Construction method of bridge concrete anti-collision guardrail

A technology of anti-collision guardrails and construction methods, applied in the direction of bridges, bridge parts, bridge construction, etc., to achieve the effects of saving manpower and time, strong applicability, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

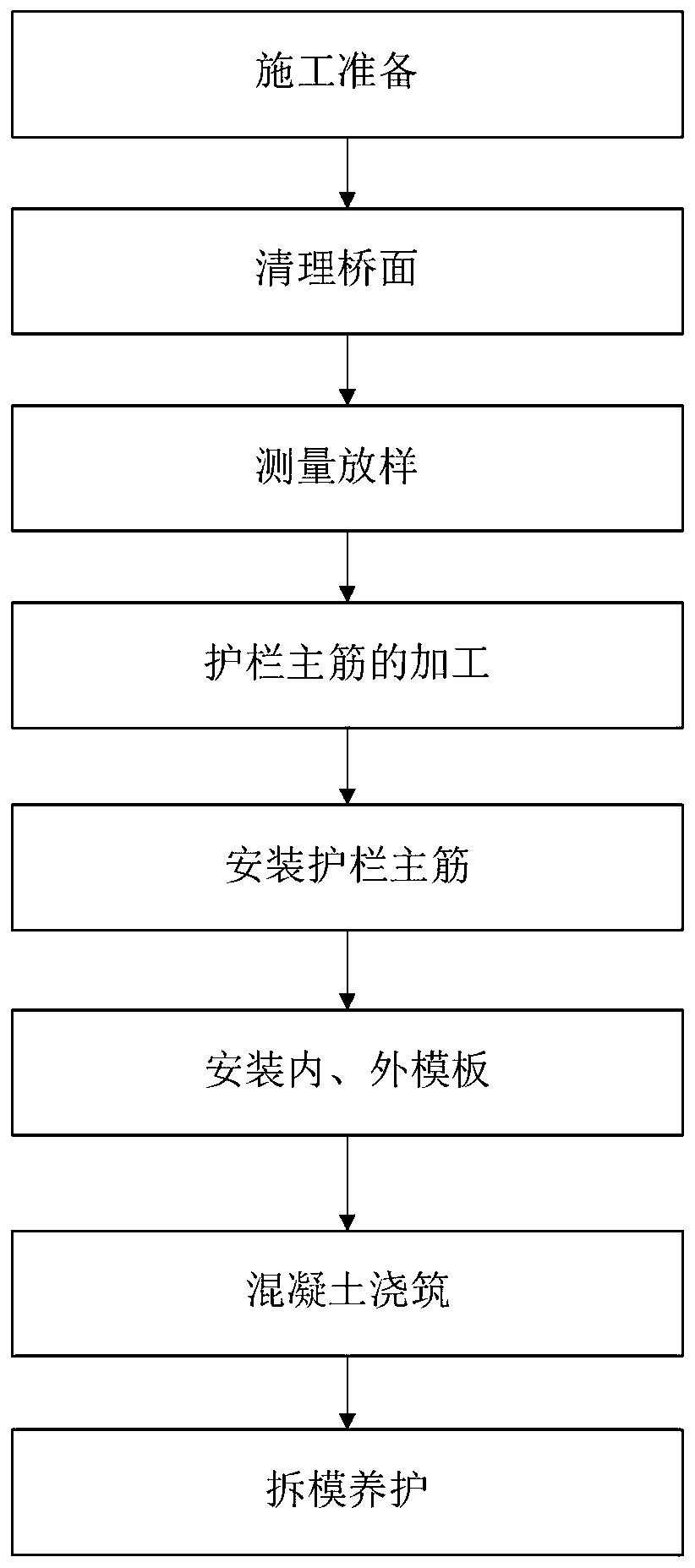

[0054] like Figures 1~12 As shown in the figure, a construction method of a bridge concrete anti-collision guardrail includes the following steps:

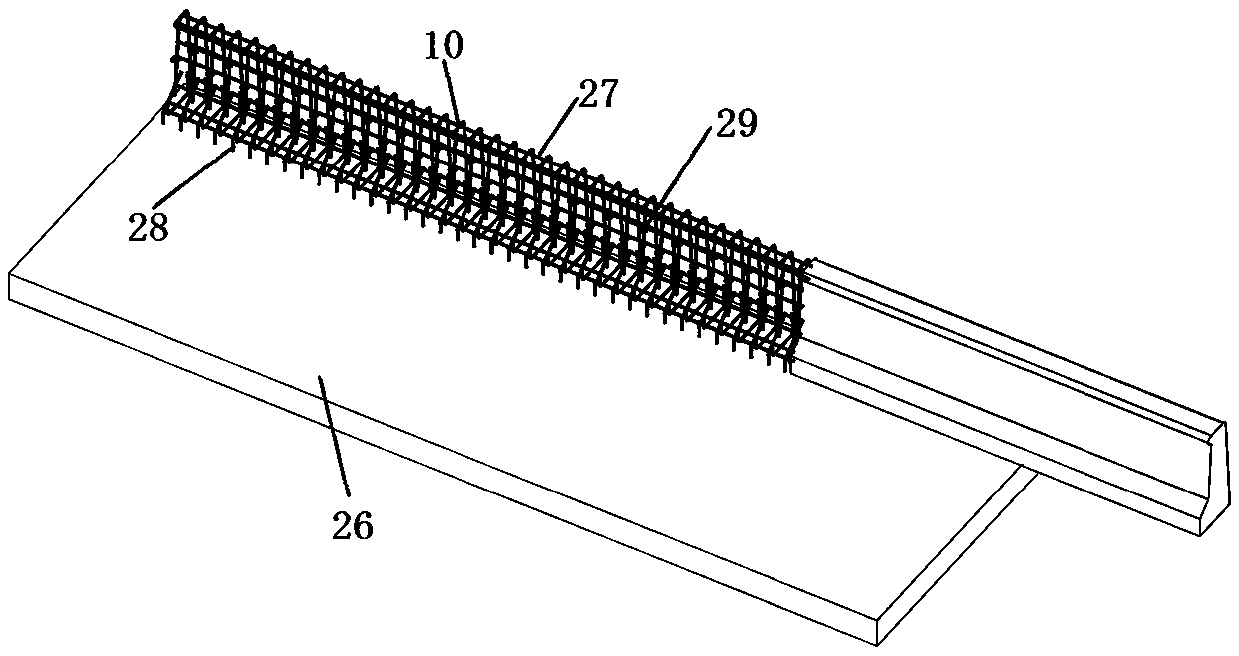

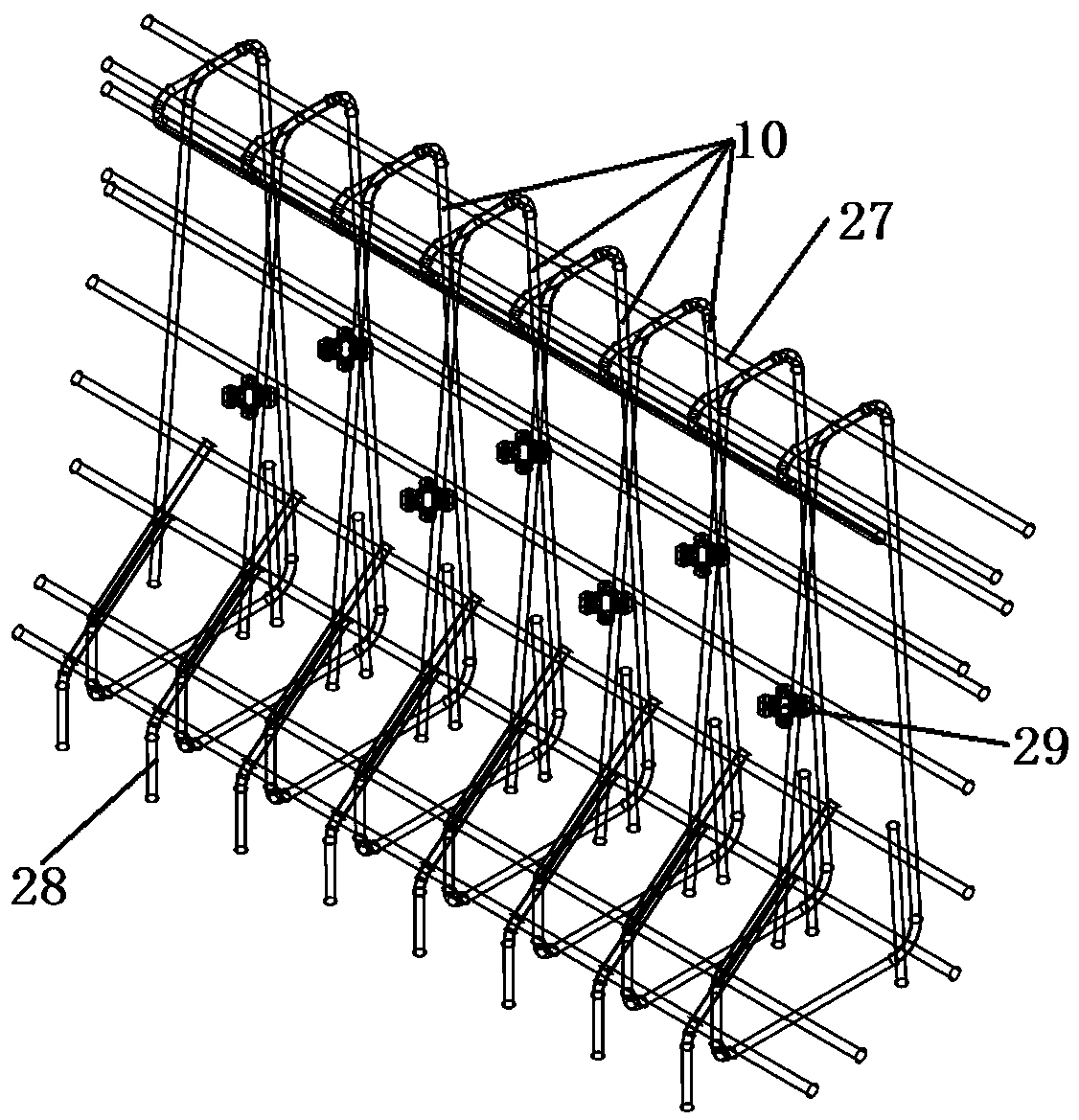

[0055] Step 1: Construction preparation; erect the beam plate 26 of the bridge according to the designed lay-out position, and pre-embed several guardrail pre-embedded ribs 28 in the side beams on both sides;

[0056] Step 2: Clean the bridge deck; use an air compressor to chisel and blow the bottom of the guardrail to be installed, and adjust the spacing of the pre-embedded ribs 28 of the adjacent guardrail to be l ; this spacing l for design size.

[0057] Step 3: Measure and stake out; use the total station to measure and locate the control points on the inside of the guardrail, set a control point every 10 meters for the straight section of the guardrail, and set a control point e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com