Method for prolonging service-life of grinding pad in chemical-mechanical polishing

A technology of chemical machinery and grinding pads, which is applied in the direction of grinding devices, grinding machine tools, grinding/polishing equipment, etc., can solve the problems of waste, high local loss of grinding pads, and affecting the life of grinding pads, so as to reduce production costs and improve cutting effect. Average, life-prolonging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

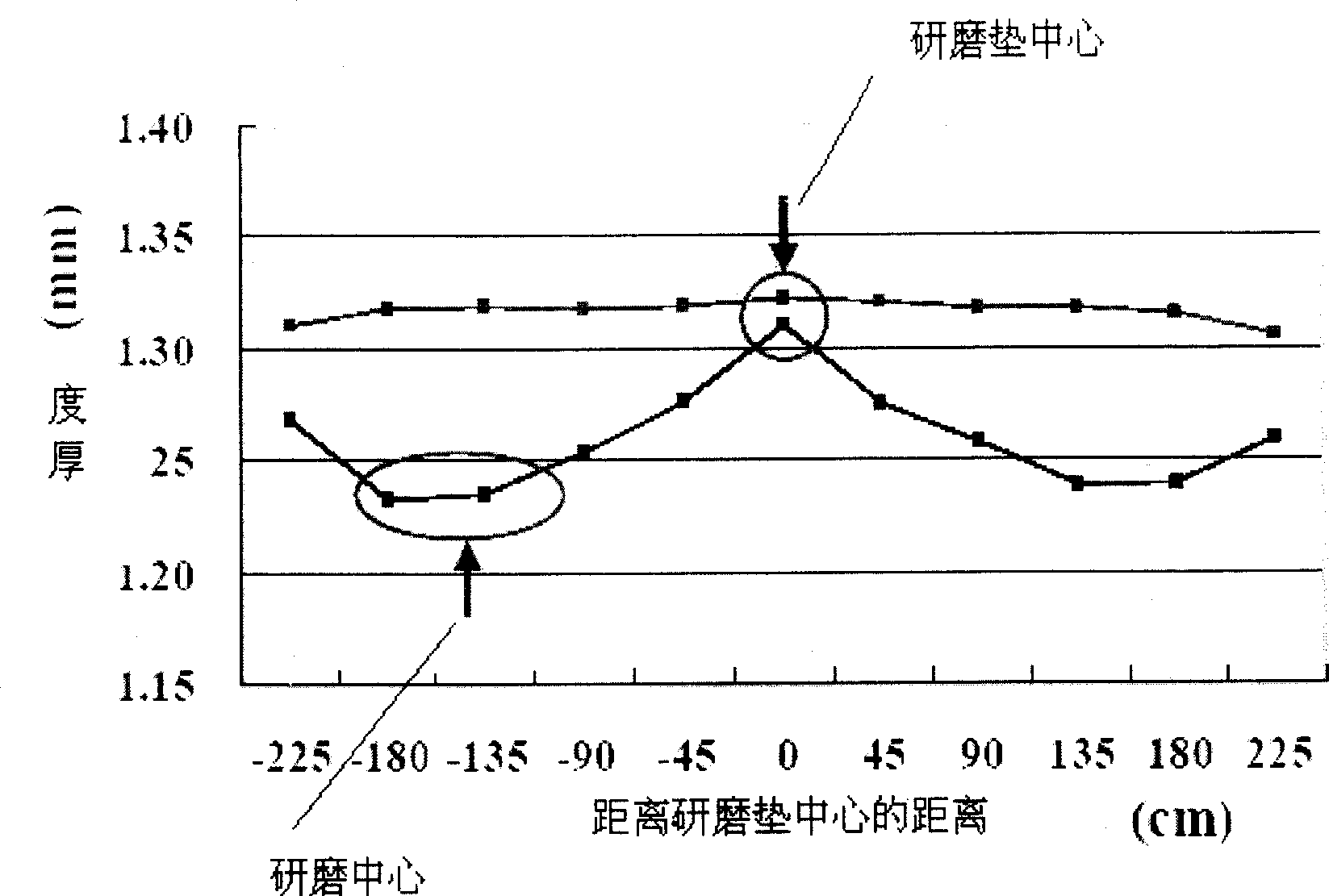

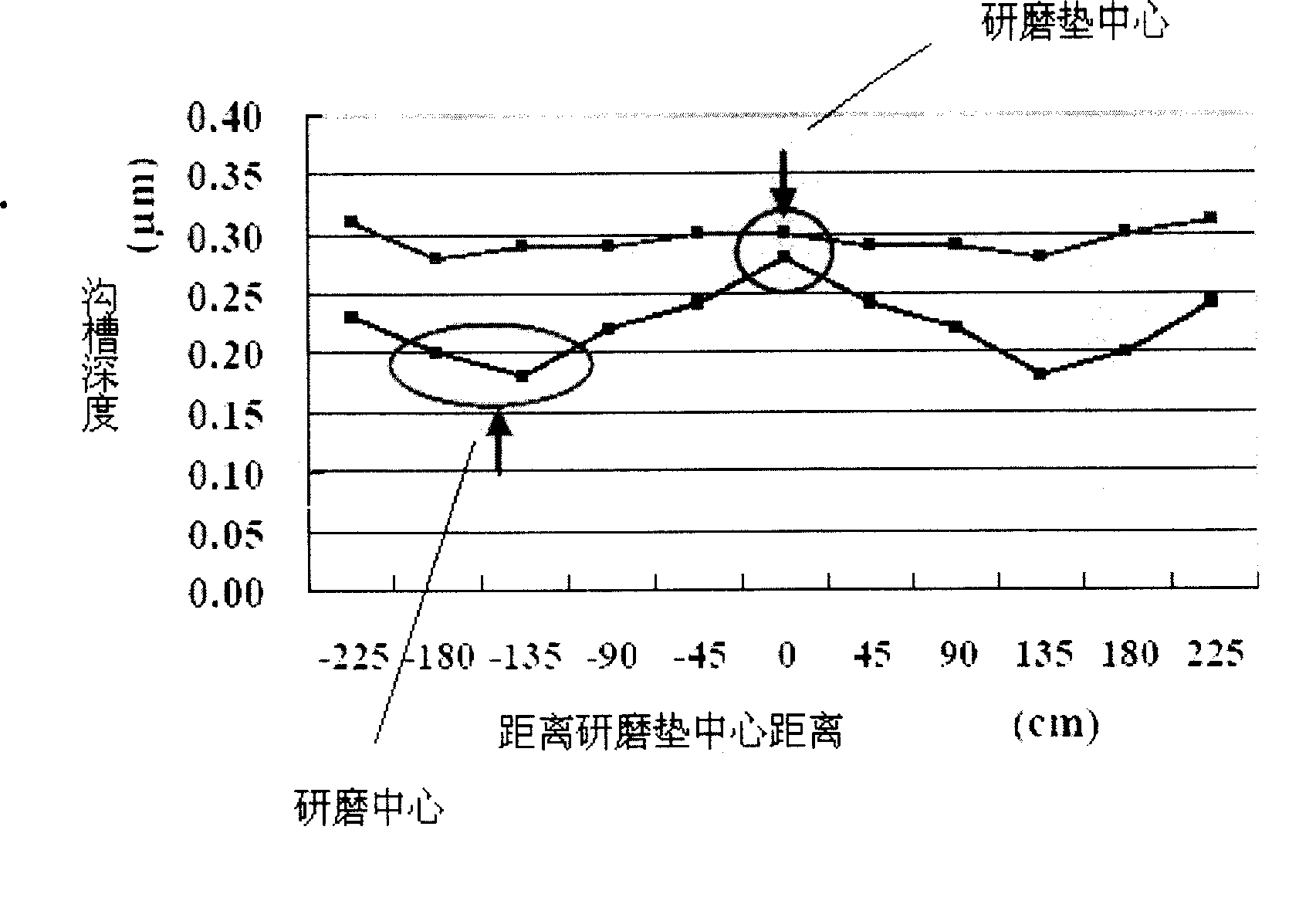

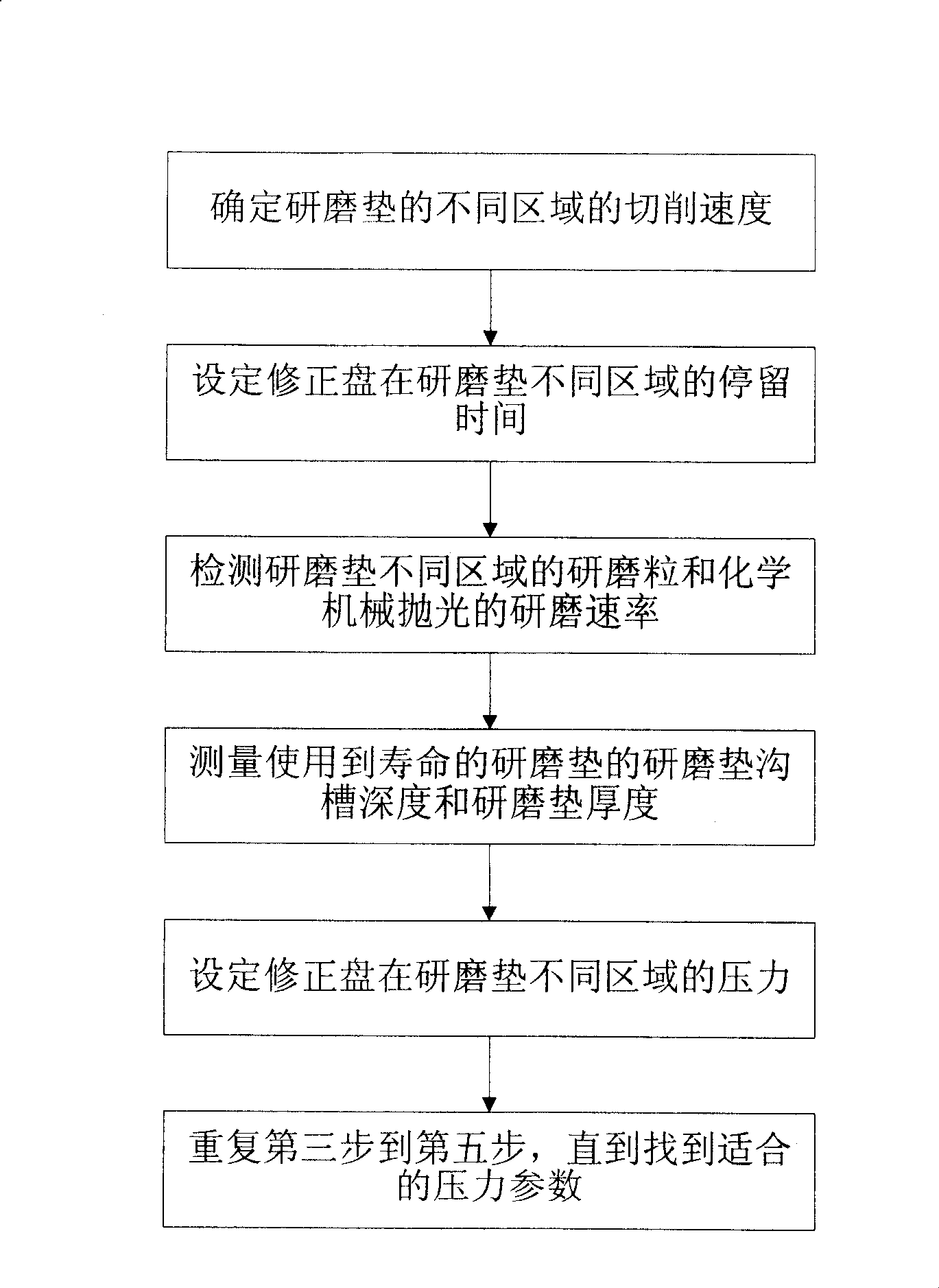

[0011] image 3 It is a schematic flow chart of the method of the present invention. like image 3 As shown, a method for prolonging the life of a polishing pad in chemical mechanical polishing includes the following steps: the first step is to measure the depth of the groove of the polishing pad and the thickness of the polishing pad of the polishing pad in different periods of use, thereby determining the cutting of different regions of the polishing pad Speed; the second step is to set the residence time of the correction disc in different areas of the polishing pad; the third step is to detect the abrasive grains in different areas of the polishing pad and the grinding rate of chemical mechanical polishing; the fourth step is to measure the service life of the polishing pad The groove depth of the polishing pad and the thickness of the polishing pad; the fifth step is to set the pressure of the correction disc on different areas of the polishing pad according to the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com