Pallets and assembly comprising the same

A pallet and top plate technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of easy deformation, complex design, inability to use, etc., and achieve the effect of simple rolling, large design freedom, and light design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

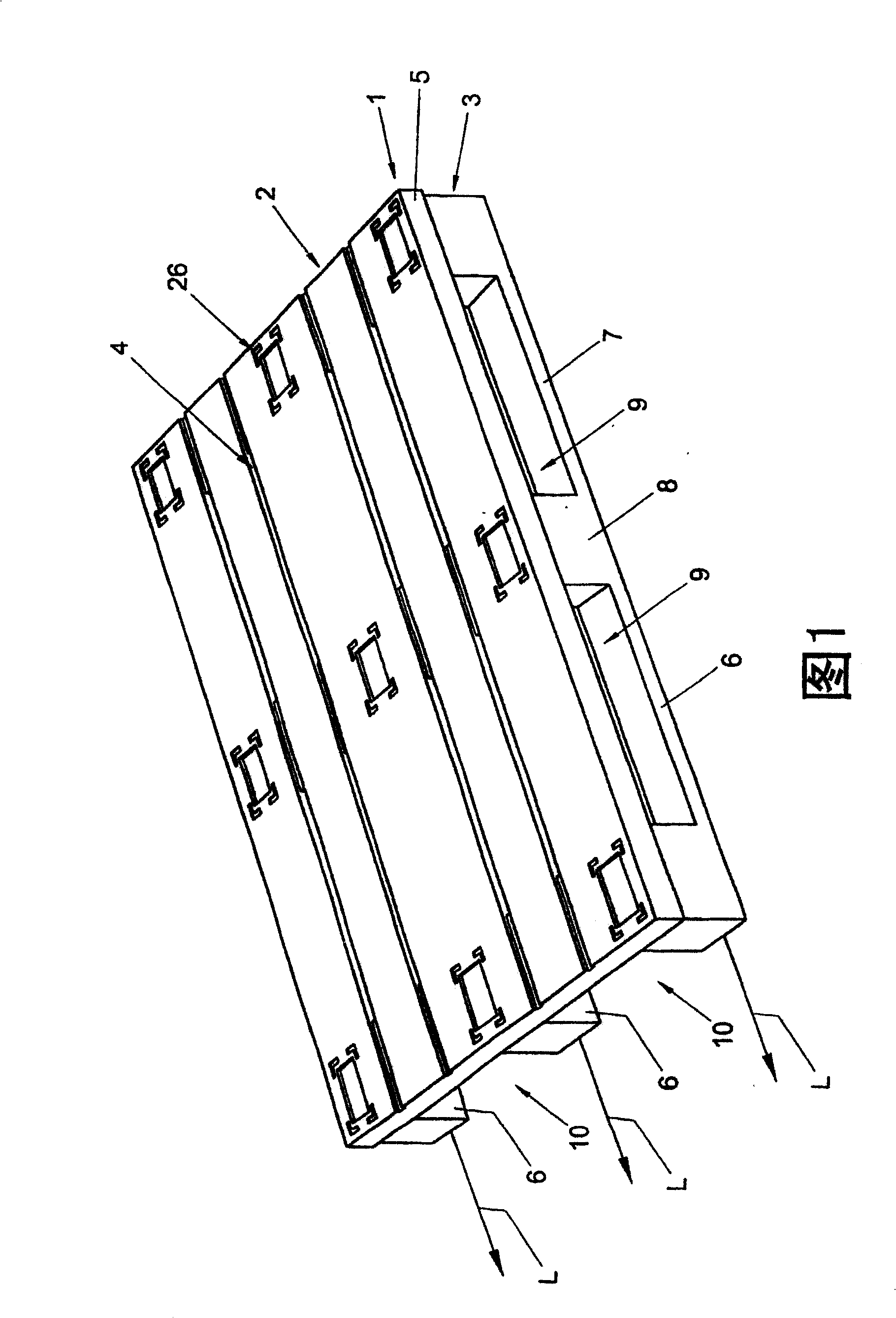

[0036]Figure 1 shows a top perspective view of a pallet 1 according to the invention, manufactured from a plastic such as PE, PP, ABS, PC or any other suitable plastic or a combination of these plastics for larger components . The pallet 1 is formed by a top plate 2 and a support structure 3 which are placed one on top of the other and connected to each other by means of eg snapping means, clamping means, or eg by gluing, welding or the like. The top plate 2 is essentially closed and has slot-shaped openings 4 , but it can also be designed in a different way, for example with a honeycomb structure, protrusions, profiles or the like, if desired. Variations thereon will be readily apparent to those of ordinary skill in the art. At the edge, the top plate 2 is provided with a skirt 5 extending downwards. The support structure 3 comprises three longitudinal beams 6 with a longitudinal direction L, which is schematically indicated by arrows L in FIG. 1 . The longitudinal beams 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com