Roll core and electrode body manufacturing method using same

A manufacturing method and electrode body technology, which can be applied in the manufacture of secondary batteries, winding/folding electrodes, battery electrodes, etc., can solve the problems of the deterioration of the quality of the electrode body, the tearing of the separator, and the increase in the cost of the winding core, and can suppress the damage to the ring. , The effect of preventing slippage and preventing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

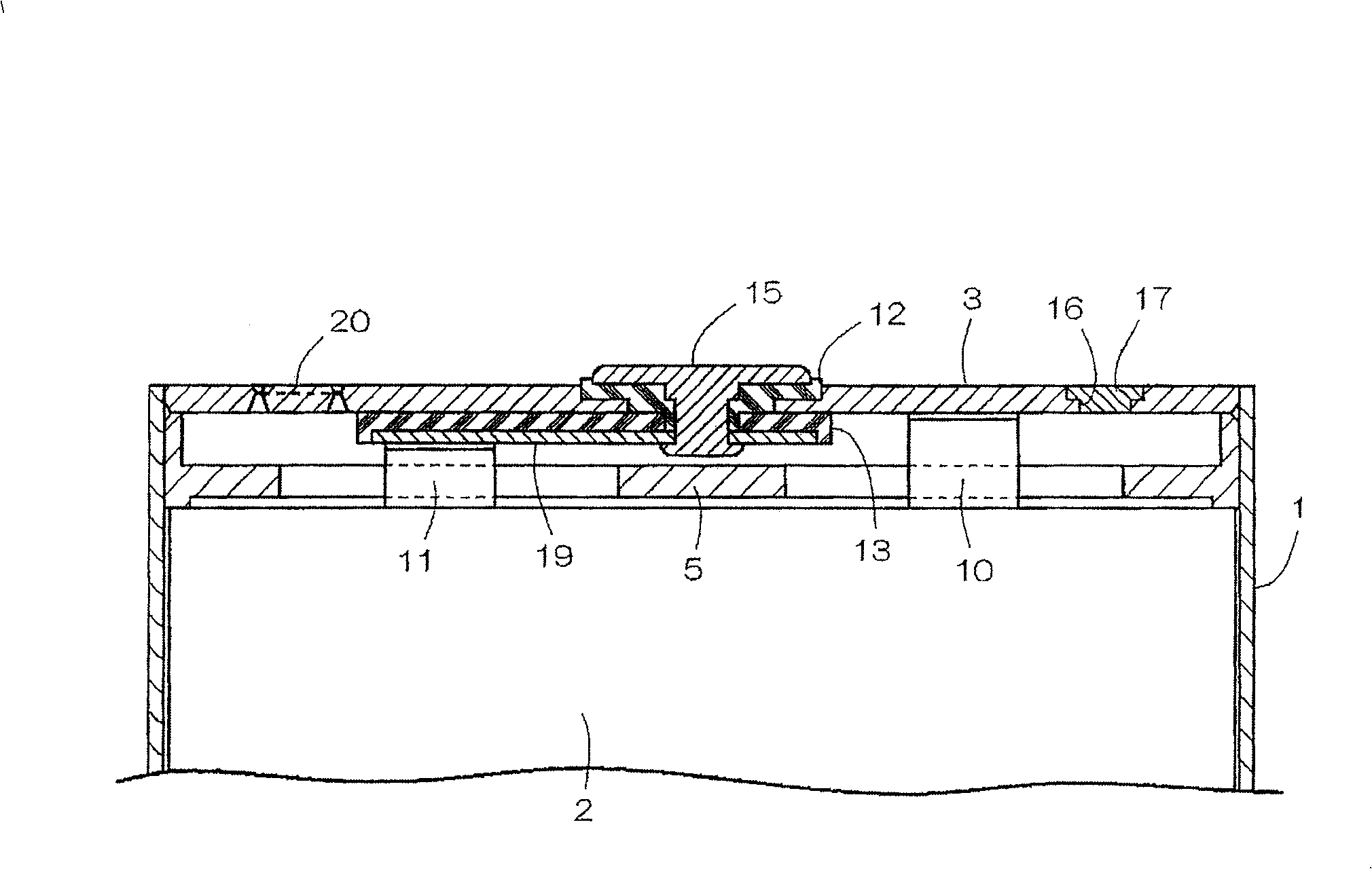

[0027] exist image 3 and Figure 4 Among them, the thin and sealed rectangular battery of the present invention comprises: a bottomed square battery case 1 with long left and right lateral openings; an electrode body 2 and a non-aqueous electrolyte contained in the battery case 1; the opening of the battery case 1 is blocked The upper left-right laterally long cover 3 and the plastic insulator 5 disposed inside the cover 3 are provided. The battery case 1 is a clad material made of nickel and aluminum, which is deep-drawn to form a thin case that is long in the vertical direction. The left and right width of the battery case 1 is 34 mm, the vertical height is 50 mm, and the front and rear thickness is 3.8 mm.

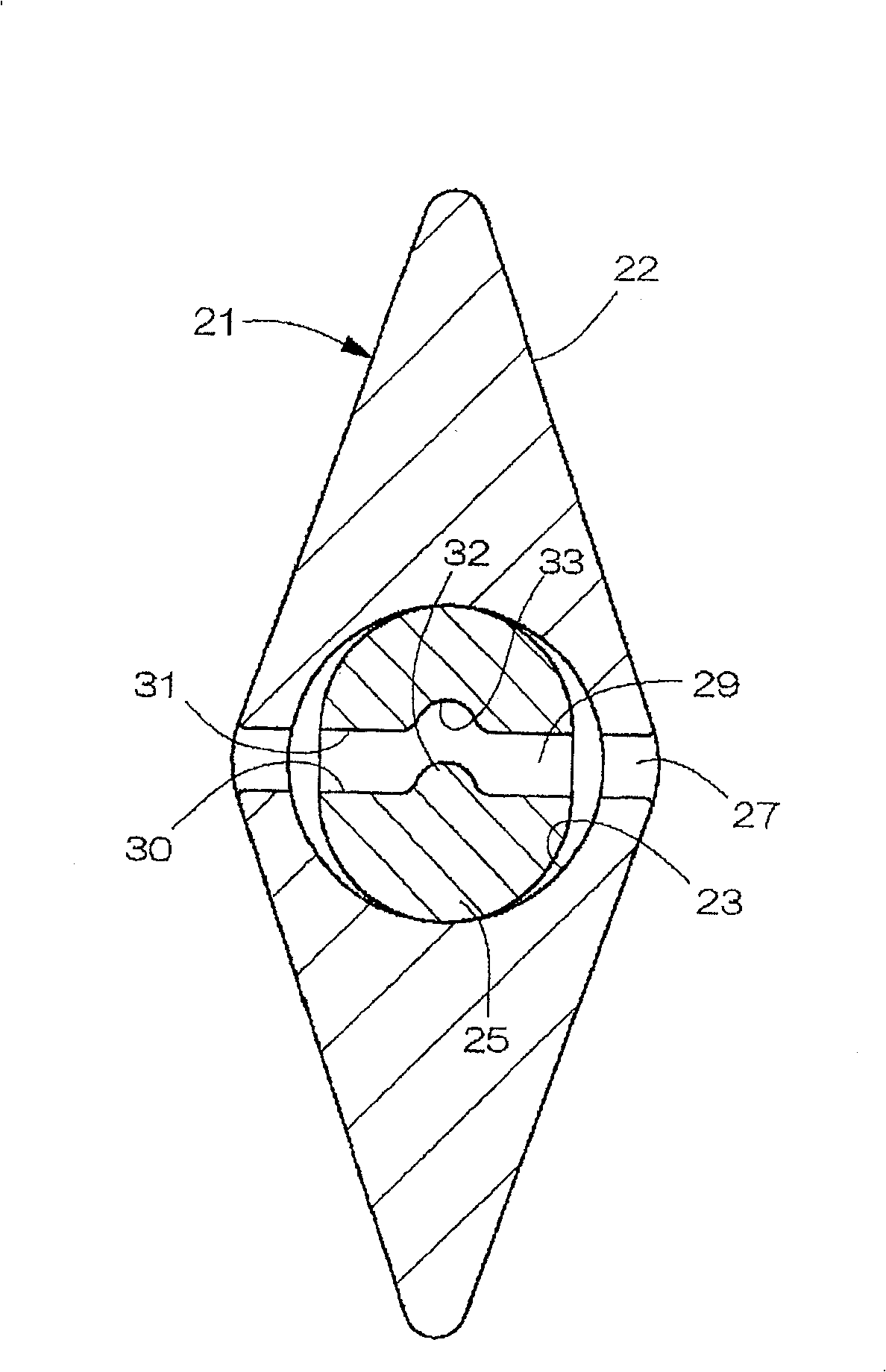

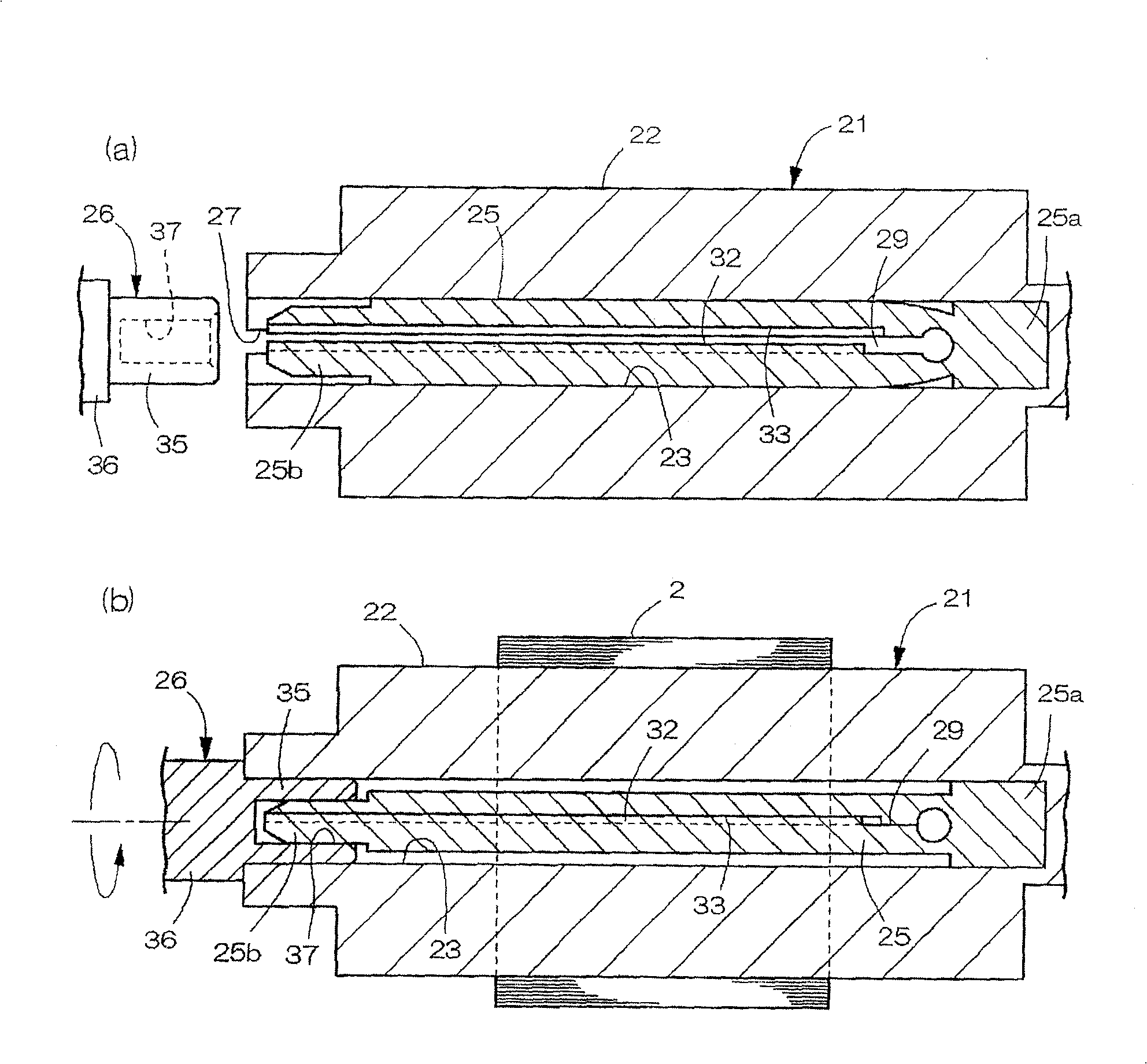

[0028] The electrode body 2 is formed by spirally winding a strip-shaped separator 9 made of a microporous polyethylene film (polyethylene film) between the strip-shaped positive electrode 6 and the strip-shaped negative electrode 7 . After being wound, the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com