Device and method for eliminating trimmings from series of products, such as rolls or the like

A series of products, product technology, applied in the field of devices for removing chips or end trimming, to achieve the effect of compact devices and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

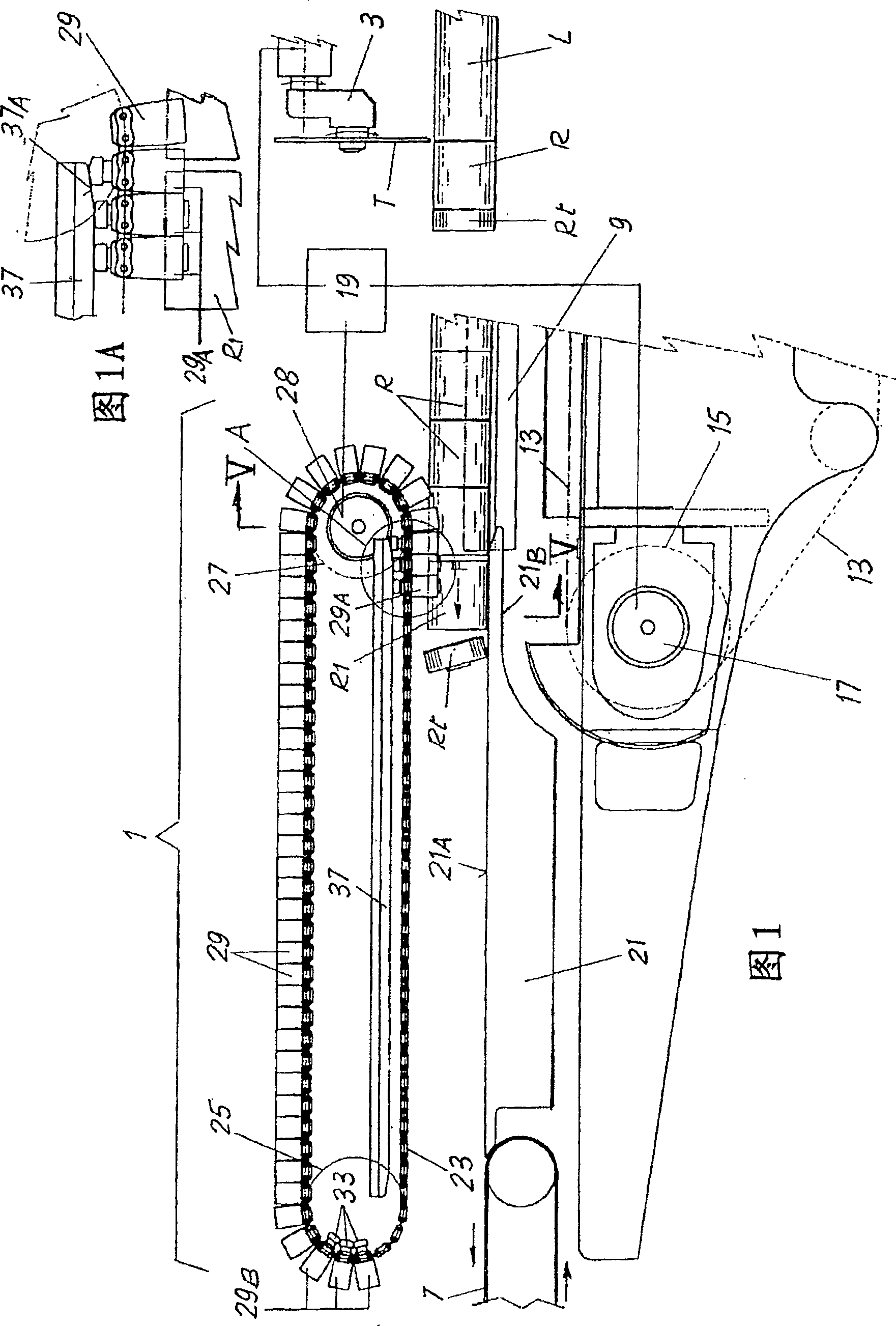

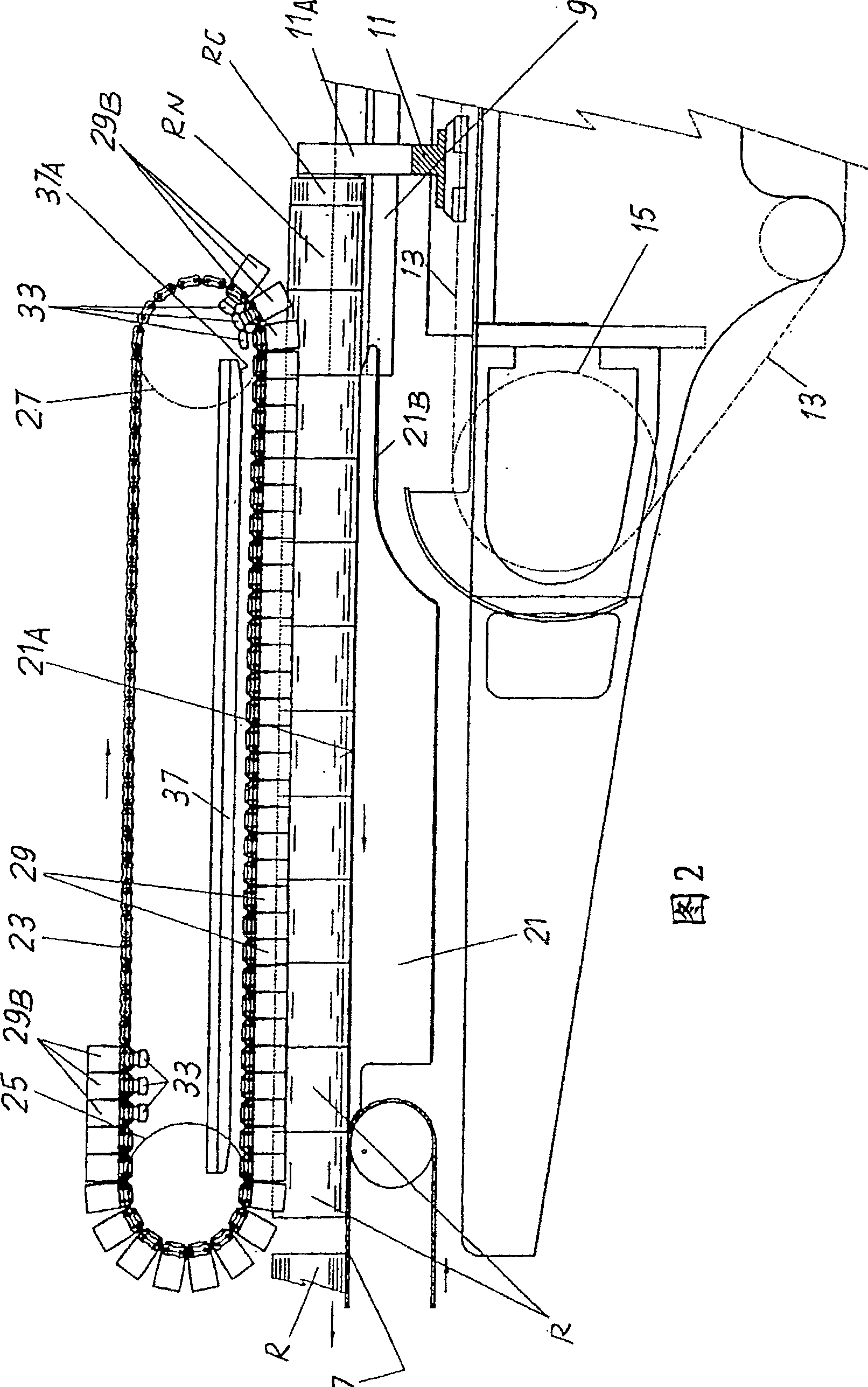

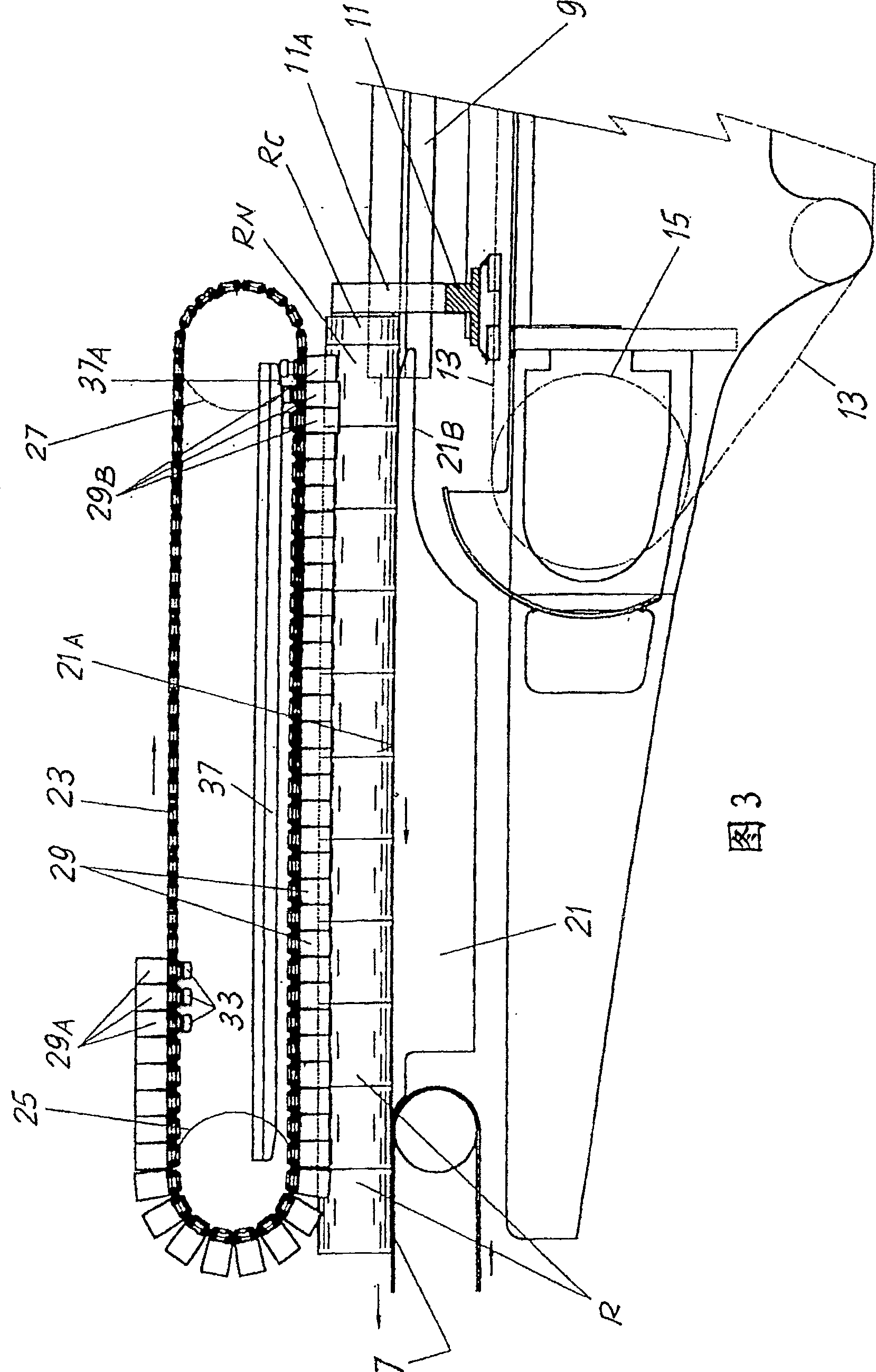

[0045] Specifically referring first to the schematic side views in FIGS. 1 to 4 and the cross-section in FIG. 5, the device generally indicated by 1 is located downstream of the only schematically indicated cutting machine 3, which includes a circular blade T or Other equivalent cutting members, such as band saws, to divide the round material L of considerable length into a series of rolls R of the same length as the final product. The cutting machine 3 also generates a head cut edge Rt and a tail cut edge Rc for each round material that must be removed from the device 1, while the rolls R must be conveyed to the conveyor 7, which then directs them towards the known type And the packaging machine not shown conveys. This type of cutting machine is known and will not be described here.

[0046] The cutting machine 3 may have one or more channels. The example shown shows only two adjacent channels (Figure 5), along which the circular material cut simultaneously by the cutting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com