LCD panel and powering method thereof

A liquid crystal panel and electrical method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing manufacturing cost and high process difficulty, and achieve the effects of reducing difficulty, expanding viewing angle width, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

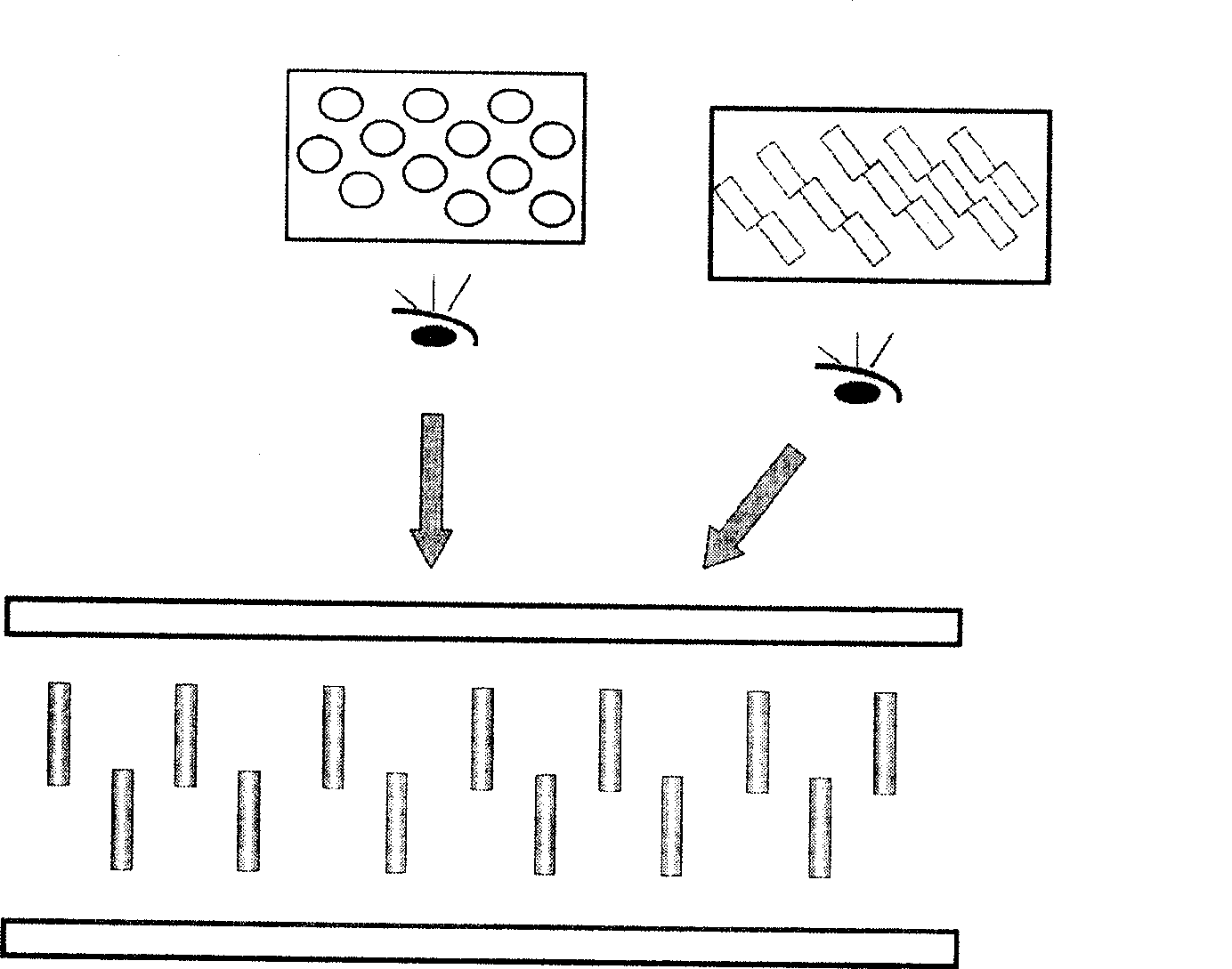

[0029] This embodiment provides a liquid crystal panel power-on method based on the liquid crystal panel of the present invention, such as Figure 6 shown, including:

[0030] Step 101 , after receiving a power-on command, power on one sub-electrode in each sub-pixel electrode of the liquid crystal panel.

[0031] Wherein, which sub-electrode is selected as the first sub-electrode to be powered on has no decisive influence on the purpose of achieving a wide viewing angle, and therefore, no limitation is made in this embodiment. However, it is preferable that the first electrified sub-electrodes of adjacent sub-pixels be symmetrical. For example, if Figure 7 As shown in , the partial electrodes marked with shaded grids are powered on at the current moment.

[0032] Step 102, when the preset power-on interval time arrives, power off the sub-electrode that has been powered on, and power on another sub-electrode adjacent to the sub-electrode that was powered on just now.

[0...

Embodiment 2

[0041] This embodiment provides another liquid crystal panel power-on method, and the only difference from Embodiment 1 is: when the sub-electrodes in each sub-pixel electrode are cycled and sequentially powered on, only all the sub-pixel electrodes in each sub-pixel electrode Part of the sub-electrodes in the sub-electrodes are powered on in turn.

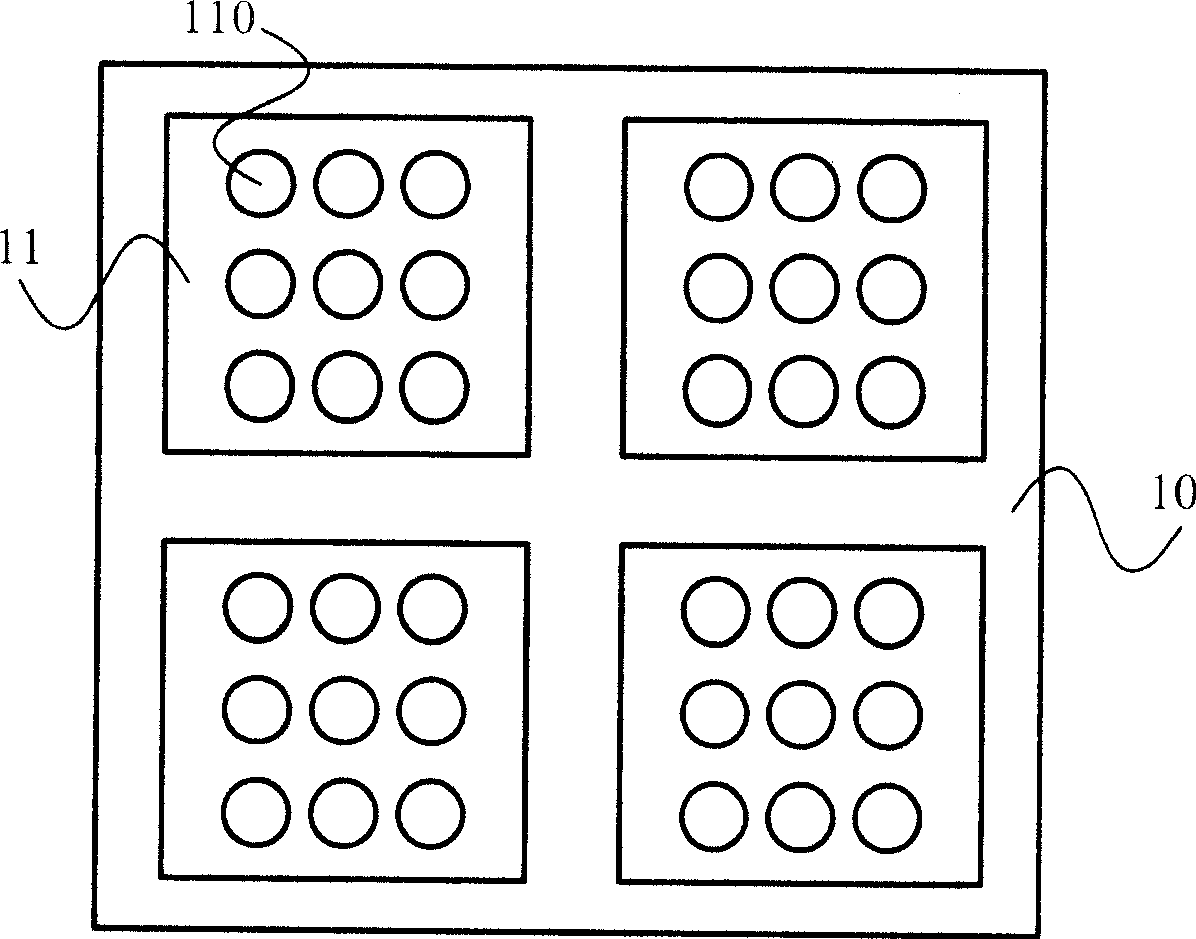

[0042] For example, if Figure 8 As shown, the sub-pixel electrodes of the sub-pixel 11 include 9 sub-electrodes 60-68. The sub-electrodes 64 , 65 and 66 are not always powered on, but only the sub-electrodes 60 , 61 , 62 , 63 , 67 and 68 are cyclically powered on.

[0043] Through the method described in this embodiment, the user can cycle and sequentially power on only some sub-electrodes according to the requirement of the viewing angle width of the liquid crystal panel. For example, if only the viewing angle width of the lower part of the liquid crystal panel is required in practical applications, only the sub-electrodes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com