Pre-injection molding type MINI LED packaging substrate

A packaging substrate and pre-injection technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of low reliability, large pixel pitch, low resolution, etc. The effect of a wide viewing angle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, the technical solutions in the embodiments in the embodiments will be described in contemplation in conjunction with the drawings of the present invention.

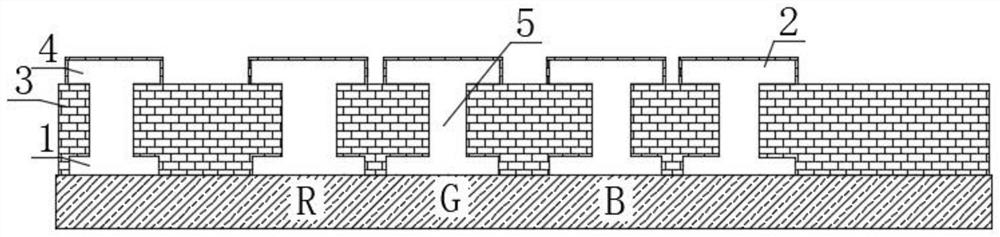

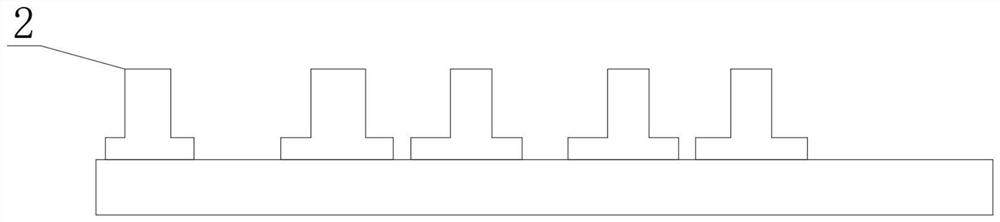

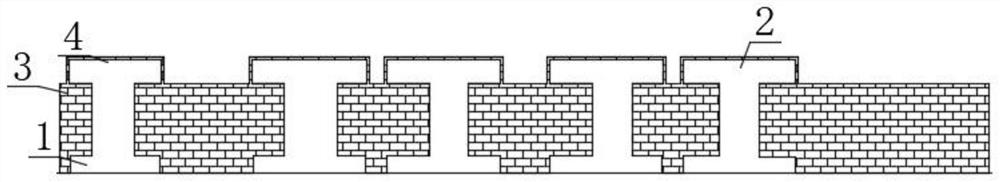

[0045] See Figure 1 ~ 5 In the present invention, the pre-plastic MINI LED package substrate includes pad 1 and package line structure 2, and the pad 1 is formed by etching, and the gap of the package line structure 2 is filled with a polymer layer 3. The package line structure 2 is integrated with a plurality of pins 4, and the pad 1 is provided with a thermal post 5, and the spacing of adjacent pin 4 is less than 0.3 mm, and the package line structure 2 and the polymer layer 3 are coarse Treatment.

[0046] The flat packaging scheme is used to remove the traditional groove package design, which greatly widened the range of view, and the surface-roughened treatment process, the interface binding force of different materials is used by the specific surface area of the roughness. Increased, enhanced binding powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com