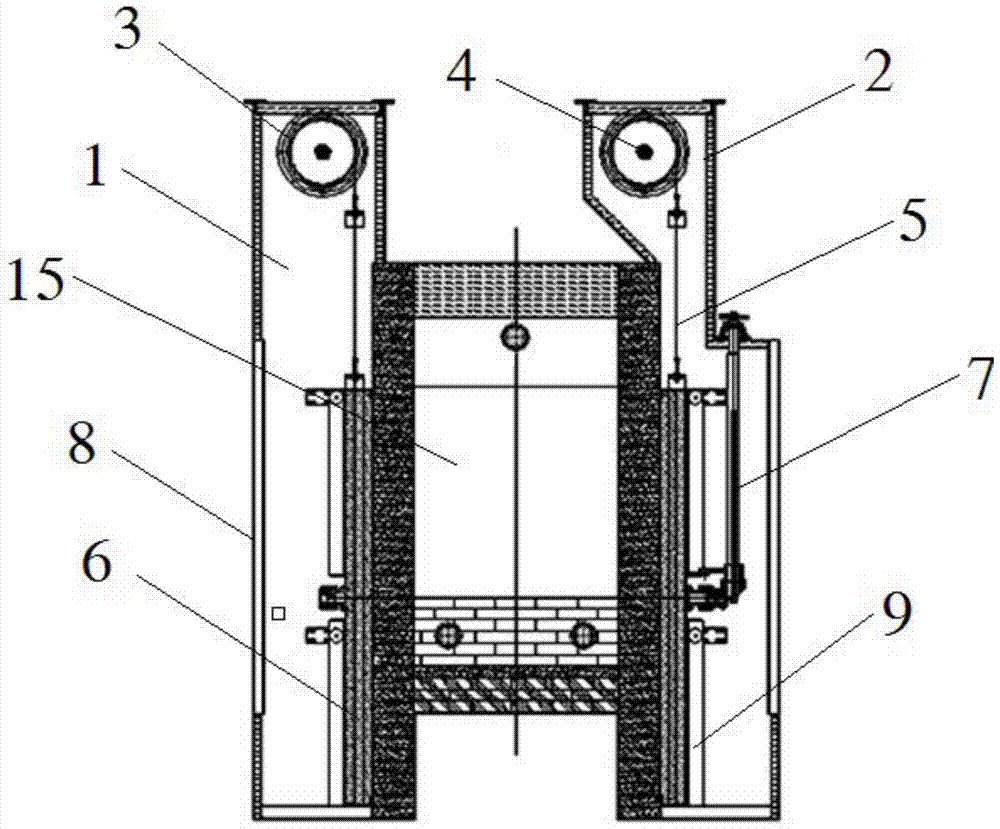

[0025] Embodiment 1: as Figures 1 to 2 As shown, the high-temperature rotary lifting mechanism described in Embodiment 1 includes a lifter 1 and a lifting area 15, and a plurality of heating elements, a plurality of thermocouples, and a plurality of cooling systems are arranged in the lifting area 15, and the lifting area 15 15 The top of the inner wall is provided with insulation material 13, and the bottom of the inner wall is provided with insulation material 13 and refractory insulation bricks 14 in turn. The elevator 1 includes a lifting device, and the lifting device includes a power output device. Shaft 4, each of the lifting rotating shafts 4 is arranged on two transmission sprockets 3, and the two lifting rotating shafts 4 are connected with the same power output device, and the four driving sprockets 3 are all connected by a chain 5 is connected with the lifting movable platform 6, and the two sides of the elevator 1 are provided with positioning wheels and slide ra...

Embodiment 2

[0028] Embodiment 2: as Figures 1 to 2As shown, the high-temperature rotary lifting mechanism described in Embodiment 2 is different from Embodiment 1 in that the elevator 1 includes a casing 2, and the casing 2 is provided with a maintenance door 8 and a maintenance manhole. An observation hole is arranged on the maintenance manhole.

Embodiment 3

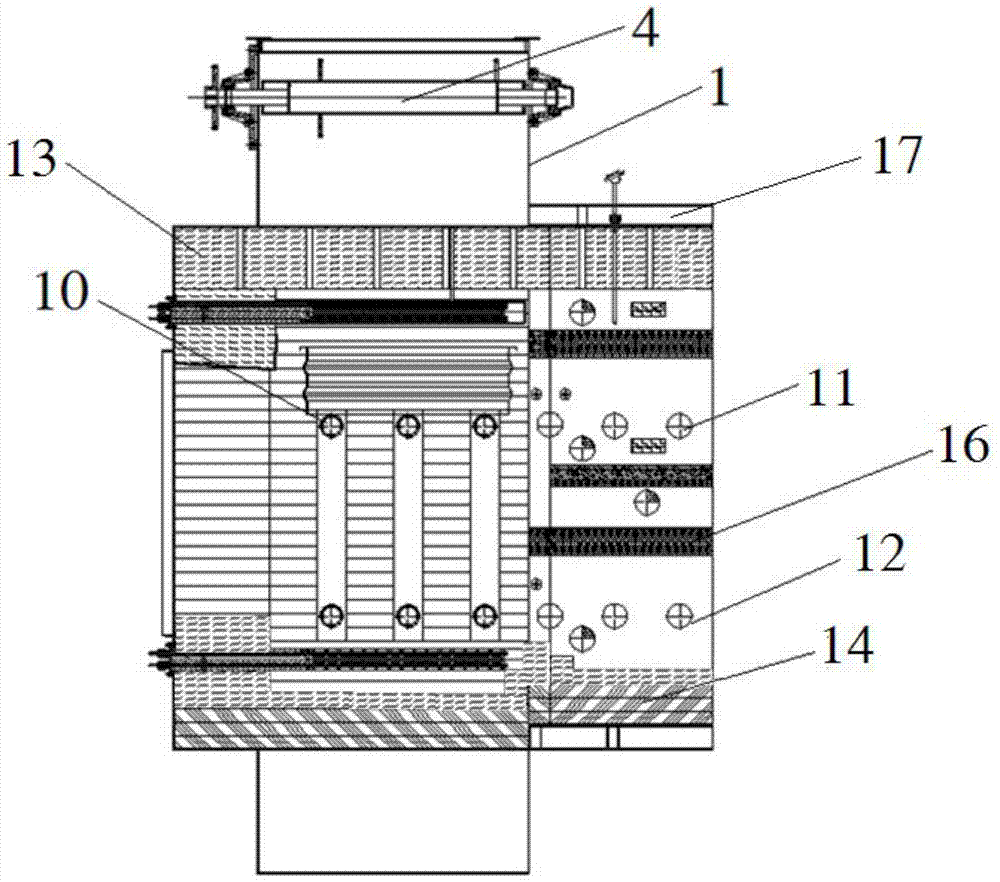

[0029] Embodiment 3: as Figure 1 to Figure 2 As shown, the high-temperature rotary lifting mechanism described in Embodiment 3 is different from Embodiment 1 in that one side of the lifting area 15 communicates with the double-layer heat treatment furnace 17, and the inside of the double-layer heat treatment furnace 17 is There are upper transmission rollers 11, lower transmission rollers 12, multiple heat insulation layers 16, multiple heating elements, multiple cooling systems, and multiple thermocouples. The top of the furnace is provided with an insulating material 13, and the bottom of the furnace is sequentially provided with There are insulation materials 13 and refractory insulation bricks 14, and at least one circulation fan is provided on the furnace roof of the heat treatment furnace 17. Among them, the metal workpiece is transferred from one end of the furnace body to the other end of the furnace body through the upper transmission idler 11, and then the metal wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com