A racetrack-shaped close-wound electromagnetic inductor

An electromagnetic inductor and densely wound technology, applied in the field of tank body welds, can solve problems such as human health damage, uneven magnetic field, uneven heating, etc., achieve high safety, ensure health, and reduce exhaust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

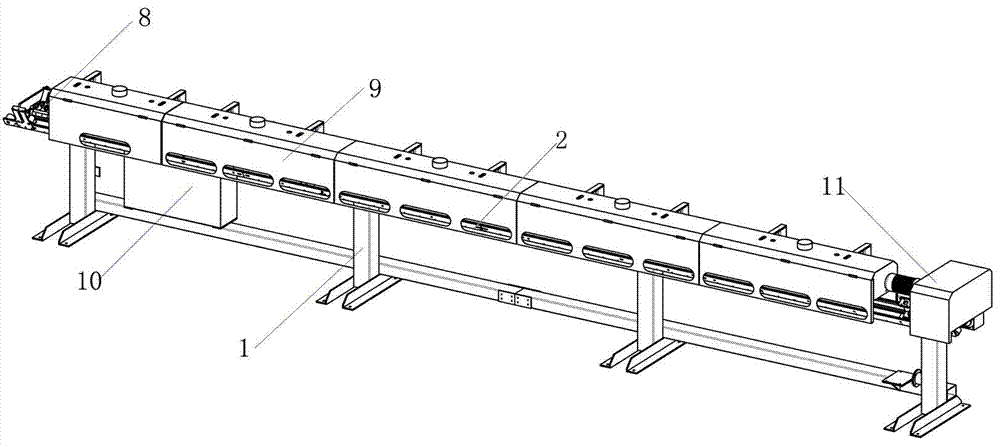

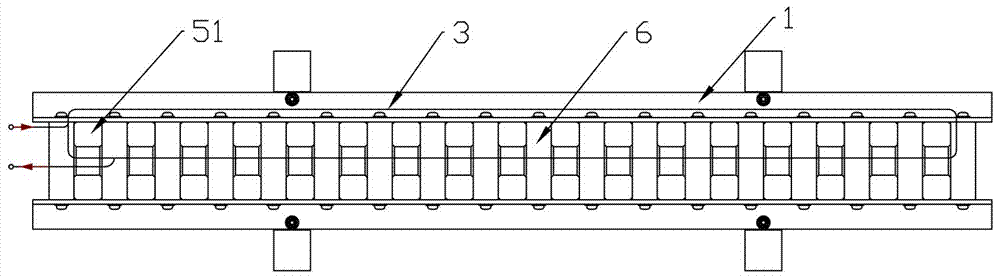

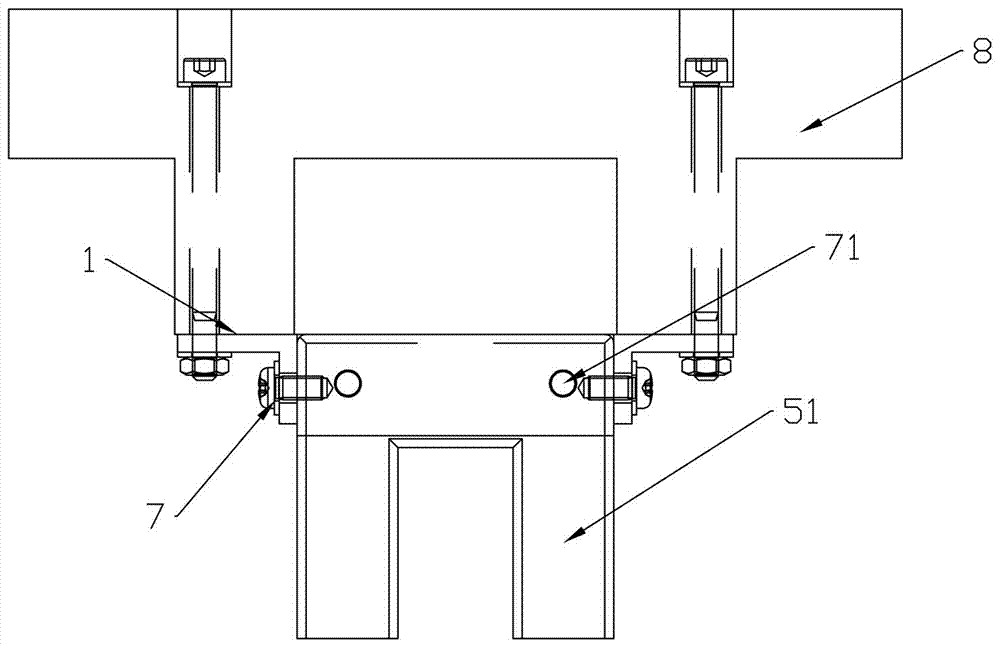

[0026] see Figure 1~4 As shown, it is a structural schematic diagram of the present invention, a racetrack-shaped close-wound electromagnetic inductor, which mainly includes: a bracket, a magnetic core group, a wire and a power supply, and the magnetic core group is arranged by U-shaped magnetic cores. There are spacers between the magnetic core groups, which can effectively prevent the mutual interference between the magnetic core groups. The wires surround the magnetic core feet on one side of the U-shaped magnetic core. The core legs surrounded by the rear magnetic core group are not on the same side to ensure that the tank body is dried evenly during transportation. The two ends of the above-mentioned wires are connected to the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com