Continuous casting crystallizer covering slag special for IF steel

A technology for continuous casting mold and mold flux, which is applied to the field of mold flux for continuous casting molds for IF steel, can solve the problems of poor heat transfer performance, high melting point, low mold flux basicity, etc., so as to reduce production costs and use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

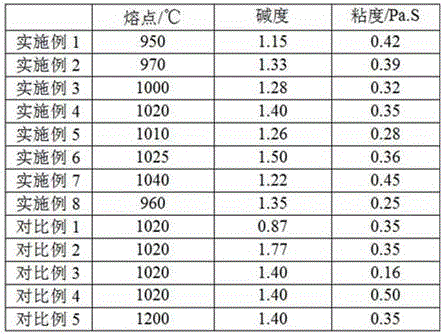

Examples

Embodiment 1

[0030] A mold powder for continuous casting mold for IF steel, made of the following raw materials in parts by weight: 4 parts of fluorite, 5 parts of cement clinker, 6 parts of white alkali, 1 part of carbon black, 55 parts of wollastonite, bentonite 4 parts, 2 parts of carbonless soot, 2 parts of calcite, 7 parts of manganese carbonate, 10 parts of bauxite and 1 part of binder.

[0031] Wherein the binder is sodium hydroxymethyl cellulose.

[0032] The chemical composition and weight percentage of the tested product are: CaO: 38.1%, SiO 2 : 33.0%, MgO: 8.9%, Al 2 o 3 : 8.8%, Na 2 O: 3.1%, MnO2 : 3.5%, F: 2.5%, C solid: 1.2%, the balance is unavoidable impurities, basicity: 1.15, melting point: 950°C, viscosity at 1300°C: 0.45Pa.S.

Embodiment 2

[0034] A mold powder for continuous casting mold for IF steel, made of the following raw materials in parts by weight: 7 parts of fluorite, 6 parts of cement clinker, 5 parts of white alkali, 1 part of carbon black, 56 parts of wollastonite, bentonite 5 parts, 3 parts of carbonless soot, 3 parts of calcite, 6 parts of manganese carbonate, 9 parts of bauxite and 1.5 parts of binder.

[0035] Wherein the binder is sodium hydroxymethyl cellulose.

[0036] The chemical composition and weight percentage of the tested product are: CaO: 39.5%, SiO 2 : 29.6%, MgO: 8.6%, Al 2 o 3 : 8.4%, Na 2 O: 3.5%, MnO 2 : 3.2%, F: 4.8%, C solid: 1.0%, the balance is unavoidable impurities, basicity: 1.33, melting point: 970°C, viscosity at 1300°C: 0.39Pa.S.

Embodiment 3

[0038] A mold powder for continuous casting mold for IF steel, made of the following raw materials in parts by weight: 6 parts of fluorite, 7 parts of cement clinker, 4 parts of white alkali, 3 parts of carbon black, 57 parts of wollastonite, bentonite 6 parts, 4 parts of carbonless soot, 4 parts of calcite, 5 parts of manganese carbonate, 8 parts of bauxite and 2 parts of binder.

[0039] Wherein the binder is sodium lignosulfonate.

[0040] The chemical composition and weight percentage of the tested product are: CaO: 40.6%, SiO 2 : 31.8%, MgO: 7.6%, Al 2 o 3 : 5.4%, Na 2 O: 3.1%, MnO 2 : 3.4%, F: 4.6%, C solid: 1.9%, the balance is unavoidable impurities, basicity: 1.28, melting point: 1000°C, viscosity at 1300°C: 0.32Pa.S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com