Non-failure biogas fermentation tank

A biogas fermentation, trouble-free technology, applied in the direction of gas production bioreactors, applications, organic fertilizers, etc., can solve the problems of ineffective disposal of human and livestock manure, sewage, inconvenient long-distance sending out for off-site use, production and living ecological environment pollution, etc. , to achieve a benign improvement of the soil ecological environment, an increase in the population and number of beneficial microorganisms, and good crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

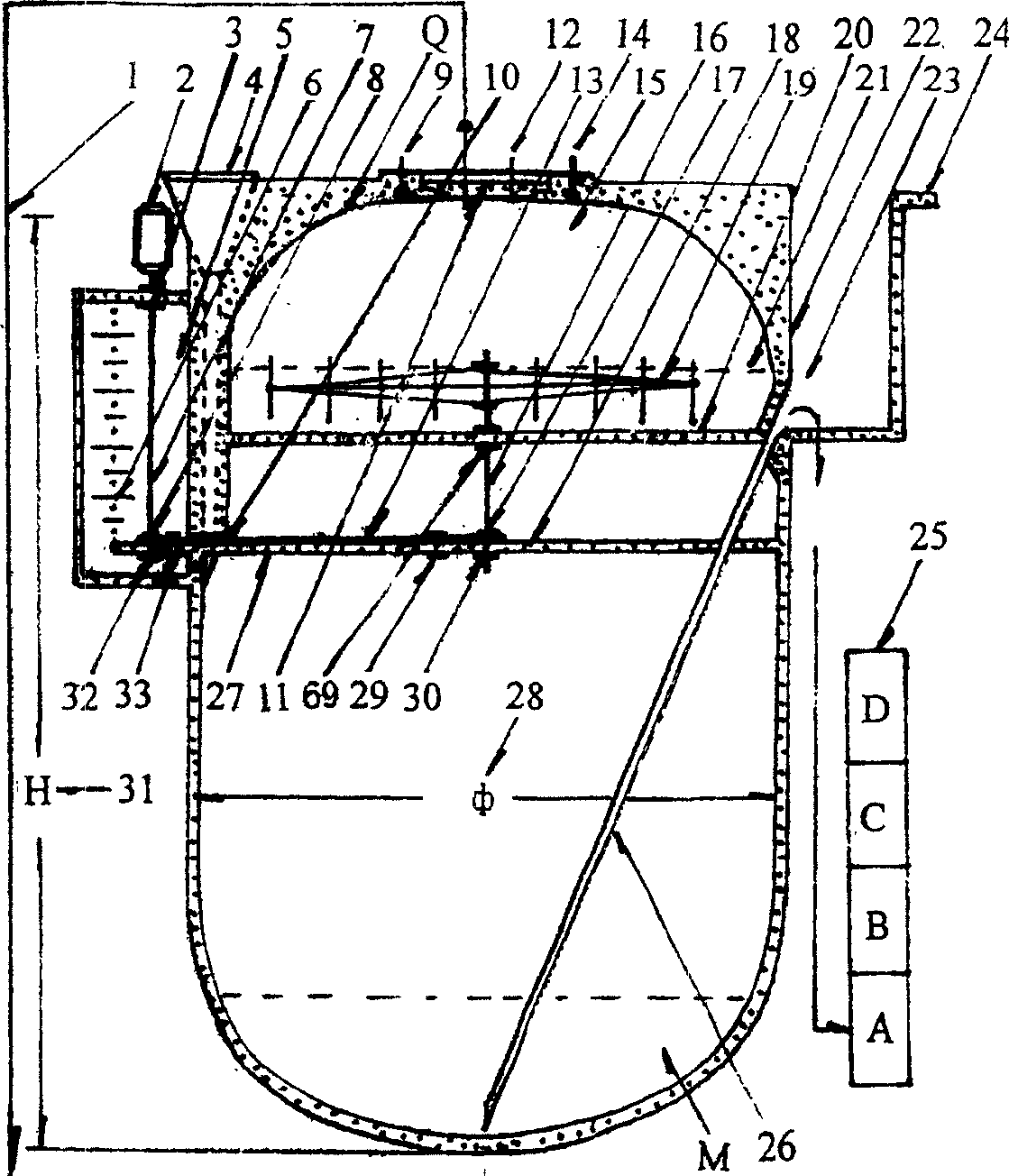

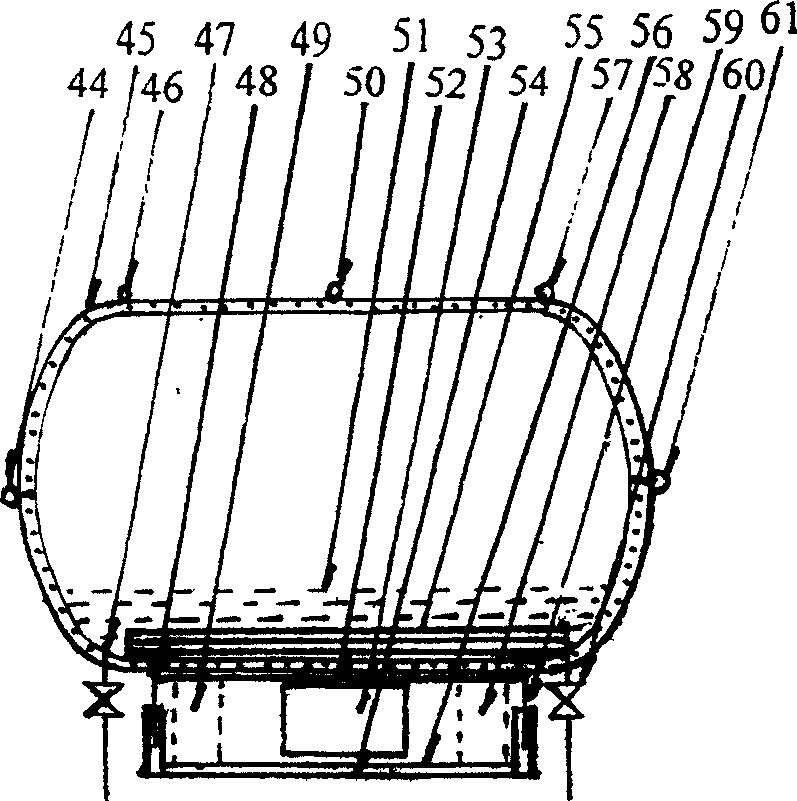

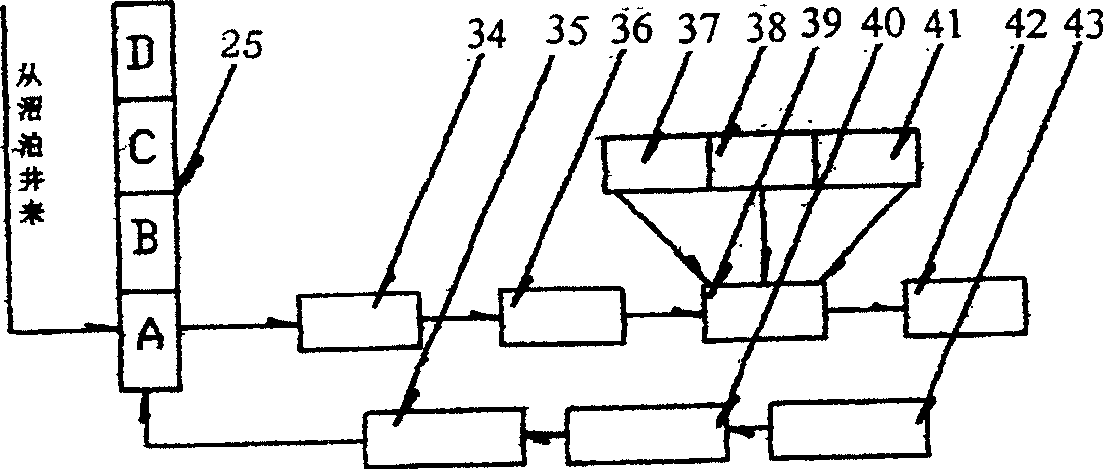

[0031] figure 1 Example: figure 1 It is the cross-sectional structure design drawing of a trouble-free biogas fermentation tank. The overall structure of a trouble-free biogas fermentation tank consists of a gas delivery pipe (1), a feed tank (Q), an inner sealing cover plate (11), a feed pipe (4), and a beam (18), two beams (20), biogas meal conduit (26), submerged power crust breaker (2), biogas slurry observation well (5), and marsh mooring well (23), and other hydraulic component structures Integrated built. The long cylindrical material tank (Q) is beneficial to reserve a gas storage chamber (15) on the upper part to collect biogas. The feed pipe (4) is vertically pre-buried and installed on the inner wall of the biogas tank. The feeding is smooth and labor-saving. During construction, One end of a beam (18) extends horizontally to the lower part of the biogas slurry observation well (5) below the biogas slurry communication hole (10), and is the position where some com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com